Arrangement mechanism for corn husker

A technology of peeling and smoothing, which is applied to agricultural machinery and implements, conveyor objects, threshing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

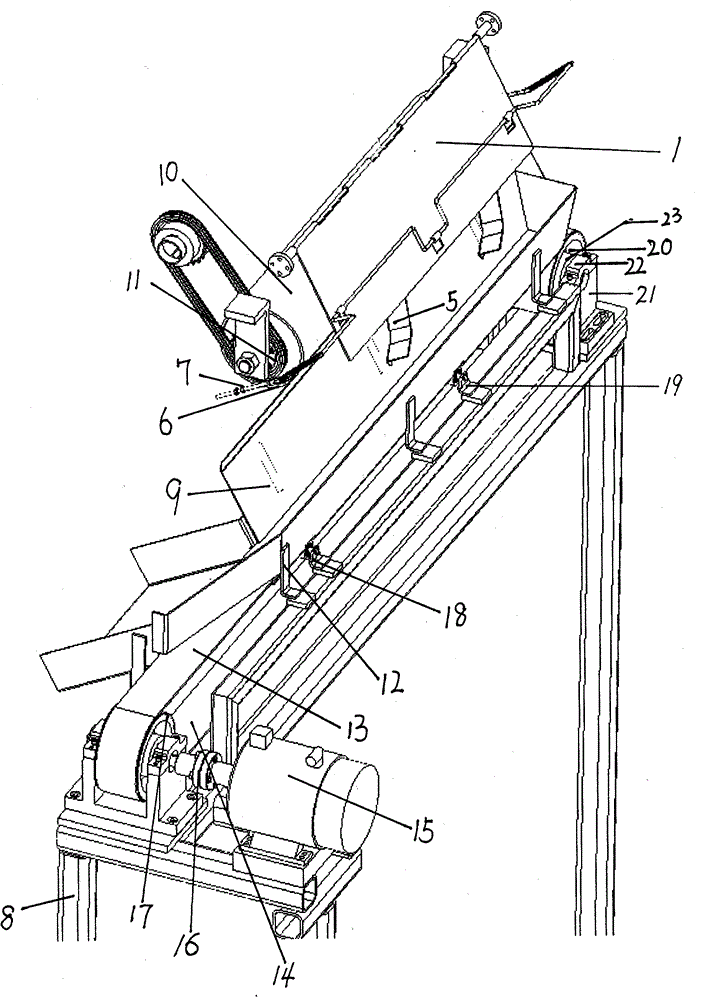

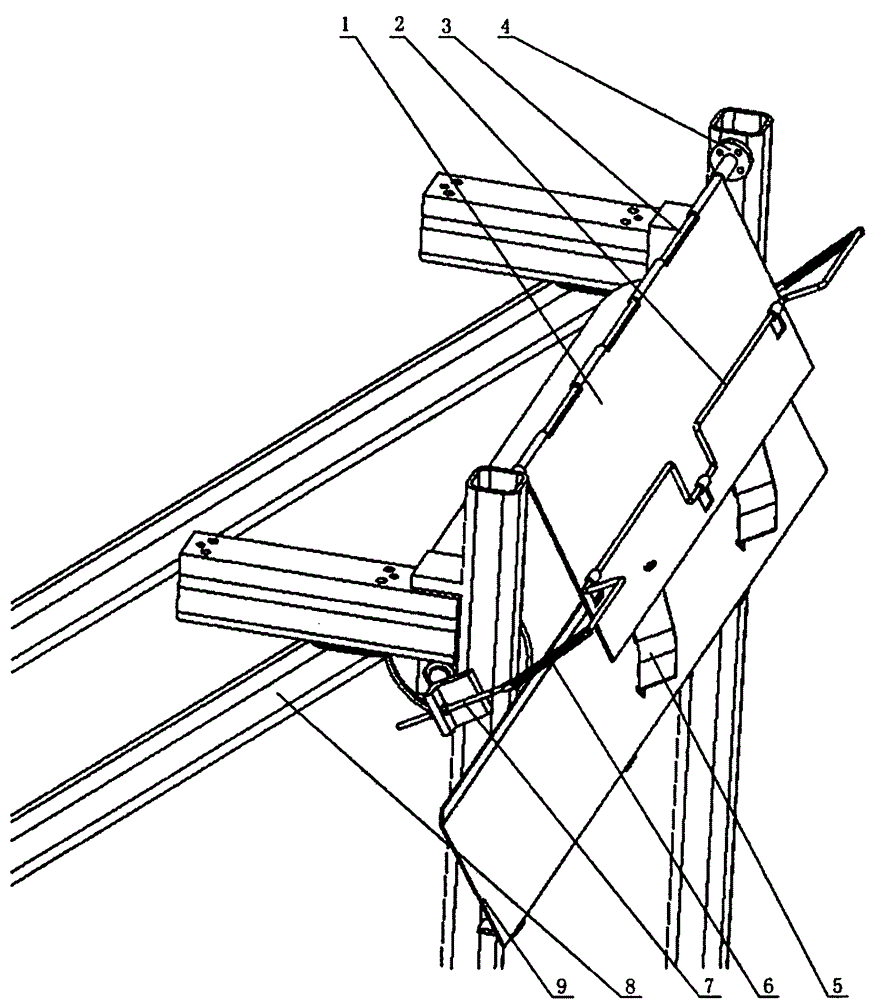

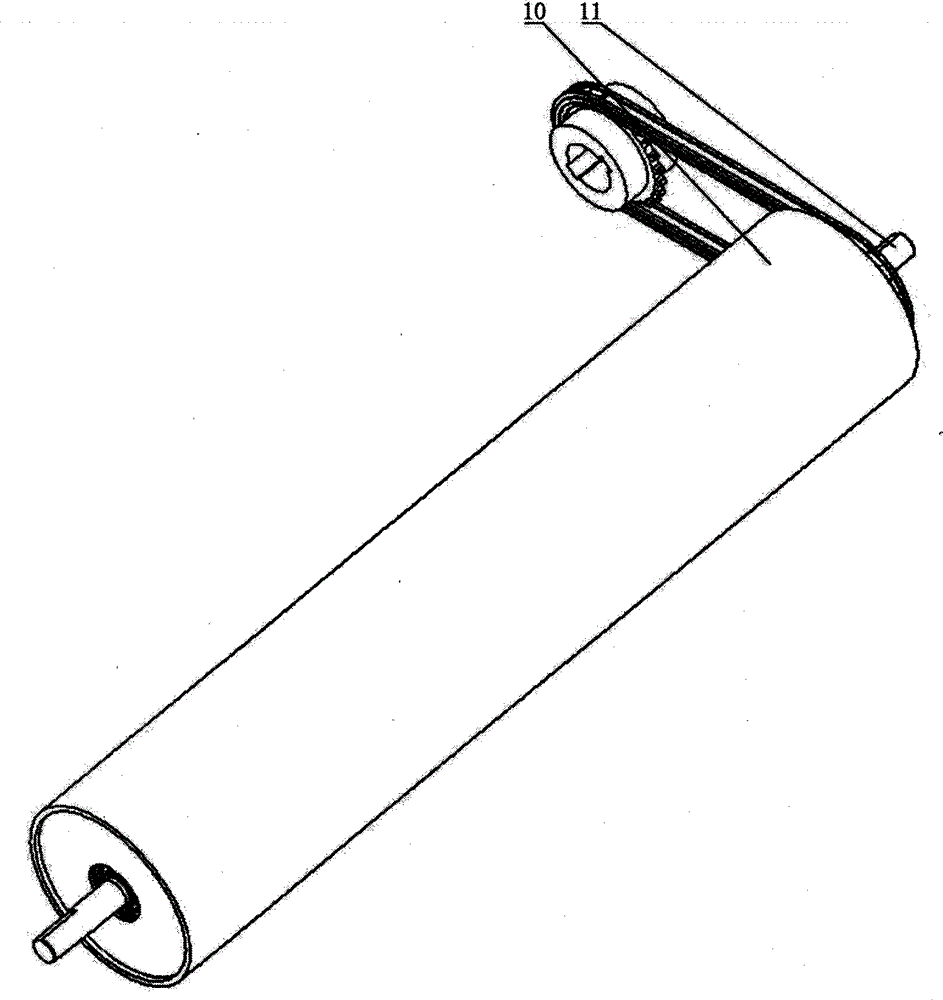

[0012] The specific implementation will be further described below in conjunction with the accompanying drawings of the description: figure 1 The overall structure of the feeding mechanism of the present invention is shown. The specific implementation is as attached figure 1 As shown, sheet metal curling large baffle 1, spring shaft 2, baffle shaft 3, rotating sleeve 4, guide plate 5, tension spring 6, bolt hook 7, frame 8, baffle 9, booster cylinder 10 , booster cylinder shaft 11, feeding bracket 12, feeding board 13, conveyor belt 14, motor 15, coupling 16, driving pulley 17, idler 18, idler bracket 19, driven pulley 20, pulley Seat 21, belt wheel seat cover 22, jump ring 23. Mechanism details sequence number 1---9 of the present invention is referring to ( figure 2 ), 10, 11 see ( image 3 ), 12---20 see ( Figure 4 ), 21----23 see ( Figure 4 ).

[0013] Among them, the corn falls through the conveyor belt, the corn falls on the sorting plate 5 through the hopper 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com