Repair method of composite main paddle with hinge moment variance

A hinge moment, composite material technology, applied in aircraft maintenance, aircraft parts, ground installations, etc., can solve the problem that the hinge value of the main blade does not meet the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

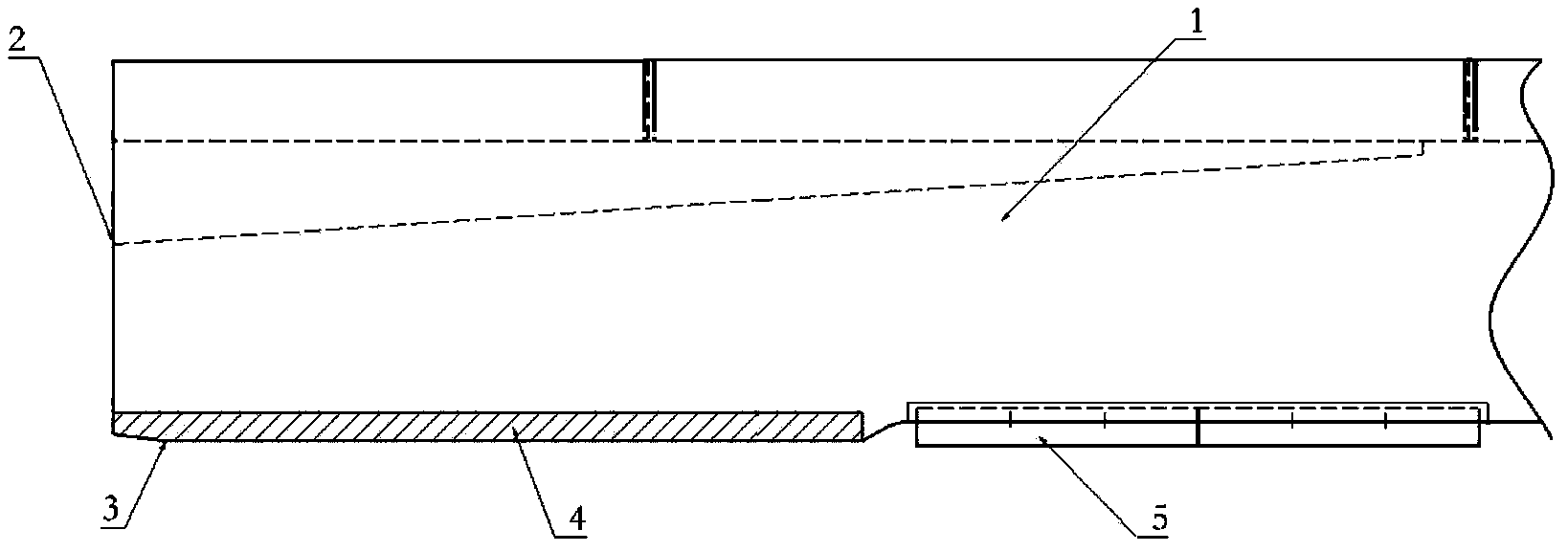

[0035] Taking the repair of a composite blade with a length of 5250 mm and a chord of 405 mm as an example, the present invention will be described in further detail below.

[0036] A repair method of composite material main blade hinge torque is out of tolerance. The specific steps of this method are as follows:

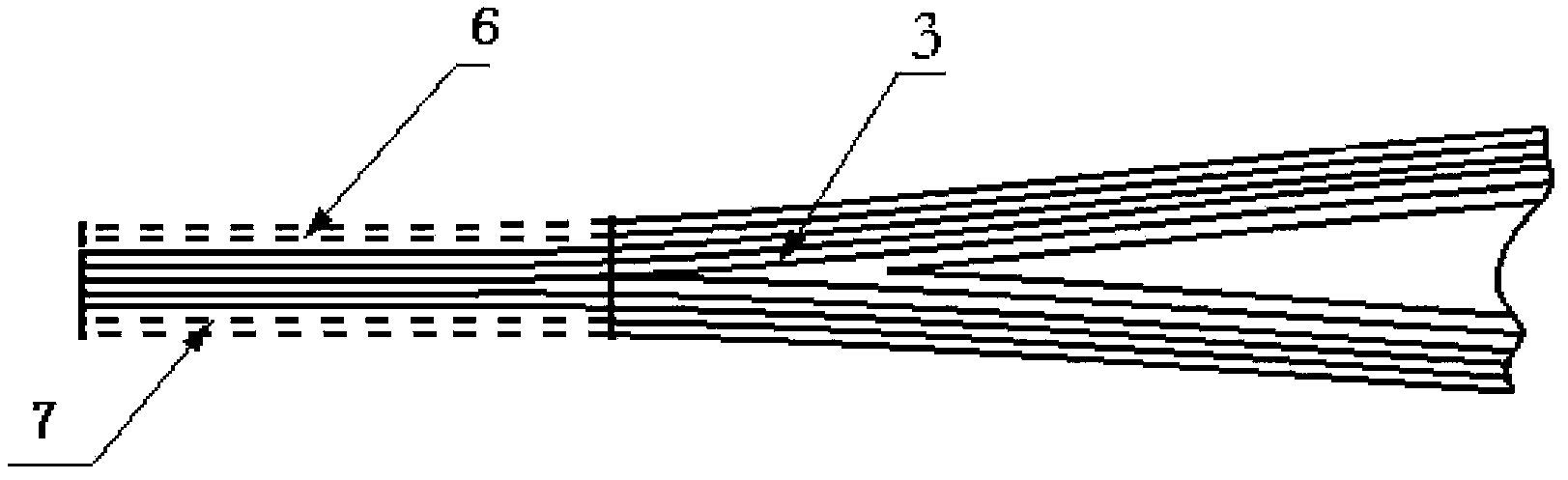

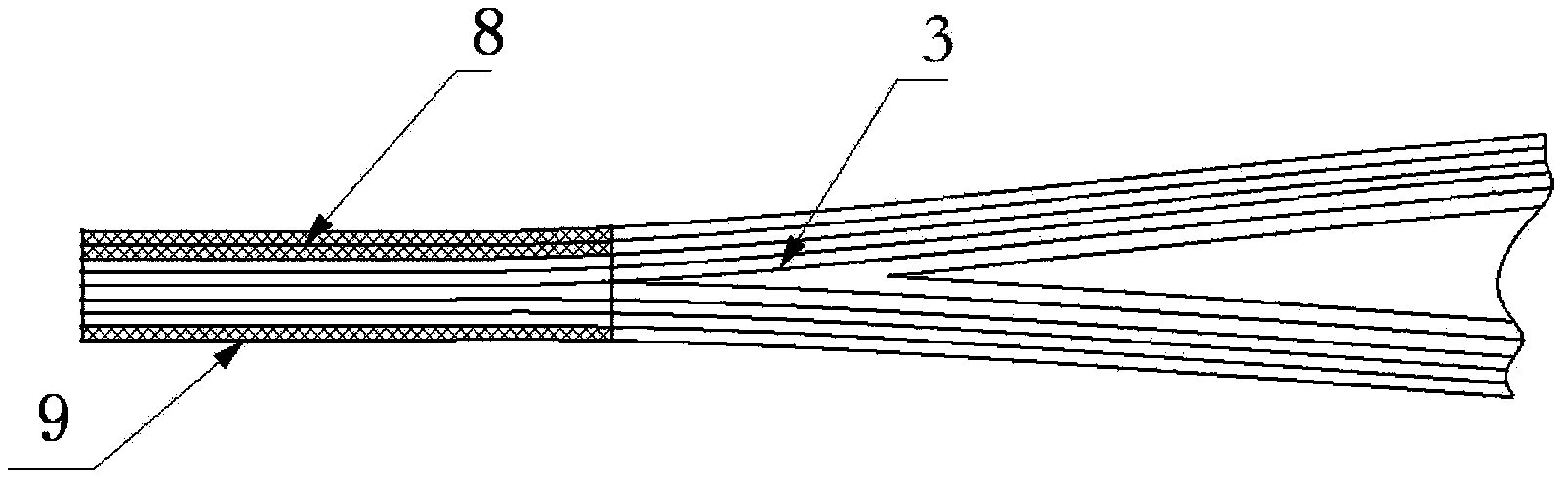

[0037] The first step is to reasonably define the repair area of the main blade according to the over-tolerance of the blade hinge torque: (1) When the angle of all the adjustment blades of the main blade reaches the positive limit +6°, the blade tip The rear edge is polished, and the glass cloth on the rear edge of the upper wing surface of the wing tip, 2 layers of carbon cloth and 1 layer of glass cloth on the rear edge of the lower wing surface are peeled off. The peeling width is 30mm from the rear edge to the front edge. The length of the blade is 700mm from the tip of the wing to the root of the wing, and the thickness of the trailing edge of the stripped part i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com