Durable rubber asphalt and preparation method thereof

A rubber asphalt, durable technology, applied in the composition and preparation of rubber powder modified asphalt, can solve the problems of poor low temperature crack resistance and shortened service life of modified asphalt, achieve excellent low temperature crack resistance, reduce product Cost, Pollution Reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

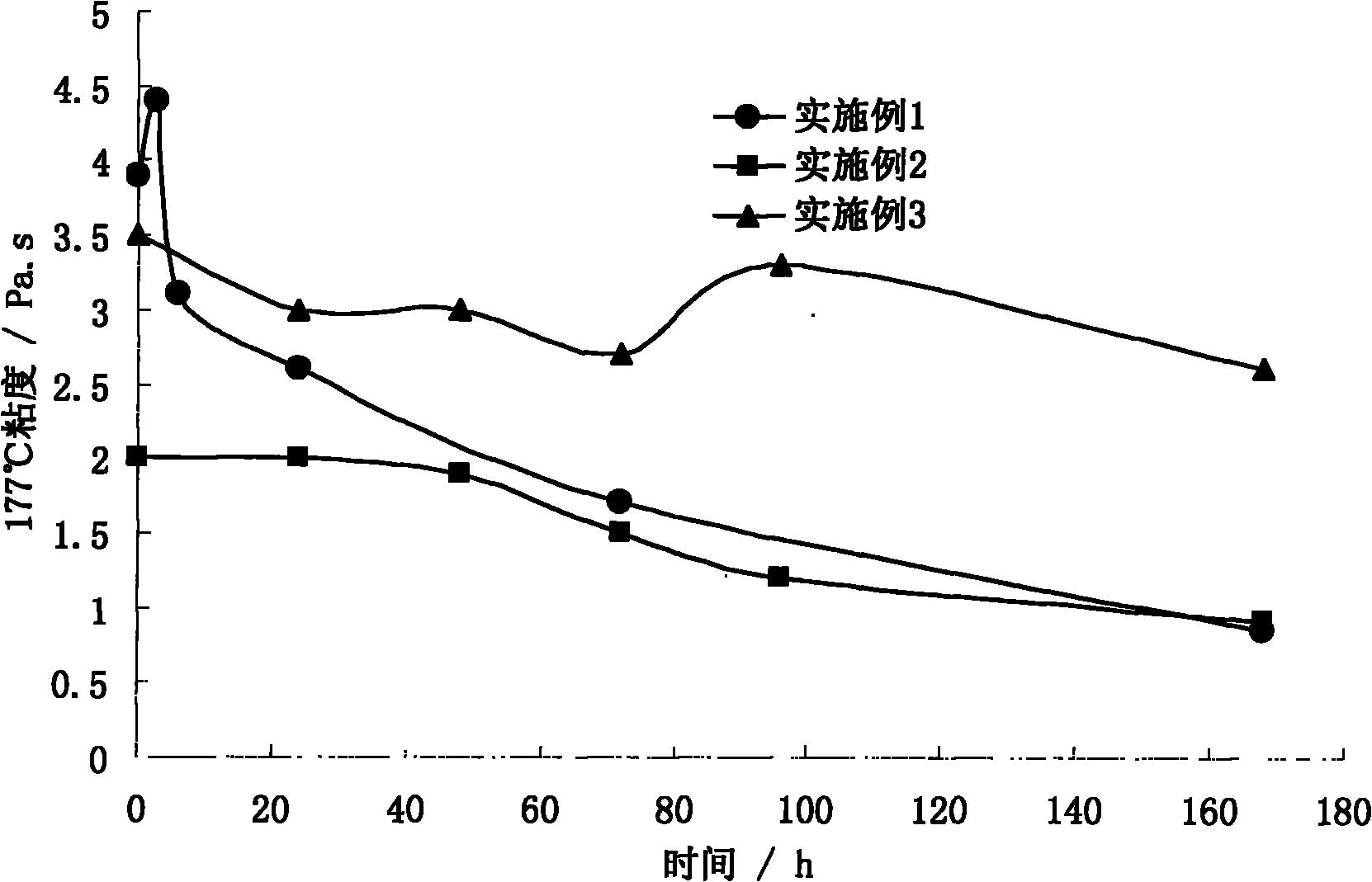

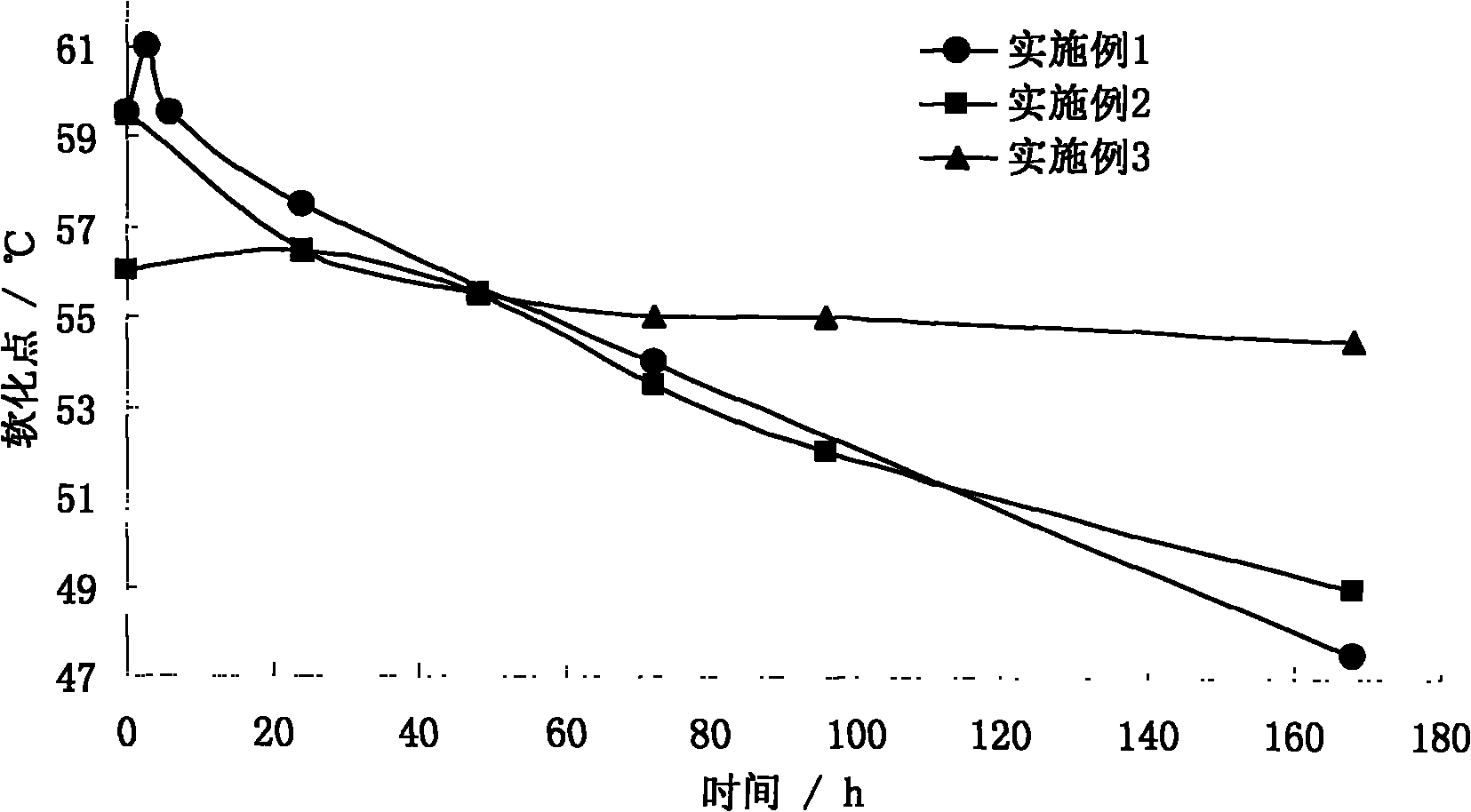

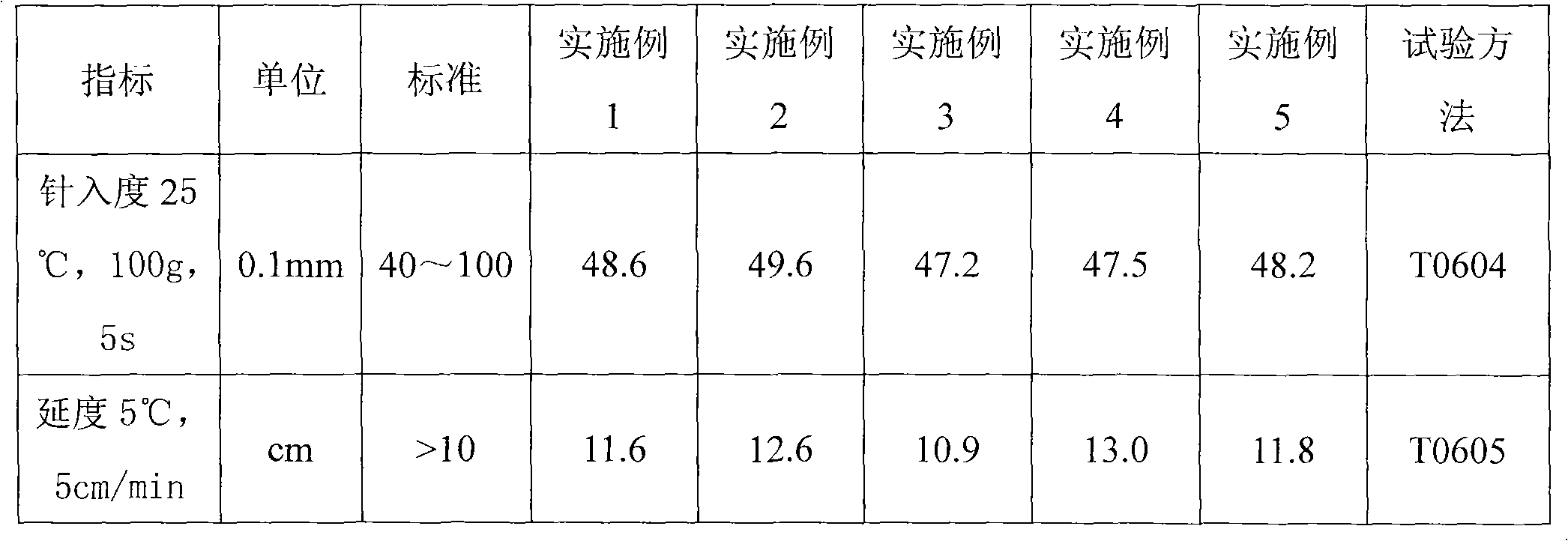

Embodiment 1

[0026] Taking the production of about 10 tons of rubber powder modified asphalt products of the present invention as an example, the asphalt in the formula is No. 90 heavy traffic road petroleum asphalt produced by Liaohe Petrochemical, with a penetration of 90; the rubber powder is 30 mesh.

[0027] Components and weight percentages contained in the formula are:

[0028] Asphalt 8t

[0029] Rubber powder 2t

[0030] Take Liaohe No. 90 petroleum asphalt, heat it to 180°C in the reaction kettle, then slowly add 30 mesh waste tire rubber powder, stir at low speed (300-1000 rpm) for 20 minutes, raise the temperature to 190°C, and then use high-speed shear The cutting machine shears and grinds once to obtain the product of the present invention.

Embodiment 2

[0032] Taking the production of about 10 tons of rubber powder modified asphalt products of the present invention as an example, the asphalt in the formula is No. 90 heavy traffic road petroleum asphalt produced by Liaohe Petrochemical, and the penetration is 90; the rubber powder is 30 mesh; 420 heat setting motor oil produced by Tunghsu Chemical Factory.

[0033] Components and weight percentages contained in the formula are:

[0034] Asphalt 8t

[0035] Rubber powder 2t

[0036] Activator 4kg

[0037] Take Liaohe No. 90 petroleum asphalt, heat it to 180°C in the reaction kettle, then slowly add 30 mesh waste tire rubber powder in sequence, stir the activator at a low speed (300-1500 rpm) for 20 minutes, raise the temperature to 190°C, and then Cut and grind once with a high-speed shearing machine to obtain the product of the present invention.

Embodiment 3

[0039] Taking the production of about 10 tons of rubber powder modified asphalt products of the present invention as an example, the asphalt in the formula is No. 90 heavy traffic road petroleum asphalt produced by Liaohe Petrochemical, with a penetration of 90; rubber powder is 30 mesh; the activator is the same as in Example 2.

[0040] Components and weight percentages contained in the formula are:

[0041] Asphalt 8t

[0042] Rubber powder 2t

[0043] Activator 4kg

[0044] DTDM 6kg

[0045]Take Liaohe No. 90 petroleum asphalt and heat it to 180°C in the reaction kettle, then slowly add 20 mesh waste tire rubber powder and activator, stir at low speed (300-1500 rpm) for 15 minutes, raise the temperature to 190°C, and then use high-speed The shearing machine is ground once, then the anti-reversion agent is added, and the product is pumped into the storage tank to obtain the product of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com