Steel box girder bridge deck pavement layer with high stability and high vibration resistance

A high-stability, bridge deck pavement technology, which is applied in the field of cohesive pavement paved on site, bridges, bridge construction, etc., can solve the problem of reduced bonding strength between the waterproof adhesive layer and the bridge deck, reduced waterproofing effect, and pollution and other problems, to achieve the effect of good elasticity, enhanced bond strength, and avoid shear damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

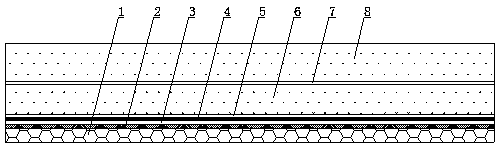

[0018] The present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 As shown, a steel box girder bridge deck pavement layer with high stability and high anti-vibration performance includes a steel plate 1, a waterproof adhesive layer 2, a modified epoxy resin structural adhesive layer 3, Polyester filament geotextile bonding layer 4, the first high-viscosity modified asphalt bonding layer 5, the first high-viscosity modified polyester fiber-doped asphalt mastic macadam mixture (SMA) layer 6, the second high-viscosity Modified asphalt bonding layer 7, second high viscosity modified polyester fiber mixed asphalt mastic macadam mixture (SMA) layer 8.

[0019] The present invention is achieved like this:

[0020] 1. Bridge deck steel plate treatment

[0021] During the construction, the surface of the bridge deck steel plate is required to be flat, clean, and pollution-free. The steel plate is sandblasted and derusted to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com