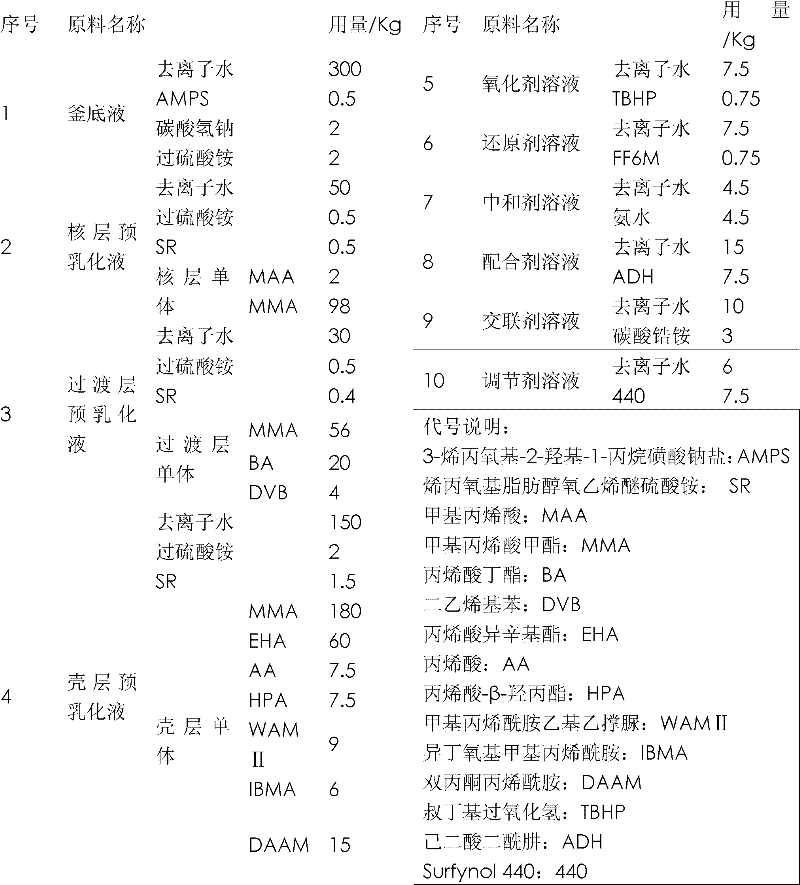

Single-component water-based adhesive for evaporative cooling wet curtain and preparation method thereof

A single-component, evaporative technology, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesive types, etc., can solve the problem of long-term high and low temperature resistance of wet curtains and slow release of free formaldehyde , bring out harmful substances and other problems, achieve excellent wetting and leveling performance, ensure adhesion and water resistance, and improve wet adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 synthetic method:

[0035] According to the formula composition and consumption of the embodiment 1 listed in table 2, the single-component water-based adhesive for evaporative cooling wet curtain is synthesized as follows:

[0036] (1) In formula No. 1, deionized water, AMPS, sodium bicarbonate and ammonium persulfate are stirred and mixed evenly to form the bottom liquid, and then added to the polymerization reactor;

[0037] Embodiment 1 raw material formula is shown in Table 2:

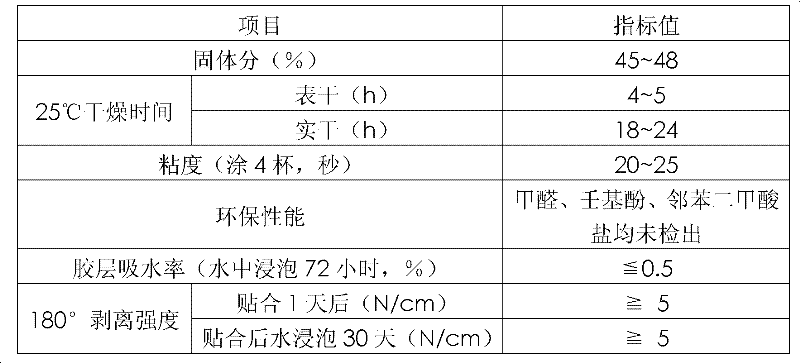

[0038] Table 2. The evaporative cooling wet curtain of embodiment 1 uses single-component water-based adhesive raw material formula

[0039]

[0040] (2) Add deionized water, ammonium persulfate and SR in the formula number 2 to the first pre-emulsification tank, stir slowly and disperse evenly, then add AA and MMA, stir quickly and disperse evenly to form a stable core layer pre-emulsion; In formula number 3, deionized water, ammonium persulfate and SR were added to the s...

Embodiment 2

[0045] Embodiment 2 synthetic method:

[0046] According to the formula composition and consumption of Example 2 listed in Table 3, the single-component water-based adhesive for evaporative cooling wet curtains is synthesized as follows:

[0047] (1) In formula No. 1, deionized water, AMPS, sodium bicarbonate and ammonium persulfate are stirred and mixed evenly to form the bottom liquid, and then added to the polymerization reactor;

[0048] (2) Add deionized water, ammonium persulfate and SR in the formula No. 2 to the first pre-emulsification tank and stir slowly to disperse evenly, then add MAA and MMA, stir quickly and disperse evenly to form a stable core layer pre-emulsion; In formula number 3, deionized water, ammonium persulfate and SR were added to the second pre-emulsification tank and stirred slowly to disperse evenly, then MMA, BA and DVB were added, stirred quickly and dispersed evenly to form a stable transition layer pre-emulsion; In formula number 4, add deion...

Embodiment 3

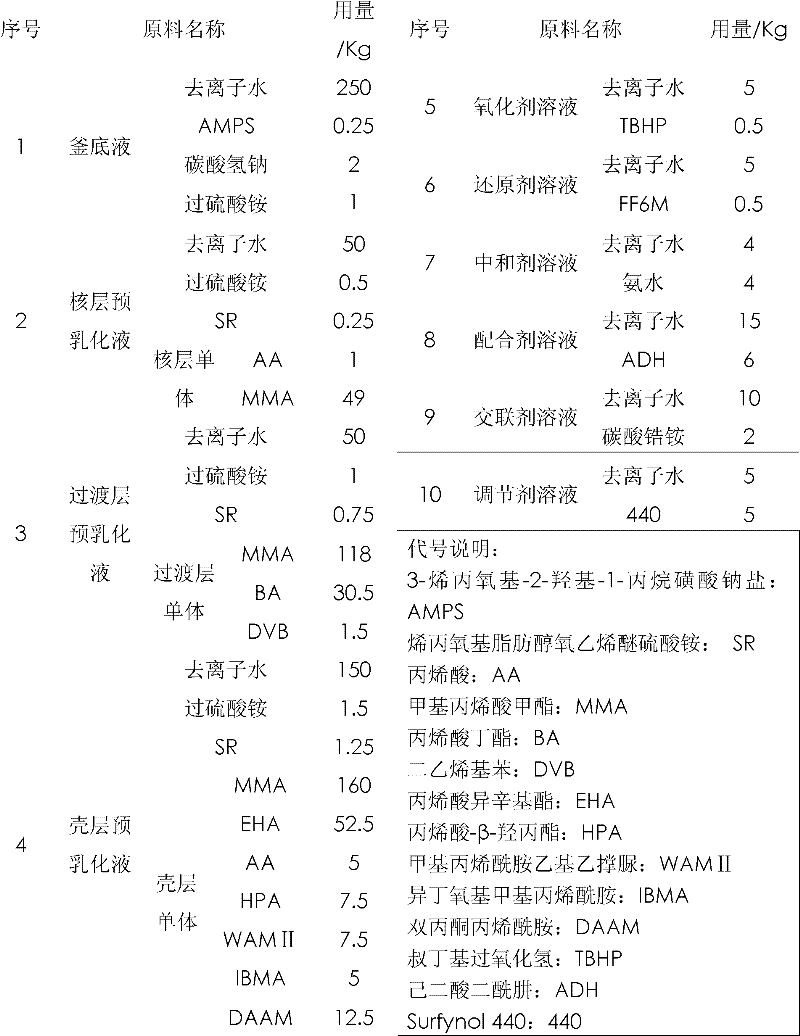

[0056] Embodiment 3 raw material formula is shown in Table 4:

[0057] Table 4. The evaporative cooling wet curtain of embodiment 3 is used single-component water-based adhesive raw material formula

[0058]

[0059] Embodiment 3 synthetic method:

[0060] According to the formula composition and consumption of the embodiment 3 listed in table 4, synthesize the single-component water-based adhesive for the evaporative cooling wet curtain as follows:

[0061] (1) In formula No. 1, deionized water, AMPS, sodium bicarbonate and ammonium persulfate are stirred and mixed evenly to form the bottom liquid, and then added to the polymerization reactor;

[0062] (2) Add deionized water, ammonium persulfate and SR in the formula number 2 to the first pre-emulsification tank, stir slowly and disperse evenly, then add AA and MMA, stir quickly and disperse evenly to form a stable core layer pre-emulsion; Add deionized water, ammonium persulfate and SR into the second pre-emulsificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com