High-temperature-resisting conveyer belt

A conveyor belt and high-temperature-resistant technology, which is applied in the fields of high-temperature sintered ore, high-temperature-resistant conveyor belt, and cement clinker, can solve the problems of low-efficiency high-temperature material transportation, achieve excellent wear resistance, excellent heat resistance, The effect of delaying cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

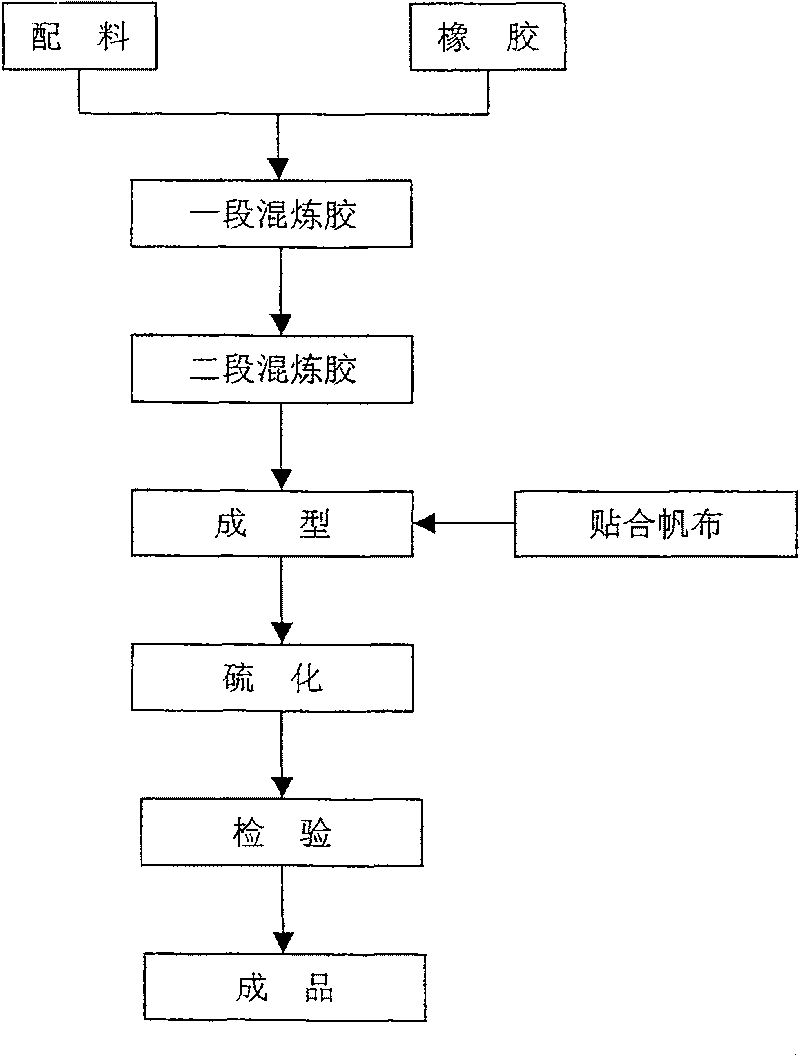

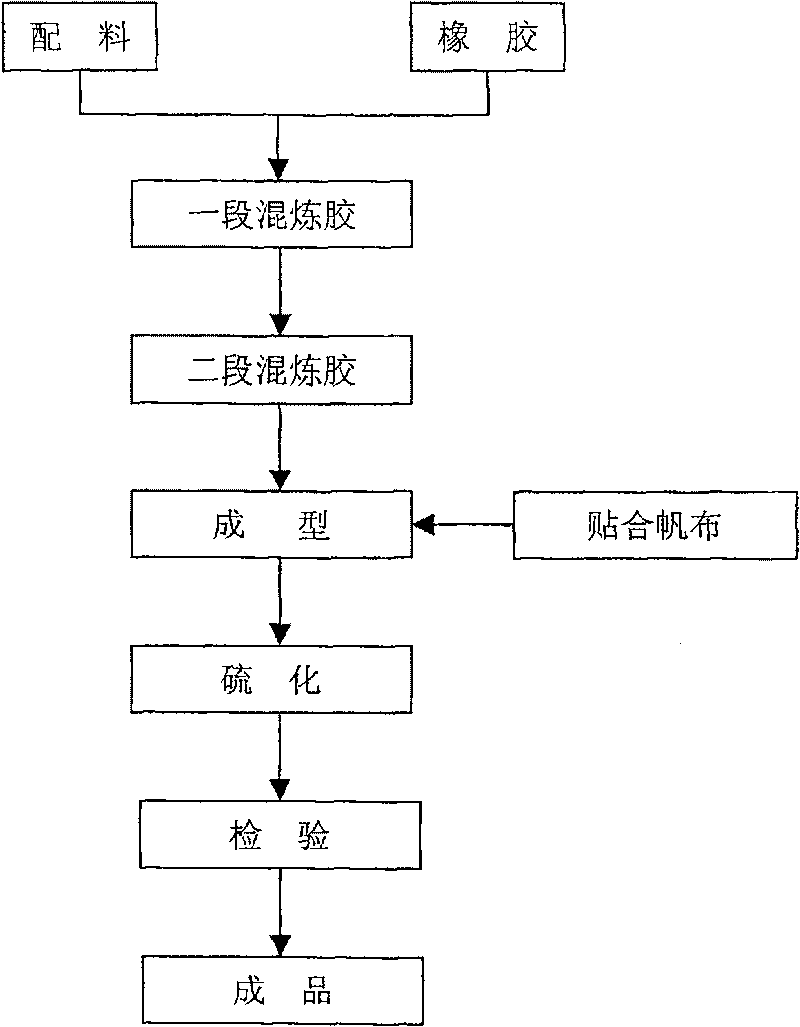

[0027] Embodiment 1: The production process of the high temperature resistant conveyor belt of the present invention is as follows:

[0028] The high-temperature-resistant conveyor belt of the present invention adopts a canvas with a core tensile body between the covering rubber of the working surface and the covering rubber of the non-working surface, and they are firmly combined into a whole through molding and vulcanization processes.

[0029] Its composition and proportioning of the working face covering glue described in the embodiments of the present invention are in parts:

[0030] 1. Rubber mixing process:

[0031] a. One stage mixing process:

[0032] Add 100 parts of binary ethylene propylene rubber to the internal mixer for pre-compression mixing, mixing time: 28-32 seconds; add fine materials: thermal conductive agent, 10 parts of zinc oxide, anti-aging agent 1: RD, scientific name: 2,2 , 4-trimethyl-1,2-dihydroquinoline polymer: 2 parts, anti-aging agent 2: 1010...

Embodiment 2

[0045] Its composition and proportioning of the working face covering glue described in the embodiments of the present invention are in parts:

[0046] The present invention gets binary ethylene propylene glue: 90 parts;

[0047] EPDM rubber: 10 parts;

[0048] Cross-linking agent, DCP-40: 7 parts;

[0049] Auxiliary cross-linking agent, TAIC: 2.0 parts;

[0050] Heat conduction agent zinc oxide: 15 parts;

[0051] Reinforcing agent 1, N330: 30 parts;

[0052] Reinforcing agent 2, N550: 30 parts;

[0053] Softener 1, paraffin oil, SUNPAR2280: 30 parts;

[0054] Softener 2, liquid ethylene propylene rubber: 10 parts;

[0055] Aramid staple fiber: 6.5 parts;

[0056] Antiaging agent 1, RD: 2 parts;

[0057] Antiager 2, 1010: 2 parts.

[0058] The above formula is made into the working surface covering rubber according to the process steps in the first implementation, and a tensile canvas with a core is provided between the working surface covering rubber and the non-wor...

Embodiment 3

[0060] Its composition and proportioning of the working face covering glue described in the embodiments of the present invention are in parts:

[0061] Binary ethylene propylene rubber: 80 parts;

[0062] EPDM rubber: 20 parts;

[0063] Cross-linking agent, DCP-40: 6.6 parts;

[0064] Auxiliary cross-linking agent, TAIC: 2.0 parts;

[0065] Heat conduction agent zinc oxide: 22 parts;

[0066] Reinforcing agent 1, N330: 35 parts;

[0067] Reinforcing agent 2, N550: 25 parts;

[0068] Softener 1, SUNPAR2280: 20 parts;

[0069] Softener 2, liquid ethylene propylene rubber: 16 parts;

[0070] Aramid staple fiber: 8 parts;

[0071] Antiaging agent 1, RD: 2 parts;

[0072] Antiager 2, 1010: 2 parts.

[0073] The above formula is made into the working surface covering rubber according to the process steps in the first implementation, and a tensile canvas with a core is provided between the working surface covering rubber and the non-working surface covering rubber, and they ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com