Automatic pipe arrangement system for land drill rig racking platform

A two-story platform and drilling rig technology, applied in the direction of drill pipe, drill pipe, casing, etc., can solve the problems of poor safety in the working environment, labor-intensive, low drilling efficiency, etc., achieve high stability and automation, and reduce labor intensity , The effect of improving drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the accompanying drawings.

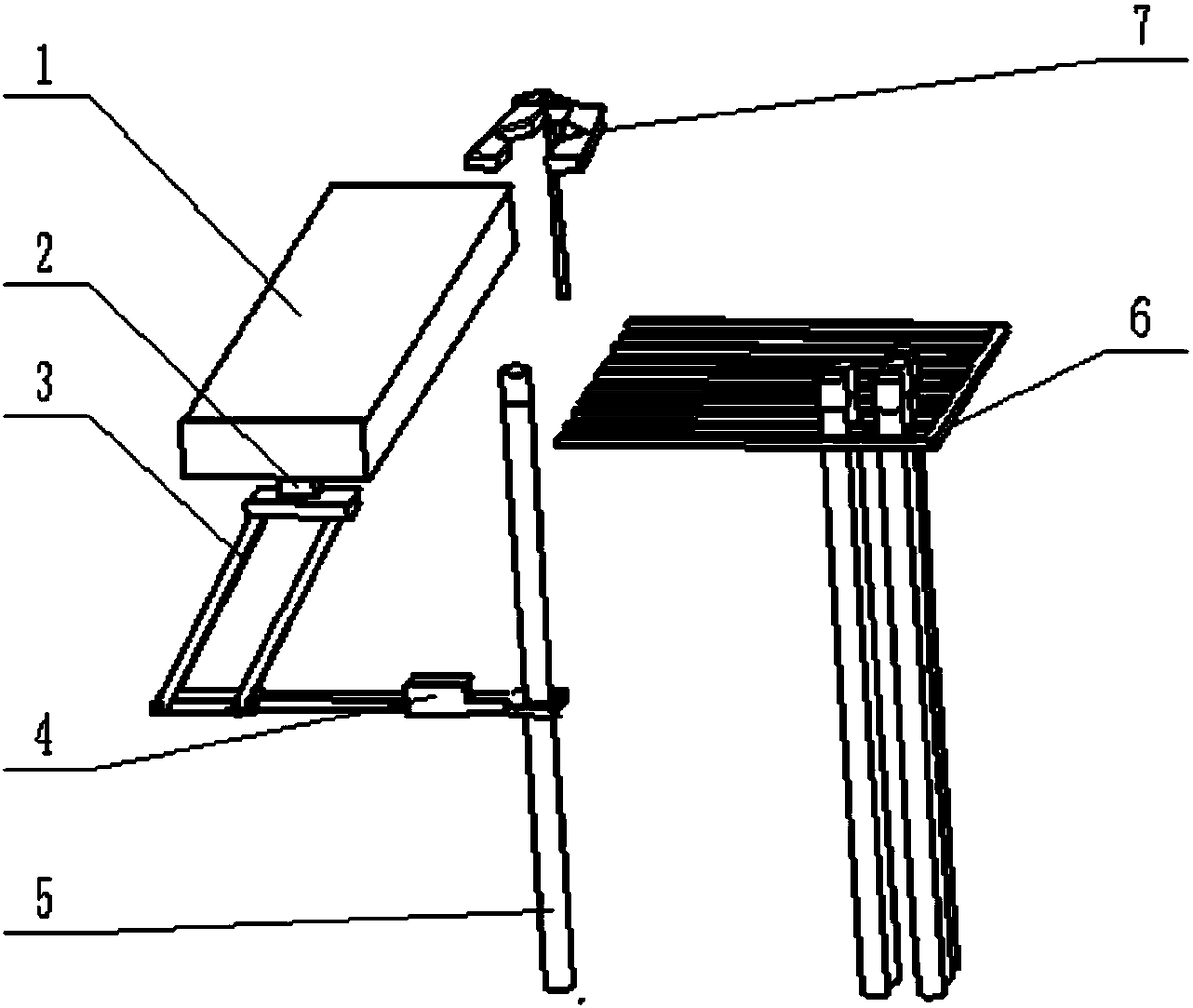

[0027] Such as figure 1 As shown: the automatic piping system of the two-story platform includes a translation mechanism 1, a rotation mechanism 2, a parallelogram mechanism 3 and a clamping mechanism 4. The parallel mechanism 1 is located above the rotation mechanism 2, and the rotation mechanism 2 and the guide rail 8 inside the parallel mechanism 1 The installed slide block 9 is connected by bolts; the shaft seat 17 of the rotating mechanism 3 is connected with the fixed upper plate 19 of the parallelogram mechanism 3; the lower connecting plate 25 on the parallelogram mechanism 3 is connected with the clamping mechanism 4.

[0028] The translation mechanism 1 is composed of a guide rail 8 and a slider 9 .

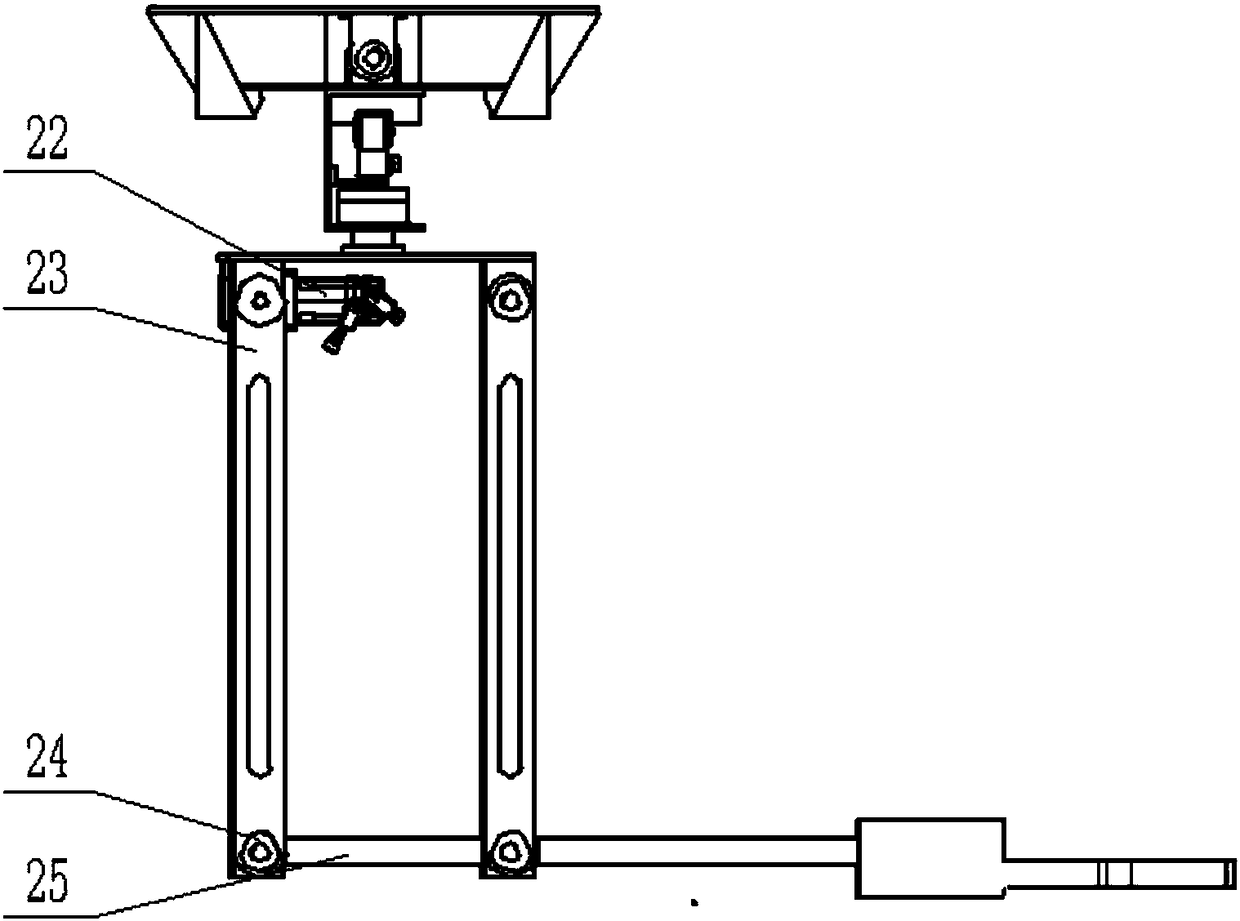

[0029] Such as figure 2 As shown: the rotating mechanism 2 is composed of a fixed casing 15, an explosion-proof motor 11, a reducer 10, a rotating shaft 17, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com