Mooney viscometer

A technology of Mooney viscosity and mold body, which is applied in the direction of instruments, scientific instruments, flow characteristics, etc., can solve problems such as rubber melting, and achieve the effect of reducing frictional resistance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

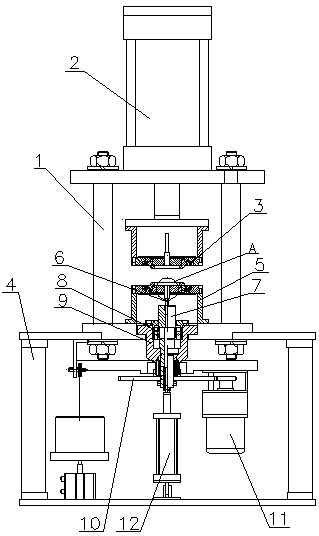

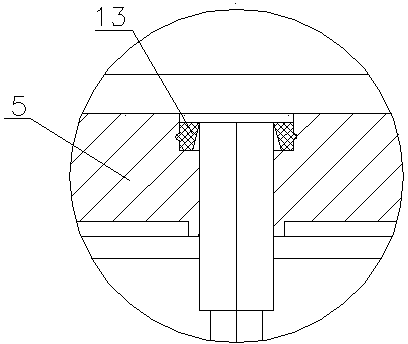

[0011] A Mooney viscometer, comprising a lifting cylinder 2 installed on the upper end of a frame 1, the piston rod of the lifting cylinder 2 is connected with the upper mold body 3 in the frame 1, the lower end of the frame 1 is provided with a lower mold frame 4, The upper end of the lower mold frame 4 is provided with a lower mold body 5 corresponding to the upper mold body 3, and the inner hole of the lower mold body 5 is provided with a rotor 6, and the rotor 6 is covered with a main shaft 7, and the main shaft 7 is installed on the upper end of the lower mold base 4 through a bearing 8. In the bearing seat 9, the lower end of the main shaft 7 is provided with a driving gear 10 located in the lower mold frame 4, and the lower mold frame 4 is provided with a motor 11, the output end of the motor 11 is connected with the driving gear 10, and the lower end of the main shaft 7 is provided with a cylinder 12 for installation. On the lower mold frame 4, the piston rod of the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com