SBS-rubber powder composite modified asphalt and preparation method thereof

A technology of composite modified asphalt and rubber powder, which is applied in building components, building insulation materials, buildings, etc. It can solve the problems of poor storage stability, limited increase in high temperature softening point, high viscosity, etc., achieve stable performance and improve rutting resistance performance, low noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In the proportioning of the present embodiment, with 1.13kg as 1 part, the parts by weight of each component of the raw materials used are:

[0024] 21 parts of waste rubber powder

[0025] 2 parts of SBS modifier

[0026] Stabilizer 0.4 parts

[0027] Activator 0.04 part

[0028] 77 parts of asphalt.

[0029] Its preparation method is:

[0030] After compounding according to the above component ratios, preheat the asphalt to 180°C, add SBS modifier for high-speed shear dispersion for 20 minutes, add activator, rubber powder and stabilizer, and high-speed shear dispersion for 2 hours at 185°C. That is, the product of the present invention is obtained.

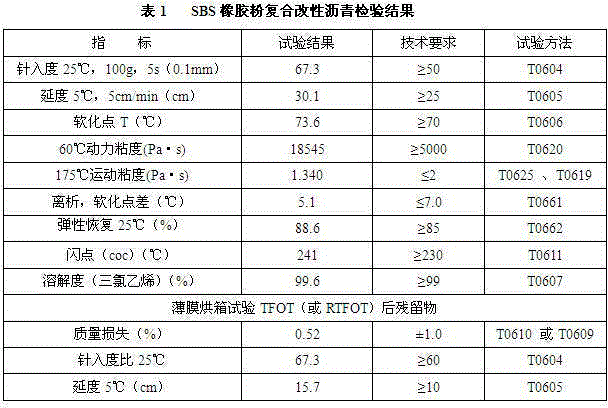

[0031] The main detection indicators of the SBS rubber powder composite modified asphalt prepared in this example are shown in Table 1.

[0032]

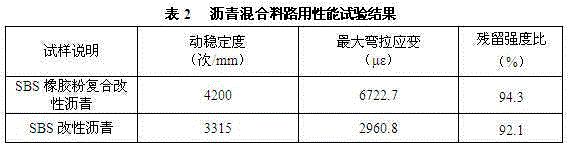

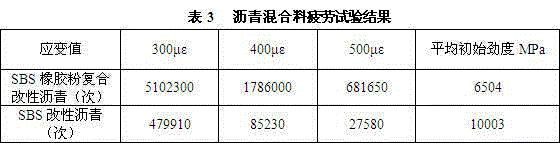

[0033] In order to verify the performance of the modified asphalt of the present invention, the inventor used the SBS rubber powder compound modified asphalt prepared...

Embodiment 2

[0039] In the proportioning of the present embodiment, with 0.87kg as 1 part, the parts by weight of each component of the raw materials used are:

[0040] 18 parts of waste rubber powder

[0041] 2.5 parts of SBS modifier

[0042] Stabilizer 0.3 parts

[0043] Activator 0.03 part

[0044] 80 parts of asphalt.

[0045] Its preparation method is identical with embodiment 1.

[0046] After testing, after adopting the SBS rubber powder composite modified asphalt of the present invention, the dynamic stability of the asphalt mixture, the failure strain, the residual strength ratio, the performance index of the fatigue action times are compared with the test results of the SBS modified asphalt mixture. The indicators have been greatly improved.

Embodiment 3

[0048] In the proportioning of the present embodiment, with 0.85kg as 1 part, the parts by weight of each component of the raw materials used are:

[0049] 15 parts of waste rubber powder

[0050] 3 parts of SBS modifier

[0051] Stabilizer 0.2 parts

[0052] Activator 0.03 parts

[0053] 82 parts of asphalt.

[0054] Its preparation method is identical with embodiment 1.

[0055] After testing, after adopting the SBS rubber powder composite modified asphalt of the present invention, the dynamic stability of the asphalt mixture, the failure strain, the residual strength ratio, the performance index of the fatigue action times are compared with the test results of the SBS modified asphalt mixture. The indicators have been greatly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com