Tray conveying assembly line

A pallet conveying and assembly line technology, applied in the field of assembly line, can solve the problems of increasing the load of the assembly line, damage to the pallet, affecting the transportation of the assembly line, etc., and achieve the effect of ensuring balance, preventing tilt, and ensuring the stability of conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

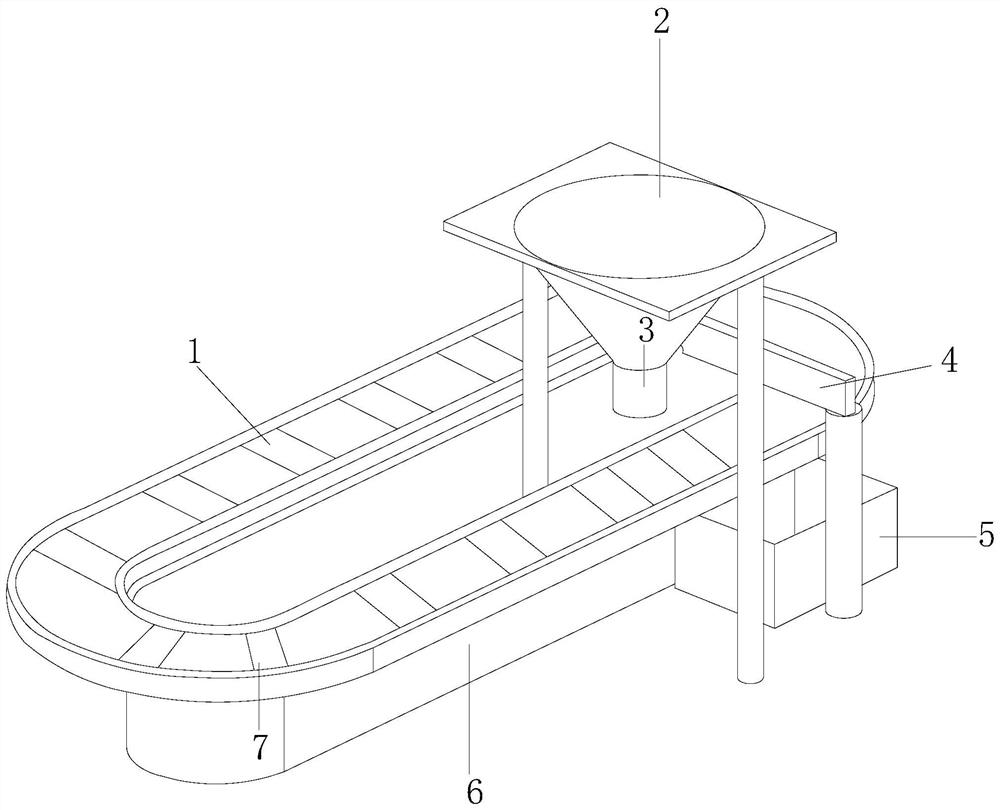

[0031] see figure 1 , the present invention provides a technical solution: a pallet conveying line, the structure of which includes a conveyor belt 1, a material tray 2, a discharge port 3, a height limit baffle 4, a placement frame 5, a main body 6, and an adjustment device 7. The conveyor belt 1 is integrated with the main body 6, a placement frame 5 is installed on one side of the main body 6, a height-limiting baffle 4 connected thereto is provided on the conveyor belt 1, and the conveyor belt 1 and the adjustment device 7 are movable. Together, the conveyor belt 1 is provided with a discharge port 3, and the discharge port 3 is fixedly connected with the tray 2.

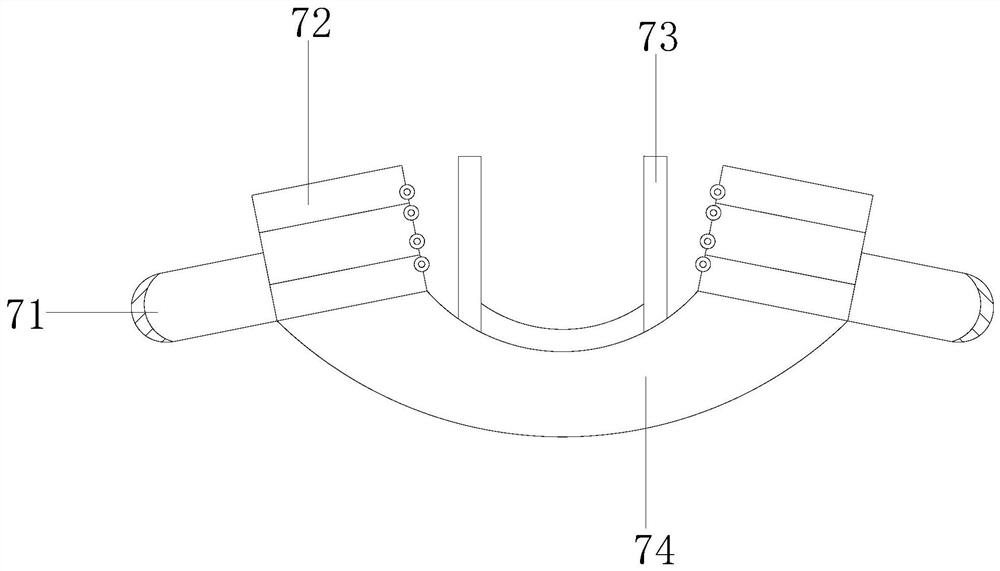

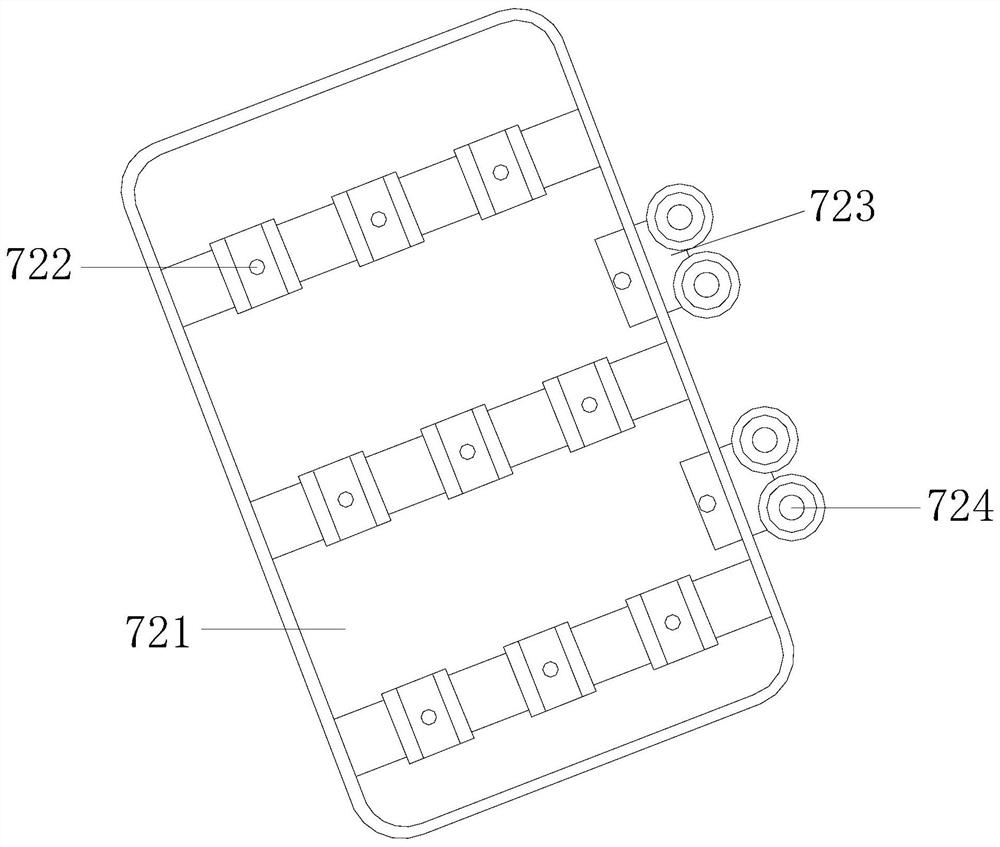

[0032] see figure 2 , the correcting device 7 includes a moving slide 71, a resisting piece 72, a holding seat 73, and a protective bracket 74. There are two moving slides 71, and the two moving slides 71 are symmetrically installed on two resisting On one side of the member 72, a protective bracket 74 conne...

Embodiment 2

[0042] see figure 1 , the present invention provides a technical solution: a pallet conveying line, the structure of which includes a conveyor belt 1, a material tray 2, a discharge port 3, a height limit baffle 4, a placement frame 5, a main body 6, and an adjustment device 7. The conveyor belt 1 is integrated with the main body 6, a placement frame 5 is installed on one side of the main body 6, a height-limiting baffle 4 connected thereto is provided on the conveyor belt 1, and the conveyor belt 1 and the adjustment device 7 are movable. Together, the conveyor belt 1 is provided with a discharge port 3, and the discharge port 3 is fixedly connected with the tray 2.

[0043] see figure 2 , the correcting device 7 includes a moving slide 71, a resisting piece 72, a holding seat 73, and a protective bracket 74. There are two moving slides 71, and the two moving slides 71 are symmetrically installed on two resisting On one side of the member 72, a protective bracket 74 conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com