Belt conveyor for rice processing

A belt conveyor, rice processing technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of inconvenience, affect the quality of rice, mixed impurities, etc., to improve work efficiency, ensure processing quality, reduce The effect of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

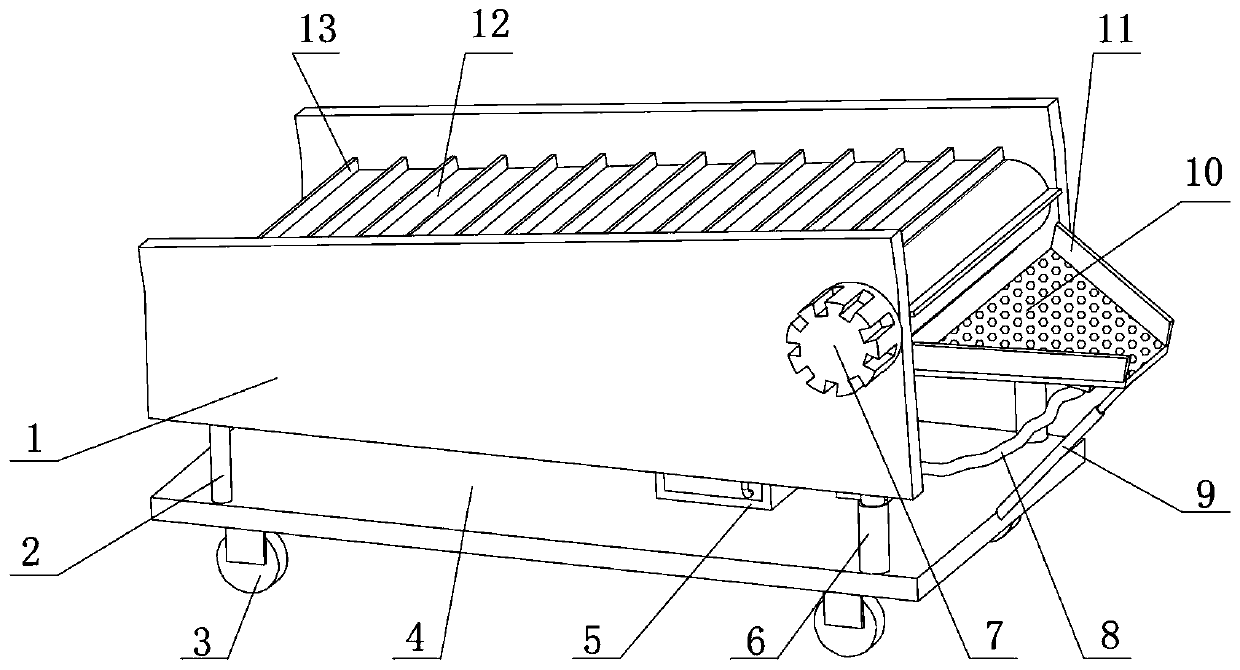

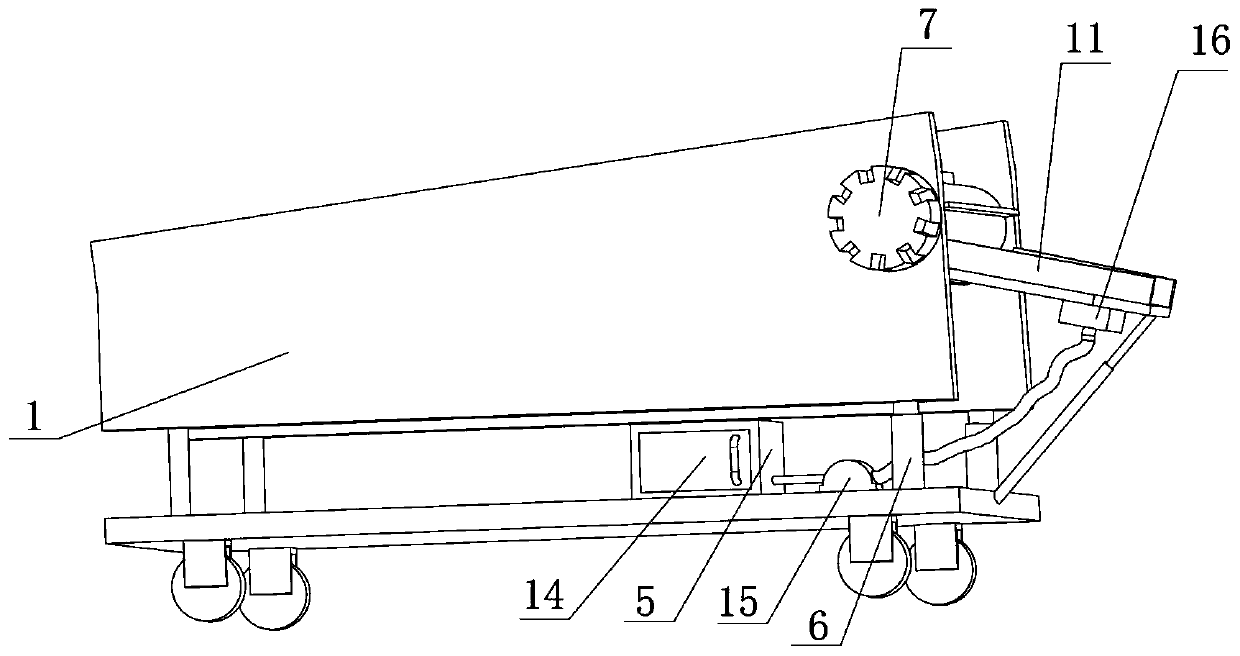

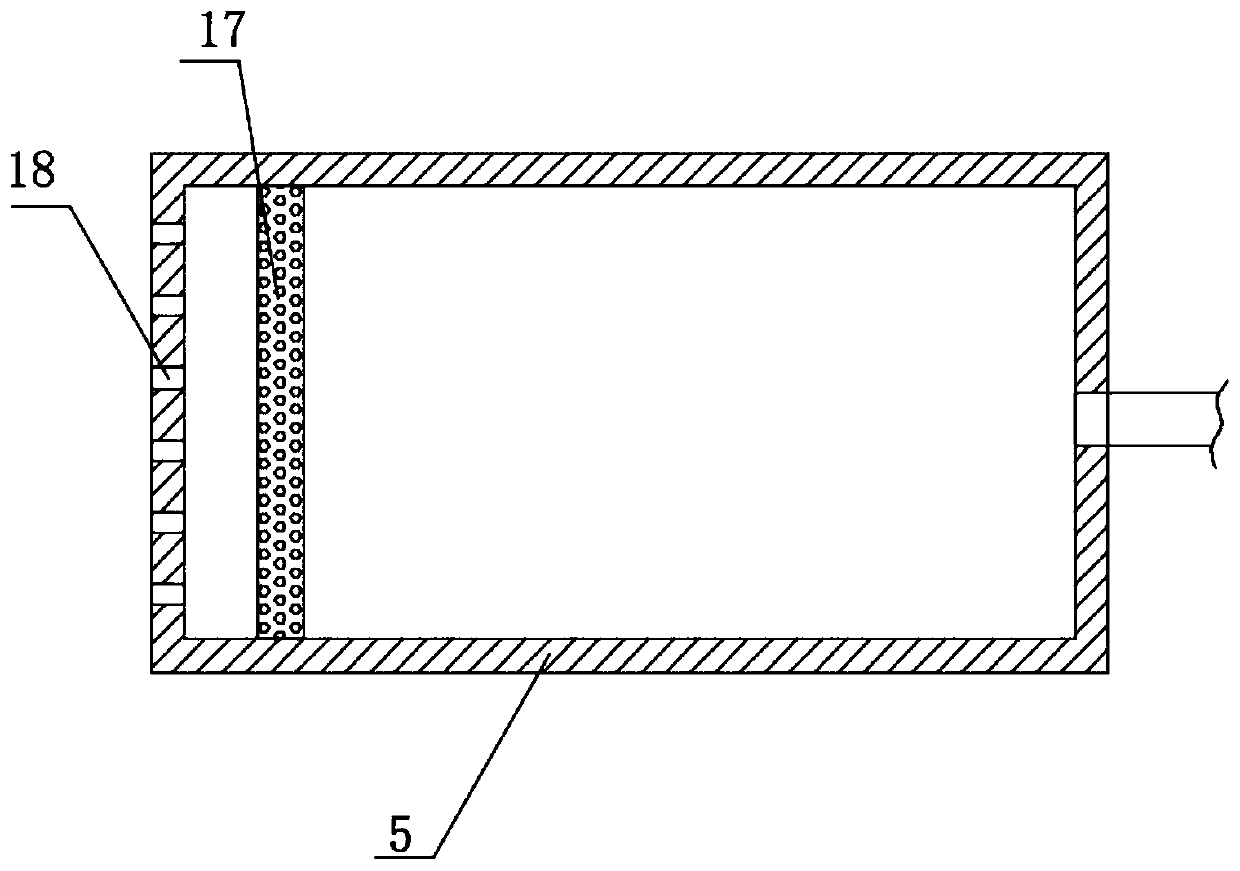

[0028] A belt conveyor for rice processing, such as Figure 1-3 As shown, it includes two mounting plates 1, the opposite ends of the two mounting plates 1 are rotatably connected with rotating shafts on both sides of the outer walls, and the outer walls of the two rotating shafts are sleeved with the same conveyor belt 12, and the outer walls of the outer walls of the conveyor belt 12 are installed There are stoppers 13 equidistantly distributed, and the same blanking screen 10 is connected to the outer wall of the opposite end of the two mounting plates 1 by rotation, and both ends of the top outer wall of the blanking screen 10 are equipped with partitions 11. An air inlet bucket 16 is installed on the outer wall of the bottom of the screen plate 10, and an air inlet pipe 8 is installed on the outer wall of the bottom of the air inlet bucket 16, and a stepping motor 7 is installed on one side of the outer wall at one end of one of the mounting plates 1, and the output shaft ...

Embodiment 2

[0032] A belt conveyor for rice processing, such as Figure 1-4 As shown, foot-operated hydraulic rods 19 are installed at both ends of the outer walls on both sides of the base plate 4 , and rubber seats 20 are installed on the outer walls at the bottom of the foot-operated hydraulic rods 19 .

[0033] When this embodiment is in use, the conveyor can be stably fixed on the working site by being provided with a foot-operated hydraulic rod 19 and a rubber seat 20, so as to avoid the movement of the belt conveyor during work, ensure the quality of rice conveying, and facilitate work personnel use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com