Patents

Literature

77results about How to "Improved wet adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Interpolymer latex of polystyrene and acrylic ester in hud polymerization type, and preparation method

This invention relates to a core-shell polystyrene-acrylate copolymer emulsion, which comprises: emulsifiers 0.2-1.5 wt.%, monomers 45-55 wt.%, initiator 0.1-0.3 wt.%,, pH regulator 0.1-0.2 wt.%, and deionized water as balance. The emulsifiers are two or three of anionic emulsifier, nonionic emulsifier and functional allyloxy hydroxypropyl sulfonate emulsifier. The monomers are soft monomer, hard monomer and functional silane monomer containing epoxy groups and oxy groups. The solid content of the emulsion is 48-52%, the glass transition temperature of the core is 25-35 deg.C, and the glass transition temperature of the shell is (-5)-5 deg.C. The emulsion has such advantages as high wet adhesivness of the coating film and high washing resistance of the coating film.

Owner:CHANGZHOU GUANGHUI CHEM +1

Gold print paste and preparation method thereof

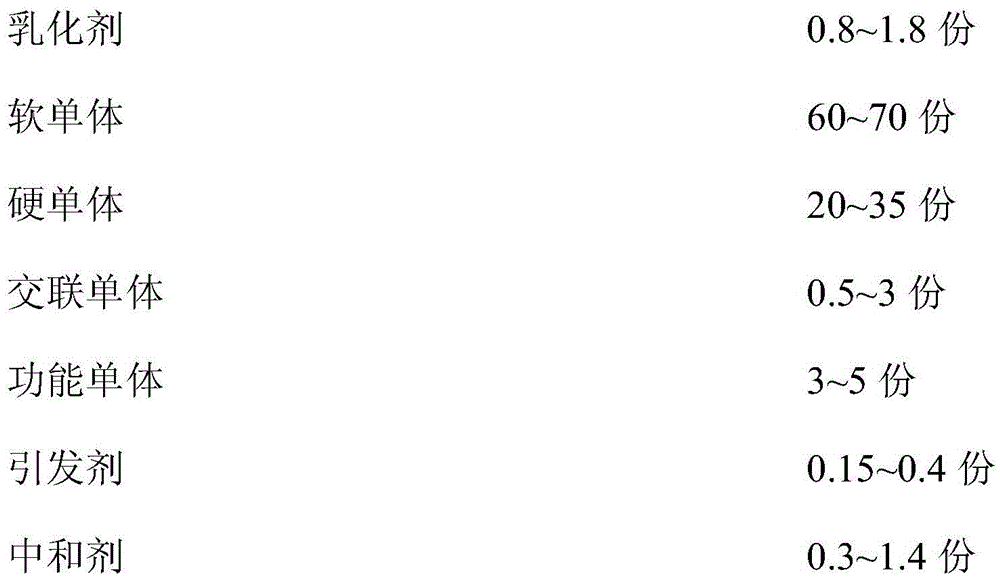

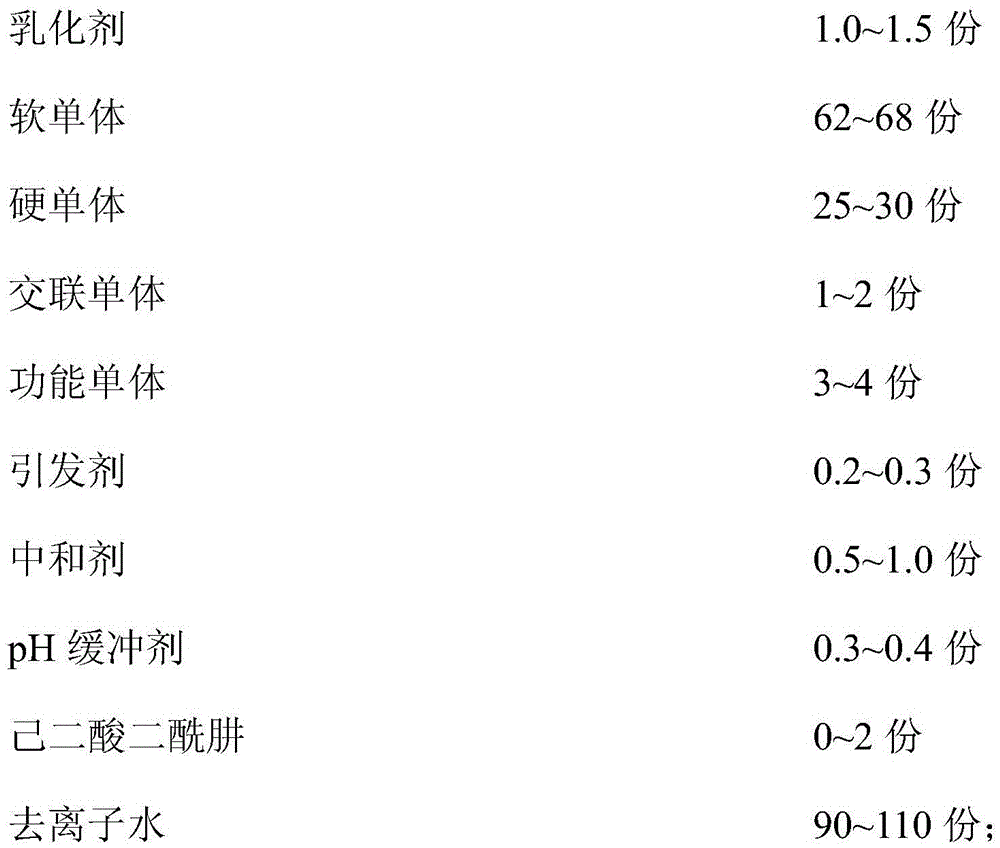

The invention provides gold print paste and a preparation method thereof. The gold print paste is prepared from, by weight, acrylic emulsion, hot melting powder, a curing agent, a thickening agent and a defoaming agent; the acrylic emulsion is mainly prepared from, by weight, 0.8-1.8 parts of emulsifying agent, 60-70 parts of soft monomer, 20-35 parts of hard monomer, 0.5-3 parts of cross-linking monomer, 3-5 parts of functional monomer, 0.15-0.4 part of initiating agent, 0.3-1.4 part of neutralizing agent, 0.3-0.5 part of pH buffering agent, 0-2.4 parts of adipic acid dihydrazide and 88-115 parts of deionized water. The gold print paste can serve as an adhesive between gold print foil and any cloth, the print making process is easy to implement, prints are not tacky, printing temperature is low, printed textile made through the gold print paste has super-high washable performance, achieves a mirror surface effect and is soft in hand feeling, and the gold print paste has good application prospects in the field of textile and paper products.

Owner:DONGGUAN CTL NEW MATERIAL TECH

Water-based rust-proof primer with rust and preparation method thereof

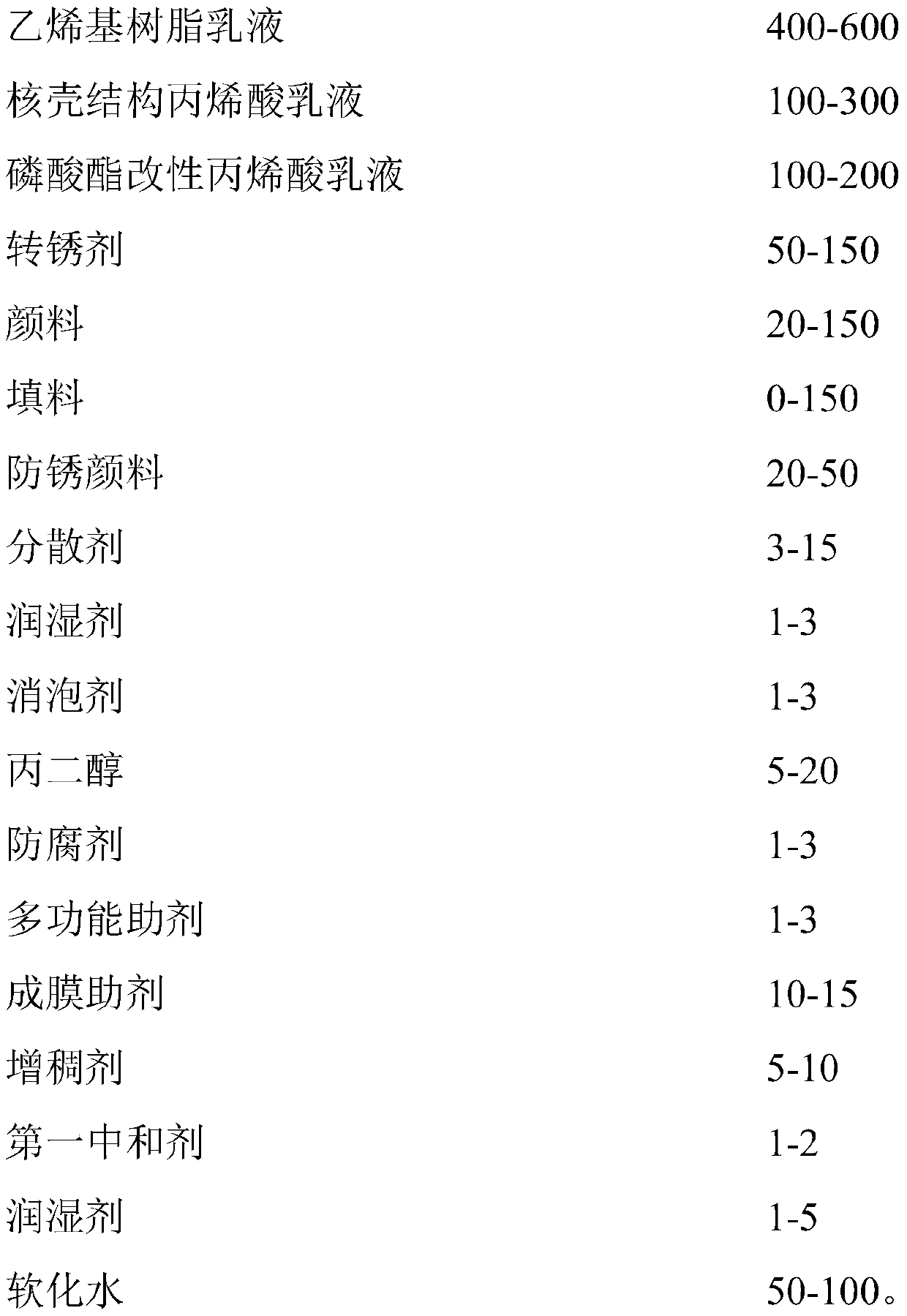

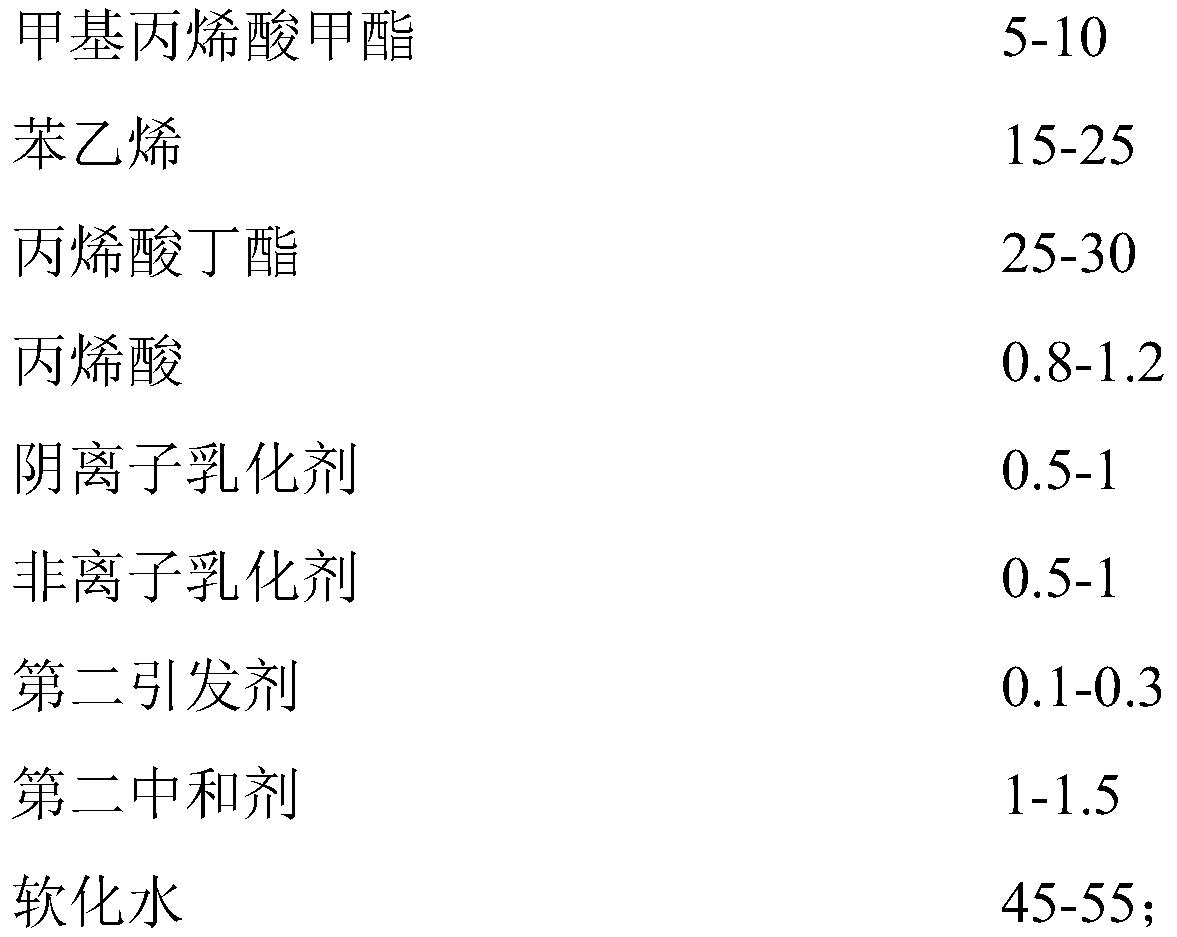

The invention relates to the field of chemical anti-corrosion coatings, particularly to a water-based rust-proof primer with rust and a preparation method thereof. The water-based rust-proof primer with rust uses a vinyl emulsion, a core-shell-structured acrylic emulsion and a phosphate-modified acrylic acid emulsion as base materials. The preparation method comprises the following steps: firstly,selecting the main base material, i.e., the vinyl emulsion; then synthesizing the auxiliary base materials, i.e., the core-shell-structured acrylic resin emulsion and the phosphate-modified acrylic emulsion; and then with the above three emulsions as the base materials, mixing the base materials with a rust conversion agent, an antifreezing agent, a wetting agent, an antifoaming agents and otheradditives to prepare the water-based rust-proof primer with rust. The obtained water-based rust-proof primer with rust is low in VOC content, safe and environment-friendly, convenient to construct, good in compatibility with common anti-corrosion topcoats, good in rust conversion effect, strong in adhesion and long in an antirust period, and has wide application prospects.

Owner:深圳安盾海洋新材料有限公司

Aqueous polymer dispersions

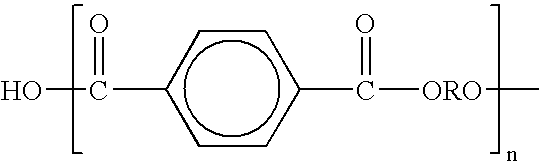

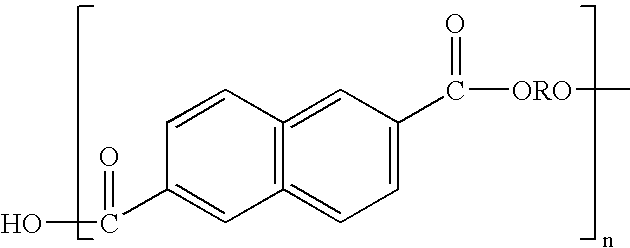

InactiveUS7129278B2Improved wet adhesionHigh glossEmulsion paintsPolyester coatingsPolymer scienceWater dispersible

The overall performance of water-reducible polymer dispersions, more specifically alkyd dispersions, can be substantially improved by utilizing resins derived from acidolysis reaction products of polyalkylene terephthalates and polyalkylene naphthalates. According to this invention, polymer dispersions can be produced from low acid value polymers and yet have good water dispersibility. When an aqueous coating composition is formulated using the dispersion of this invention, a final coating is formed that has good hydrolytic stability, and when blended with a latex, exhibits improved gloss and wet adhesion.

Owner:THE SHERWIN-WILLIAMS CO

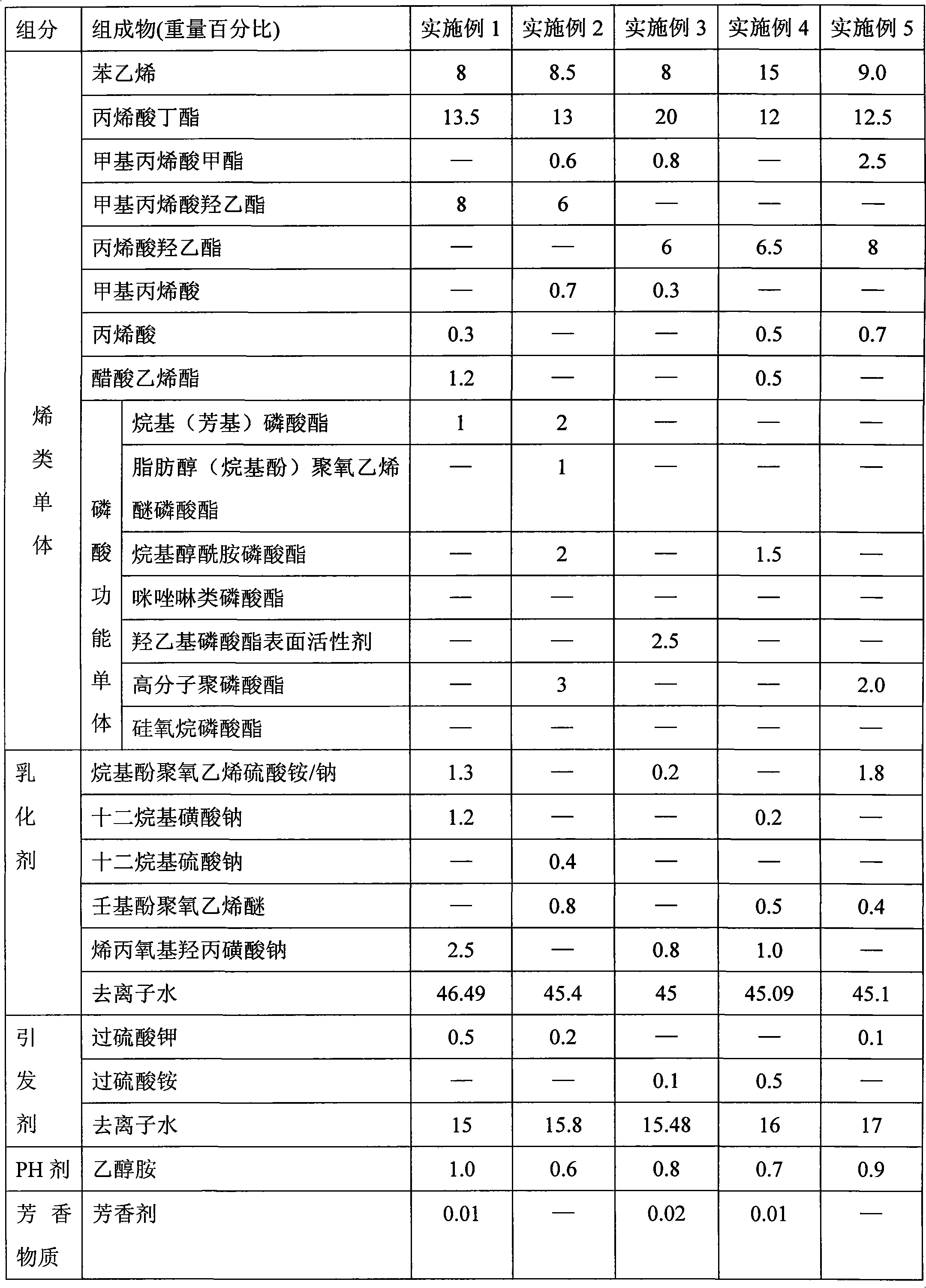

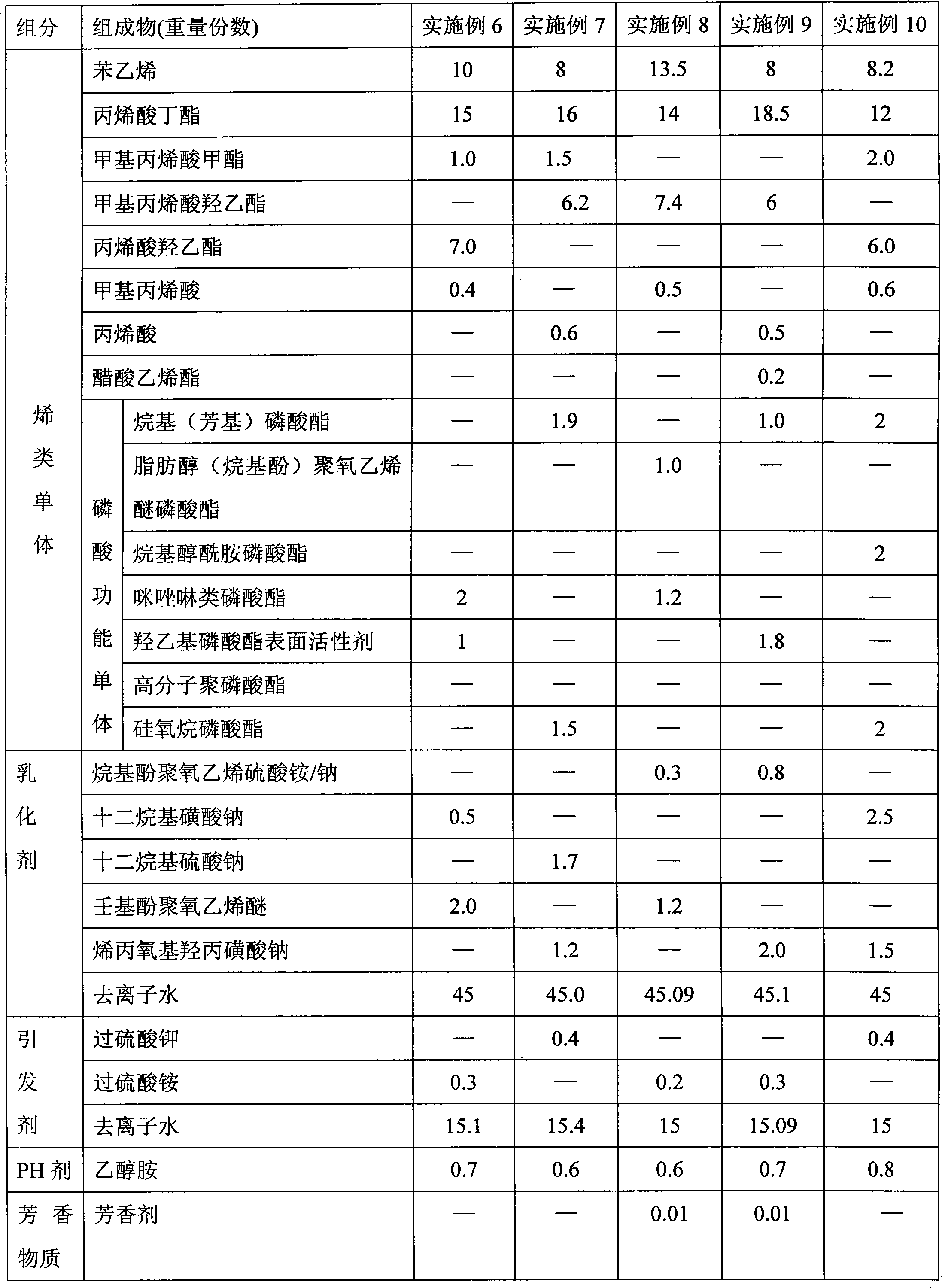

Anti-corrosion primer emulsion and preparation method thereof

InactiveCN102167771AImprove stabilityPromote environmental protectionAnti-corrosive paintsWater basedFunctional monomer

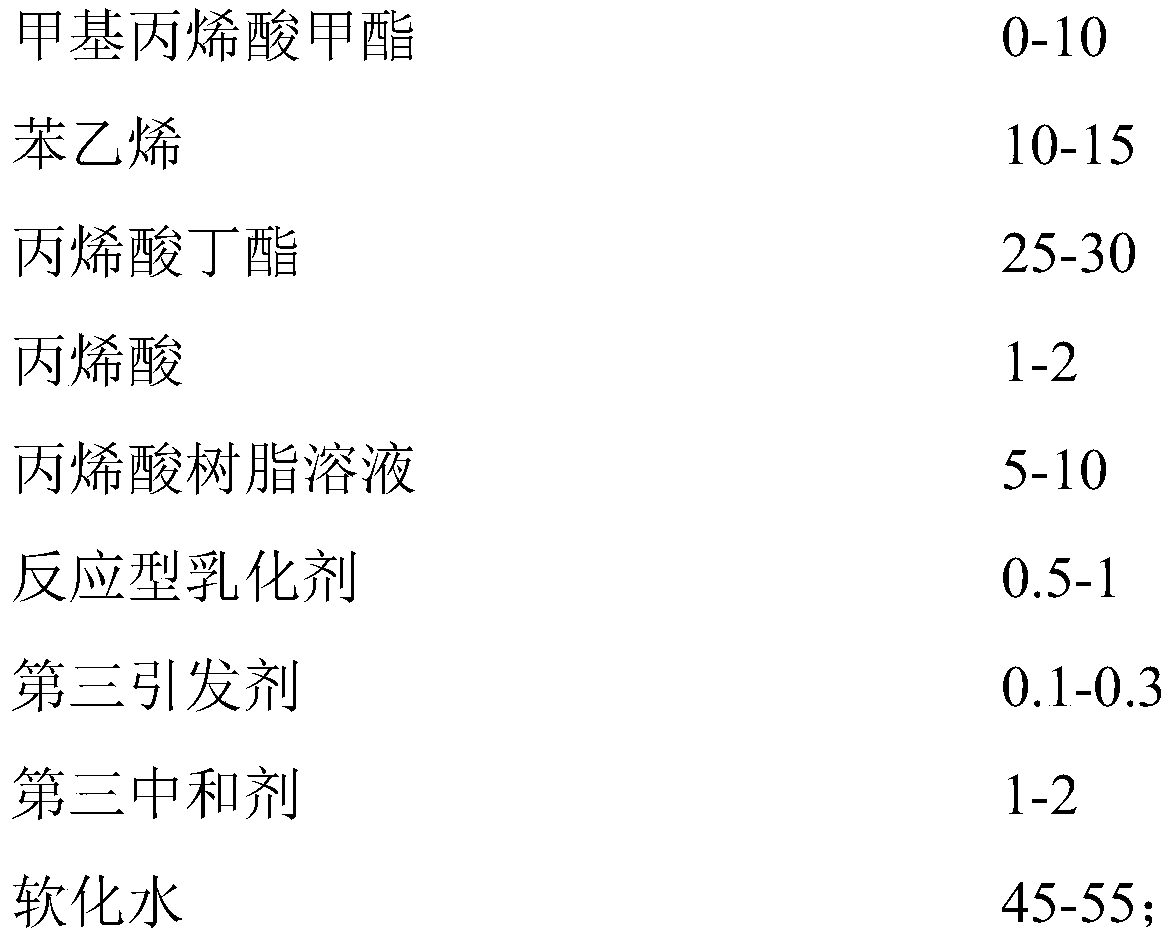

The invention discloses anti-corrosion primer emulsion for water-based high-corrosion-resistance air-conditioning aluminum foil paint and a preparation method thereof. The anti-corrosion primer emulsion comprises the following components in percentage by weight: 8 to 15 percent of styrene, 12 to 20 percent of butyl acrylate, 0 to 2.5 percent of methyl methacrylate, 6 to 8 percent of (methyl) ethyl acrylate, 0.3 to 0.7 percent of (methyl) acrylic acid, 0 to 1.2 percent of vinyl acetate, 1 to 8 percent of phosphate functional monomer, 1 to 5 percent of emulsifier, 0.1 to 0.5 percent of initiator, 0.6 to 1.0 percent of pH regulator and the balance of deionized water. In the preparation method of the acrylic acid emulsion, the phosphate functional monomer is added and a polymerizable composite emulsifier takes part in seeded emulsion polymerization, so that stability and corrosion resistance of the acrylic acid emulsion are improved.

Owner:SNTO TECH GRP

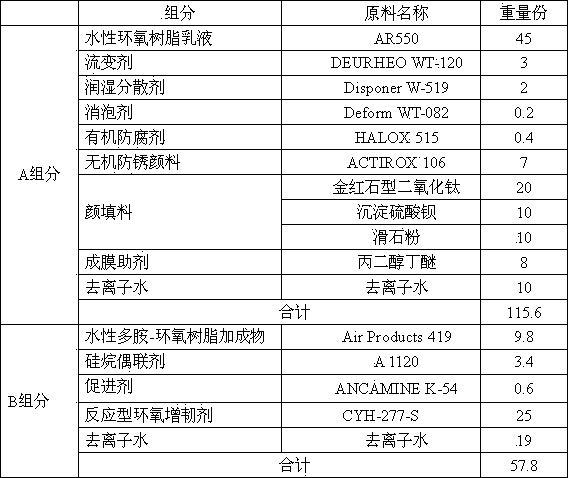

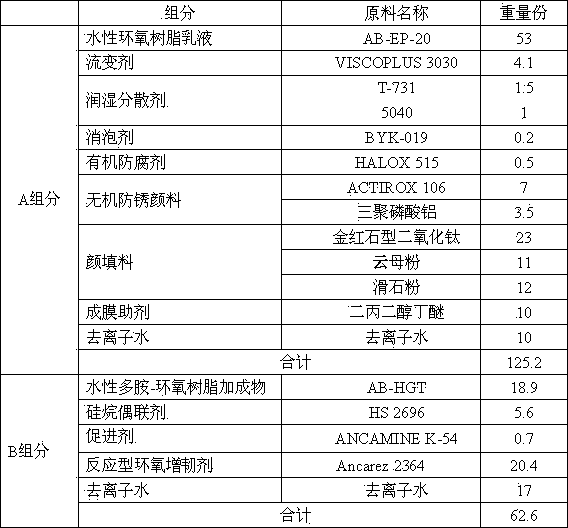

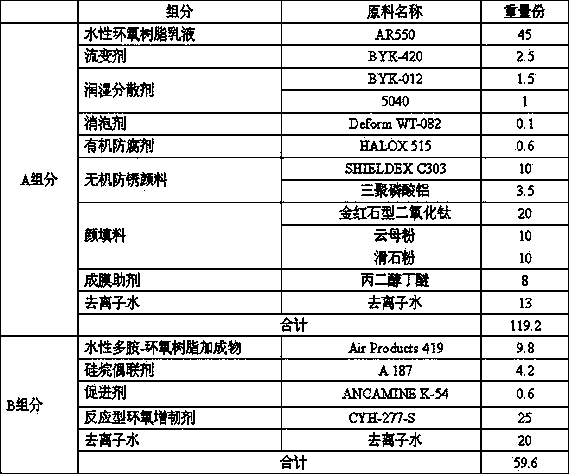

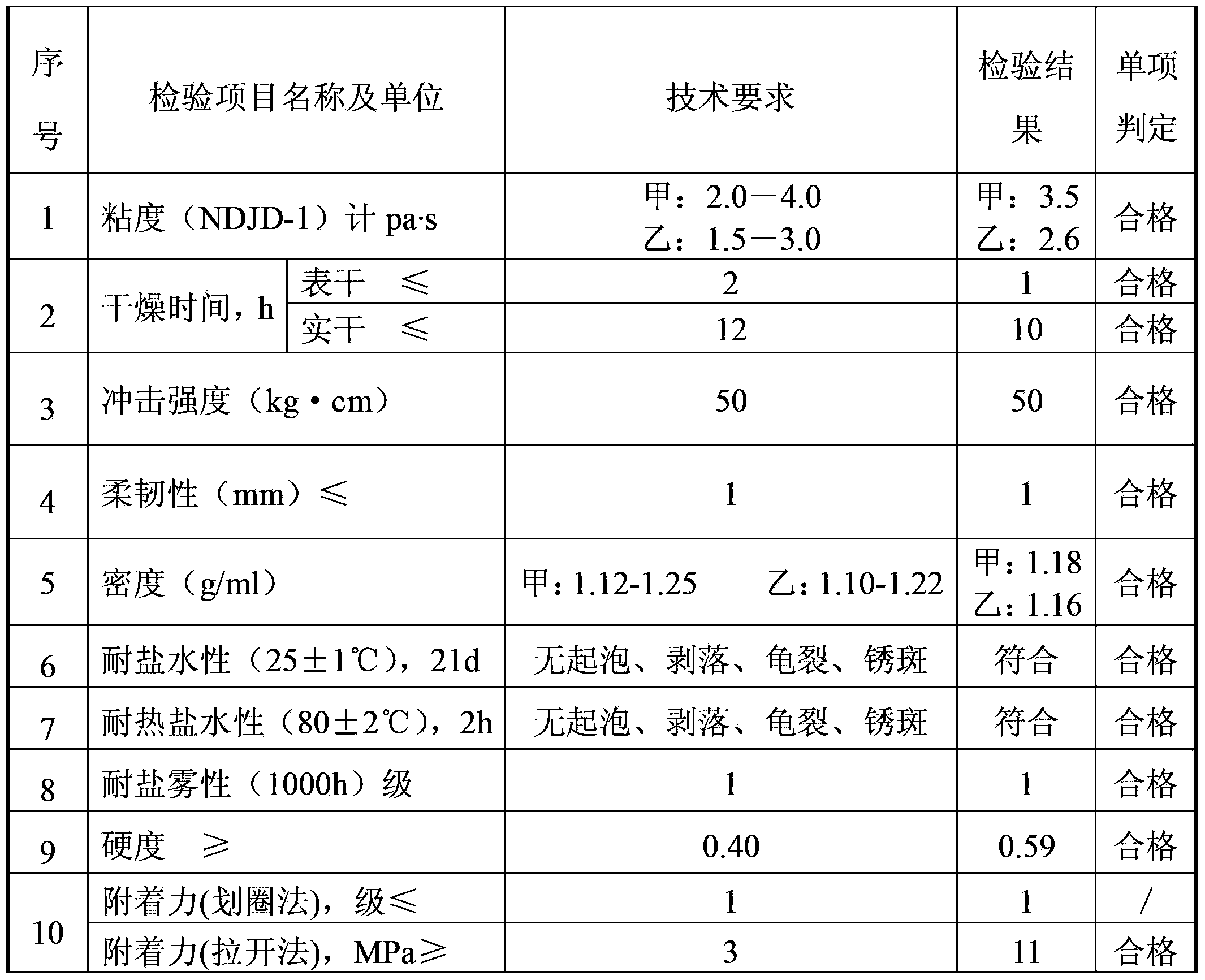

Aqueous epoxy corrosion-resistant coating for mechanical equipment and preparation method of aqueous epoxy corrosion-resistant coating

InactiveCN104277660ASpeed up the reaction processAvoid coating film brittle defectsAnti-corrosive paintsEpoxy resin coatingsIonEmulsion

The invention relates to an aqueous epoxy corrosion-resistant coating for mechanical equipment. According to the aqueous epoxy corrosion-resistant coating, a component A comprises an aqueous epoxy resin emulsion, a rheological agent, a wetting and dispersing agent, a defoaming agent, an organic preservative, an inorganic anti-rust pigment, a pigment filler, deionized water and a film-forming aid, a component B comprises an aqueous polyamine-epoxy resin adduct, deionized water, a silane coupling agent, a promoter and a reactive epoxy toughening agent, and the aqueous epoxy corrosion-resistant coating is prepared by preparing the component A, preparing the component B and mixing the component A and the component B. Test results show that under the situation of coating a 150mu m wet film, the surface drying time is less than 40min, the solid drying time is less than 12h, the thickness of a dry film is 80mu m, a coating has no cracks under the impact condition of 120kg.cm, an anti-flash rust agent which produces harm to a human body or an environment is eliminated, and the aqueous epoxy corrosion-resistant coating is environment-friendly and high in safety.

Owner:洛阳双瑞防腐工程技术有限公司

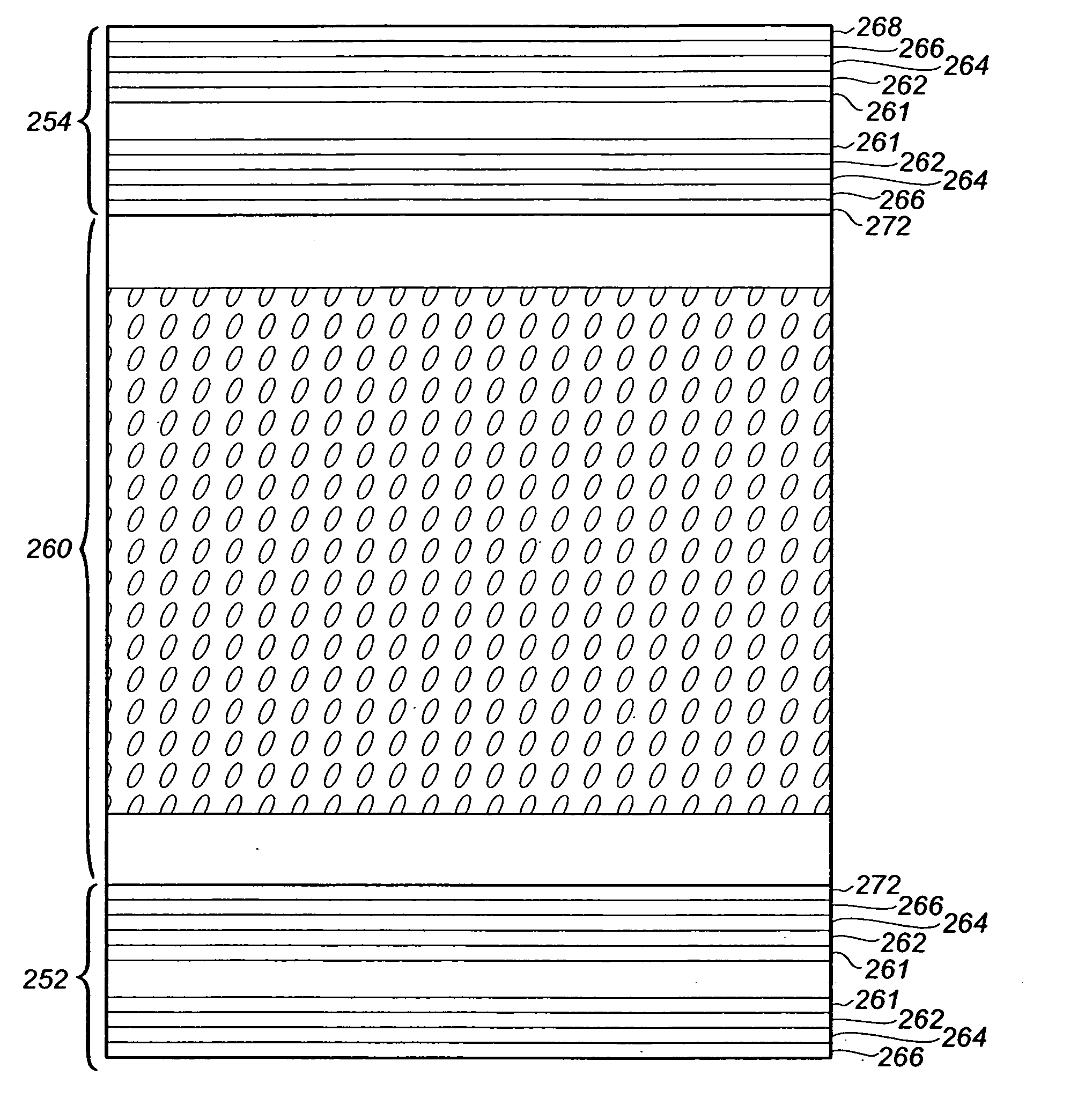

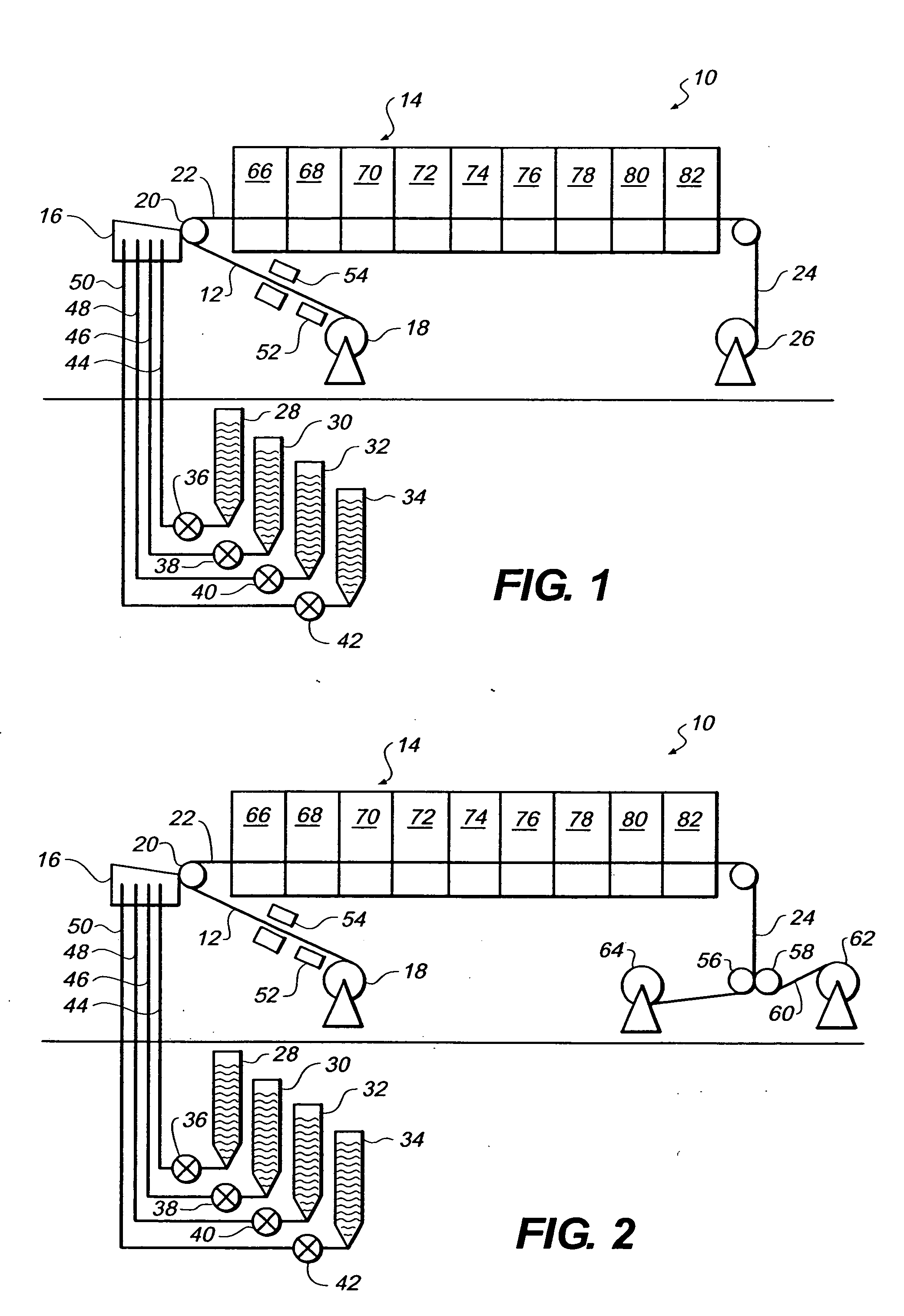

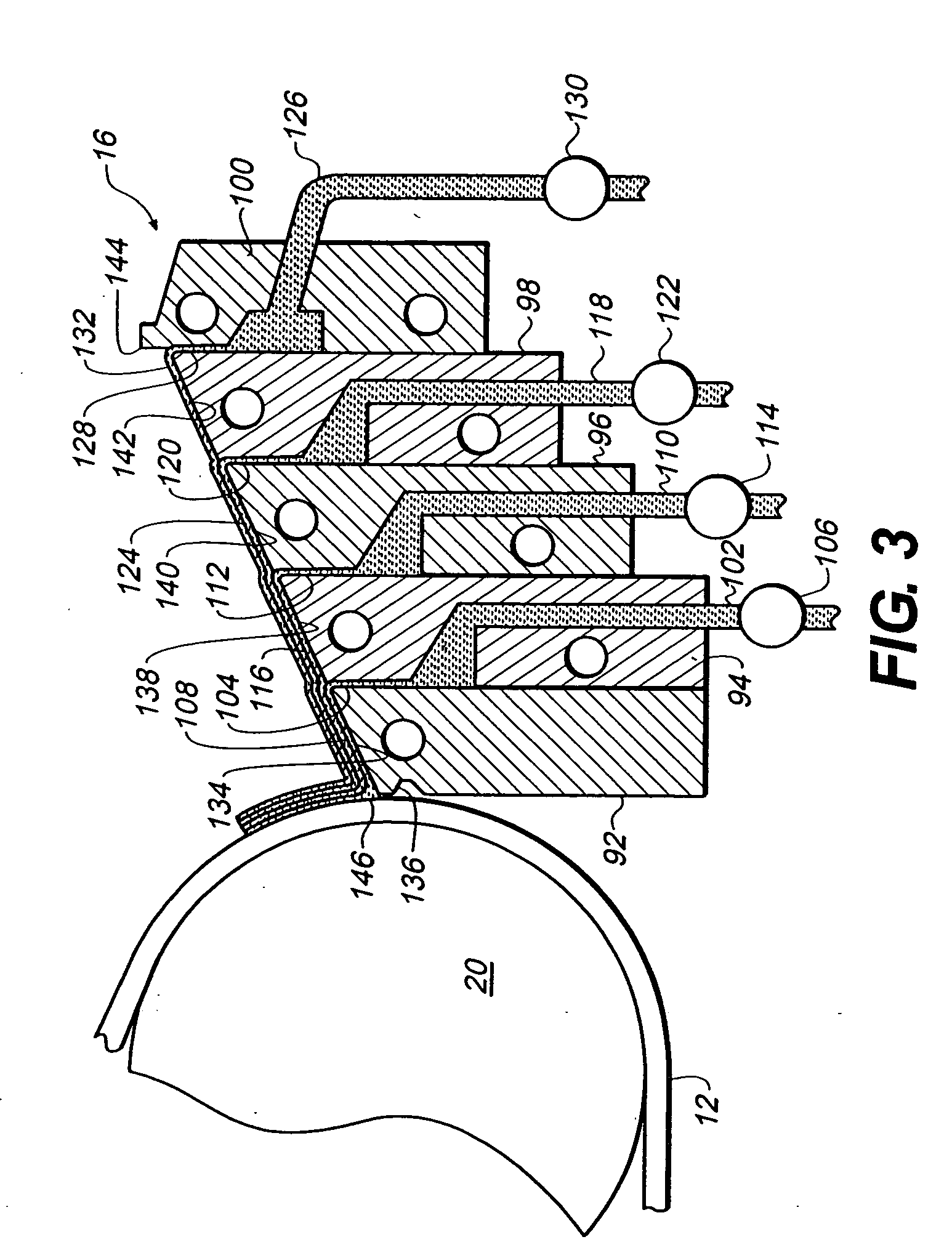

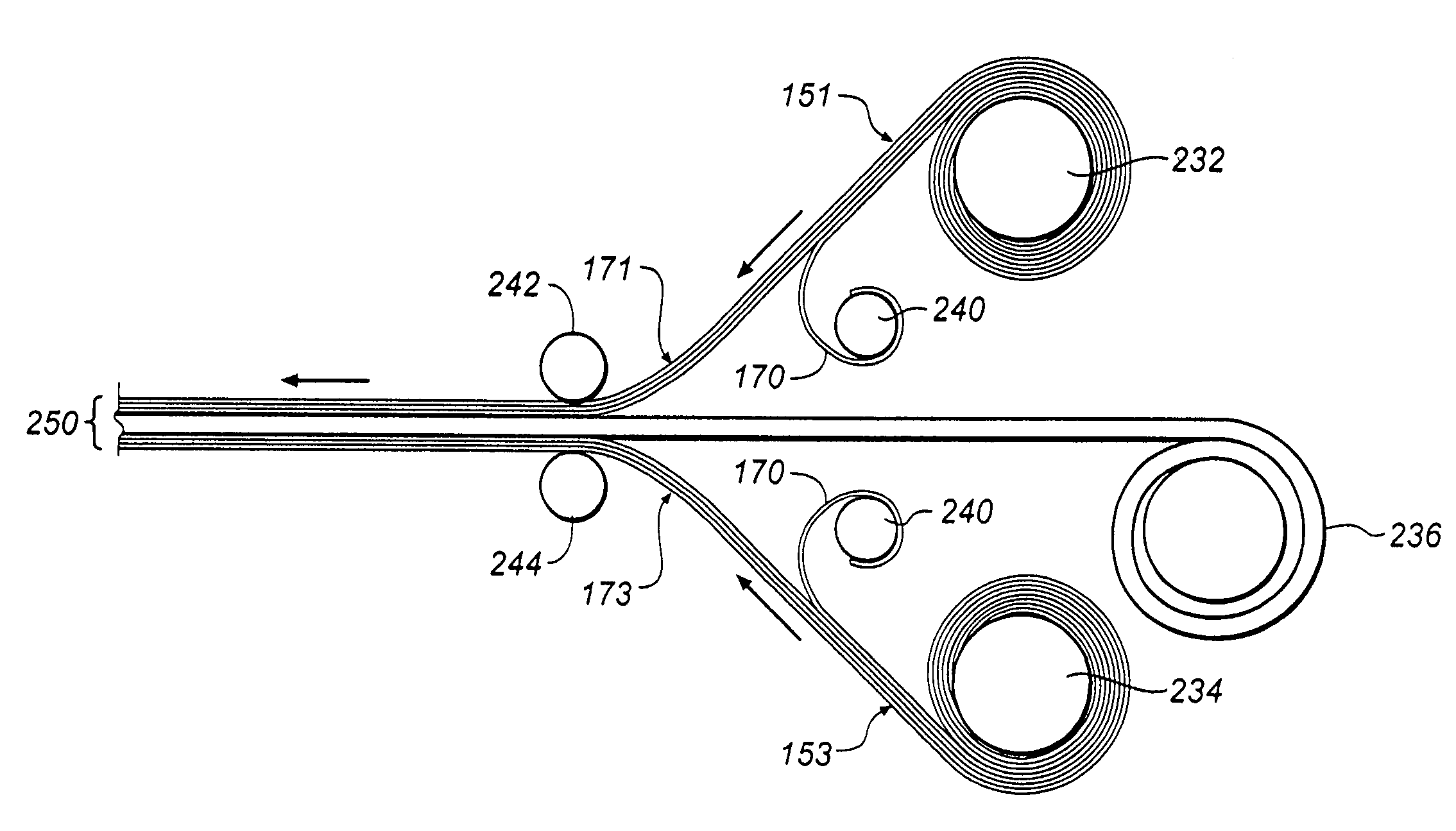

Polarizing plate laminated with an improved glue composition and a method of manufacturing the same

InactiveUS20060144514A1Improve dry adhesionImproved wet adhesionAdhesive processesSynthetic resin layered productsPolyvinyl alcoholEngineering

The present invention generally relates to method of forming a polarizing plate comprising providing two cover sheets each comprising a low birefringence protective polymer film and a layer promoting adhesion to poly(vinyl alcohol)-containing films that comprises a dissolved first poly(vinyl alcohol) having a degree of hydrolysis of at least 98%. A glue composition is applied when bringing the PVA dichroic polarizing film into contact with the cover sheets, the glue composition comprising a dissolved second poly(vinyl alcohol) having a degree of hydrolysis of at least 98% in combination with crosslinking agent.

Owner:EASTMAN KODAK CO

Solvent-free epoxy glass flake coating for sea splash zone steel structures and preparation method thereof

ActiveCN106047065AHigh viscosityEasy constructionAnti-corrosive paintsEpoxy resin coatingsPolyamideSolvent free

The invention discloses a solvent-free epoxy glass flake coating for sea splash zone steel structures and a preparation method thereof. The coating is composed of a component A and a component B. The component A comprises a bisphenol A epoxy resin, a hydrogenated bisphenol A epoxy resin, a reactive diluent, a defoaming agent, a leveling agent, a wetting and dispersing agent, a thickening thixotropic agent, a silane coupling agent, an ultraviolet absorbent, a salt-mist-resistant aid, titanium white, ferrophosphorus powder, mica powder, an antirust filler, 160-mesh glass flakes and 325-mesh glass flakes. The component B comprises a modified polyamide curing agent, a modified phenol formaldehyde amine hardener and an adhesion promoter. The coating is a solvent-free product, and has the advantages of environment friendliness, no toxicity and favorable constructability. The paint film has the advantages of favorable corrosion resistance, favorable seawater immersion resistance, favorable aging resistance and favorable cathodic disbonding resistance.

Owner:洛阳双瑞防腐工程技术有限公司

Polarizing plate laminated with an improved glue composition and a method of manufacturing the same

InactiveUS7399376B2Overcome limitationsEliminate needAdhesive processes with surface pretreatmentSynthetic resin layered productsEngineeringPolarizer

The present invention generally relates a method of forming a polarizing plate comprising providing two protective cover sheets, each protective cover sheet for polarizers comprising a low birefringence protective polymer film and a layer promoting adhesion to poly(vinyl alcohol)-containing films comprising a hydrophilic polymer. The cover sheets are brought into contact with a PVA dichroic polarizing film such that said layer promoting adhesion to poly(vinyl alcohol)-containing films in each of said two cover sheets is in contact with said PVA dichroic polarizing film. A glue composition is applied just before contacting said PVA dichroic polarizing film and said cover sheets, said glue composition being substantially free of dissolved polymer and comprising a crosslinking agent that crosslinks PVA.

Owner:EASTMAN KODAK CO

Hot melt adhesive for disposable products

ActiveUS20140199907A1Improve adhesionSmall smellSynthetic resin layered productsWoven fabricsWaxPolymer science

The present invention provides a hot melt adhesive suitable for use in disposable products, which can be applied at a high speed and provides excellent in adhesion in a wet state and low-temperature coating, with little odor. The hot melt adhesive for disposable products comprises: (A) a propylene homopolymer having a melting point of 100° C. or lower obtained by polymerizing propylene using a metallocene catalyst; and (B) a wax modified with carboxylic acid and / or carboxylic acid anhydride. The wet adhesion of the hot melt adhesive is improved when the wax is modified with maleic acid and / or maleic anhydride.

Owner:HENKEL KGAA

Sealing agent

Disclosed herein are coating agents and methods of manufacturing coated products with such coating agents. The disclosed coating agents may include at least one resin, at least one filler selected from the group comprising natural mineral and synthetic mineral, and at least one chemical agent, wherein the at least one chemical agent is at least one pigment selected from the group comprising inorganic pigment and organic pigment.

Owner:JAMES HARDIE TECH LTD

Process for producing a multilayer coating

InactiveUS20100272886A1Improve adhesionImprove interlayer adhesionLayered productsLaminationWater basedCross-link

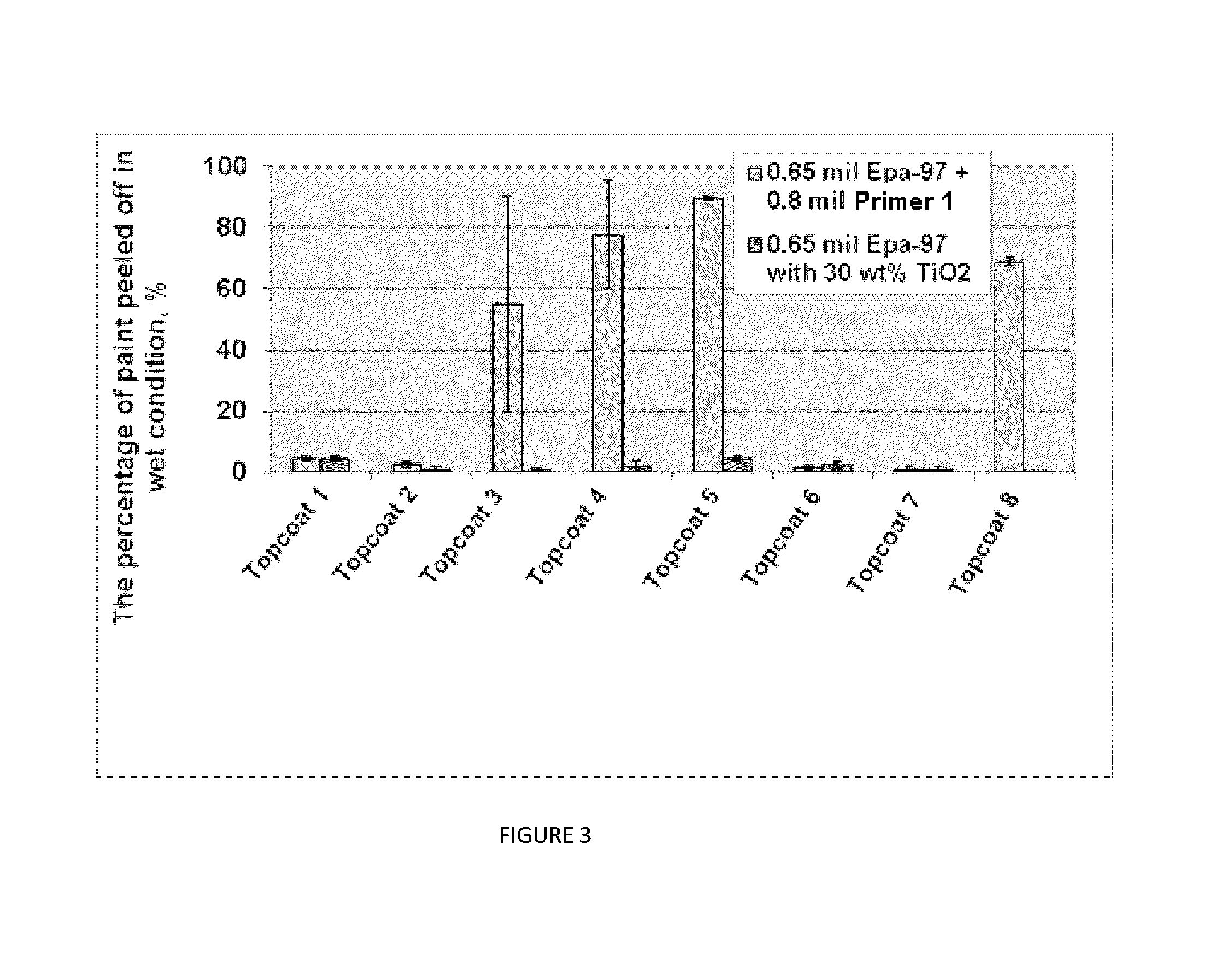

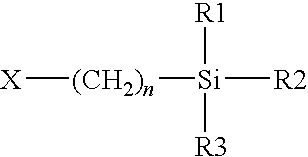

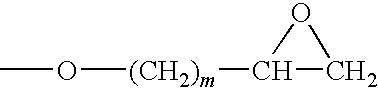

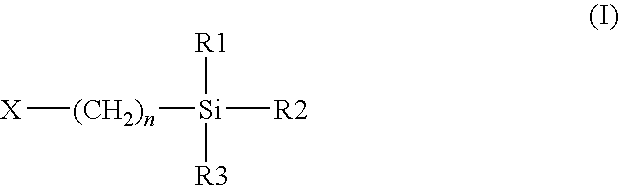

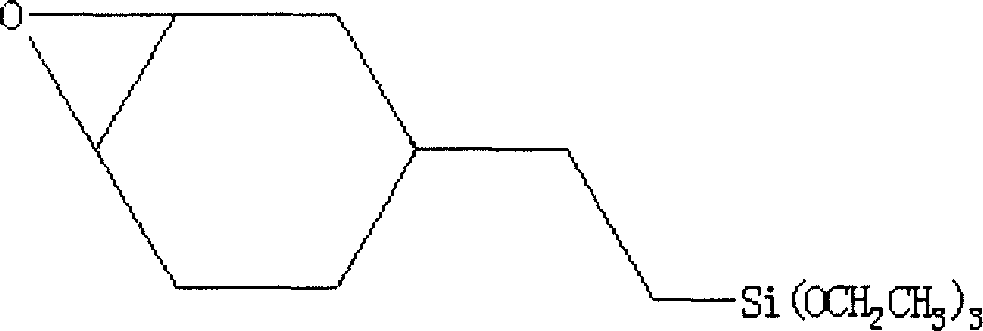

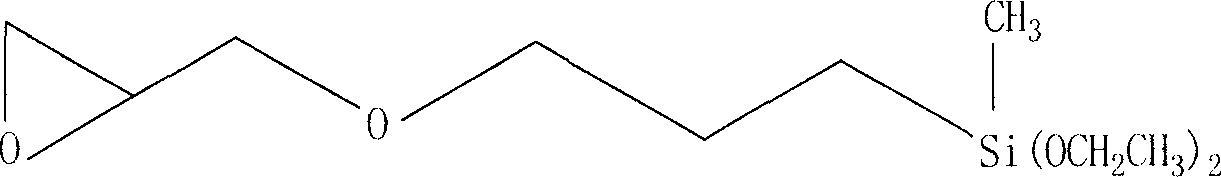

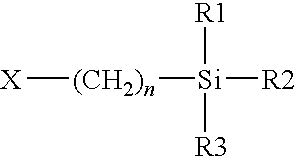

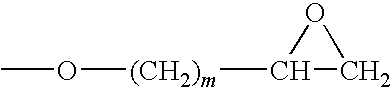

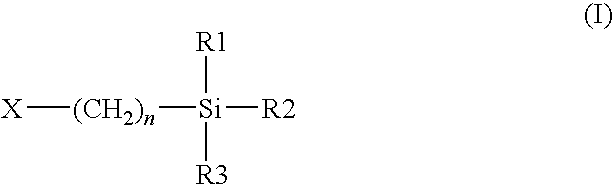

The invention relates to a process for the multilayer coating of substrates, in particular vehicle bodies and vehicle body parts, comprising the steps:1. Applying a base coat layer of a water-based base coat composition containing color-imparting and / or special effect-imparting pigments onto an optionally precoated substrate, 2. Applying a clear coat layer of a transparent clear coat coating composition onto the base coat layer, and 3. Curing the clear coat layer, optionally together with the base coat layer, wherein the transparent clear coat coating composition being an organic solvent-based coating composition comprising:A) at least one binder with functional groups containing active hydrogen,B) at least one polyisocyanate cross-linking agent with free isocyanate groups, andC) at least one epoxy-functional silane of the general Formula (I):X denoting the residueswith m being 1-4, or 3,4-epoxycyclohexyl, R1, R2, R3 mutually independently meaning identical or different organic residues with 1 to 30 carbon atoms per molecule, providing that at least one of the residues is an alkoxy group with 1 to 4 carbon atoms and n is 2, 3 or 4.

Owner:AXALTA COATING SYST IP CO LLC

Tar-free epoxy resin coating and its preparation method

InactiveCN103360904AStrong adhesionHigh mechanical strengthAnti-corrosive paintsEpoxy resin coatingsEpoxyPetroleum resin

The invention relates to an epoxy coating and its preparation method. The coating provided by the invention comprises a component A and a component B, wherein the component A comprises 20-35 wt% of an epoxy resin liquid, 4-15 wt% of a phenolic resin liquid, 4-15 wt% of a petroleum resin liquid, 1-7 wt% of an anti-settling agent, 20-50 wt% of a filler, 4-15 wt% of a pigment, 5-20 wt% of a solvent and 0.3-5 wt% of a cosolvent; the component B comprises 30-80 wt% of a curing agent and 20-70 wt% of a solvent; and the mass ratio of the component A to the component B is 10-1:1. The coating provided by the invention has a light color, is suitable for a priming paint and a finishing coat, and has good waterproof and antirust properties.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

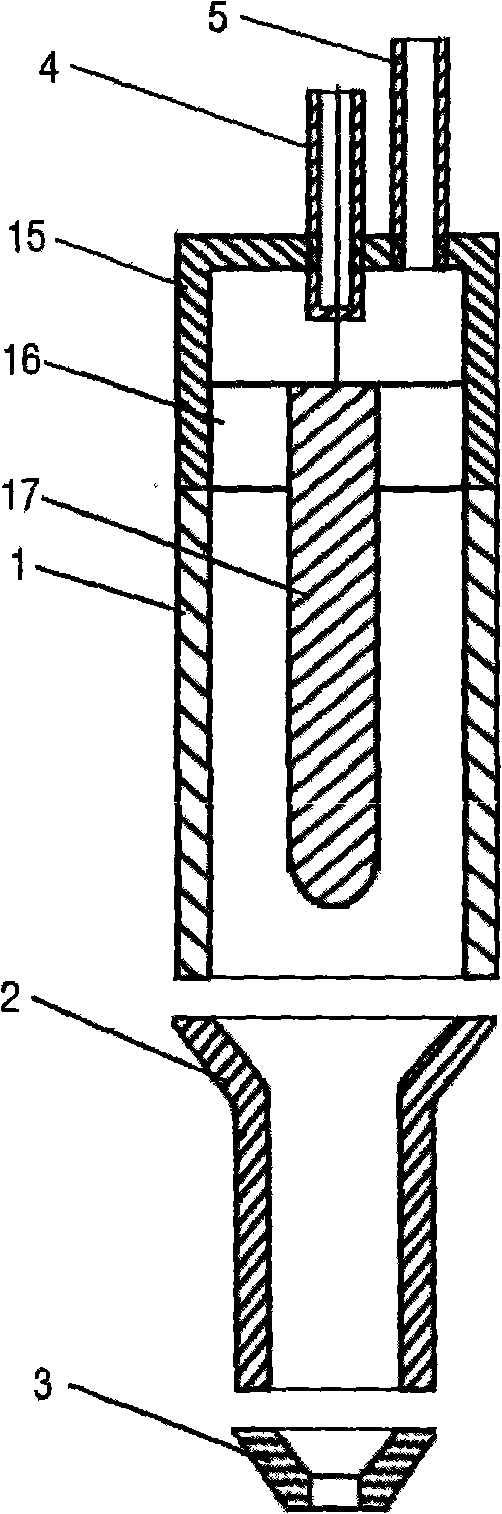

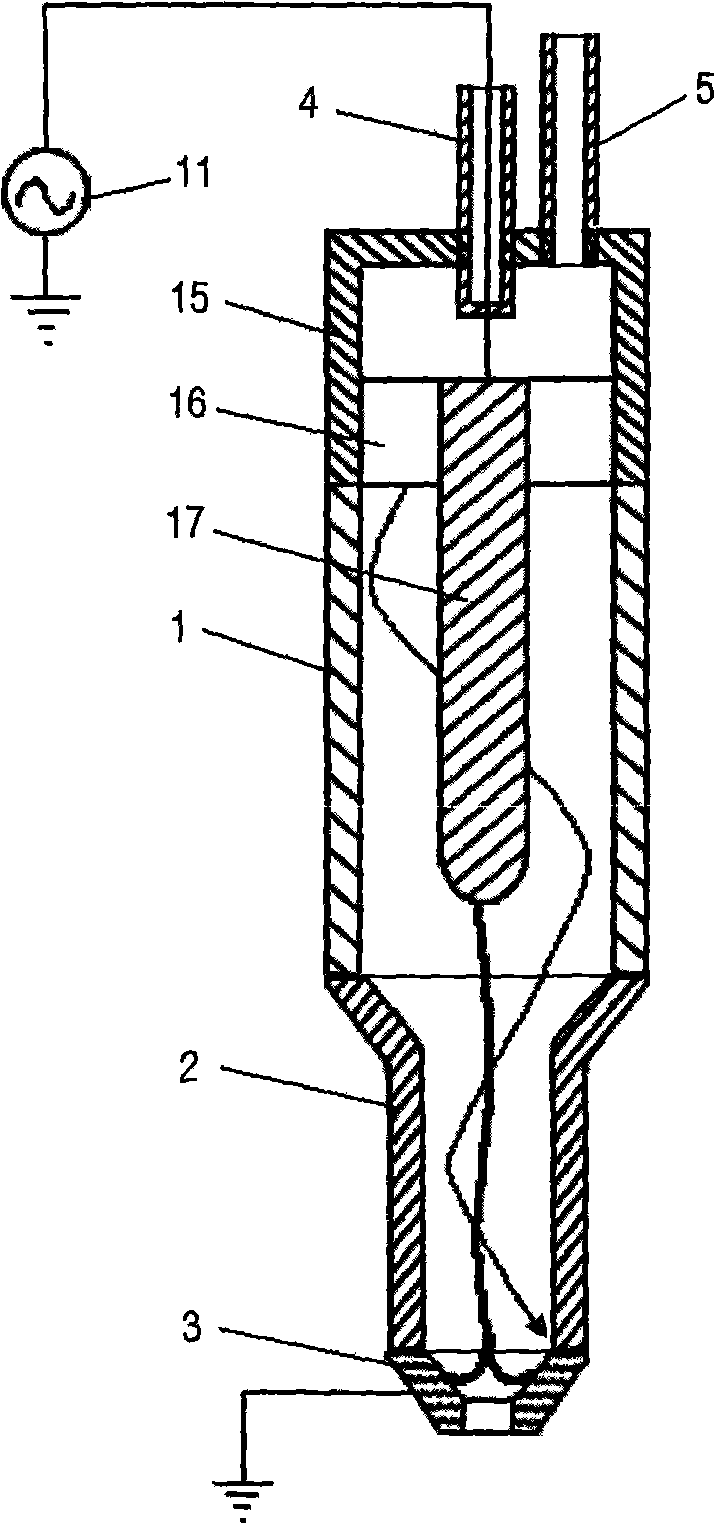

Method for improving surface energy of aluminum plate by using plasma

InactiveCN101638015AIncrease the specific surface area of contactImprove wet adhesionPretreated surfacesCoatingsEtchingSurface cleaning

The invention relates to a method for improving surface energy of an aluminum plate by using a plasma, which is characterized in that a plasma generating device is used for generating the plasma, andactivation treatment of the surface of the ordinary aluminum plate is implemented by leading the ordinary aluminum plate to pass through the plasma, so as to achieve the purpose of improving the surface energy of the aluminum plate, then ink is jetted on the surface of the aluminum plate after treatment, and the ordinary aluminum plate refers to an aluminum alloy plate which leads the surface to form dense sand meshes by the technologies of electrolytic coarsening and anode oxidation. The method has the advantages that the uniformity of the surface treatment is good, the method has the roles of surface cleaning and etching and can increase the contract specific surface area and improve the wetting adhesion and the spreadability, a coating layer can be very thin, the method does not have the problems of uncoating and uneven coating and simultaneously avoids the negative impacts on the surface appearance of the plate due to the use of a surfactant, the surface treatment is directly carried out on the surface of a sand mesh layer, the method does not use an intermediate layer, active particles can generate strong chemical bonds, improve the adhesion and lead the press run of a produced printing plate to be high, the production cost is low and the treatment speed is fast.

Owner:中国印刷科学技术研究所

Cell cathode and lithium ion cell using the same and their manufacture methods

ActiveCN1953252AImprove cycle performanceGood wet adhesionElectrode manufacturing processesActive material electrodesEpoxySilanes

The invention relates to a cathode of lithium battery and relative battery. Wherein, said cathode comprises collecting element, and the cathode material coated and / or filled in collecting element; said cathode material comprises cathode active component and adhesive; said adhesive comprises carboxyl polymer; the adhesive contains epoxy silane. The inventive battery has better circulate property.

Owner:BYD CO LTD

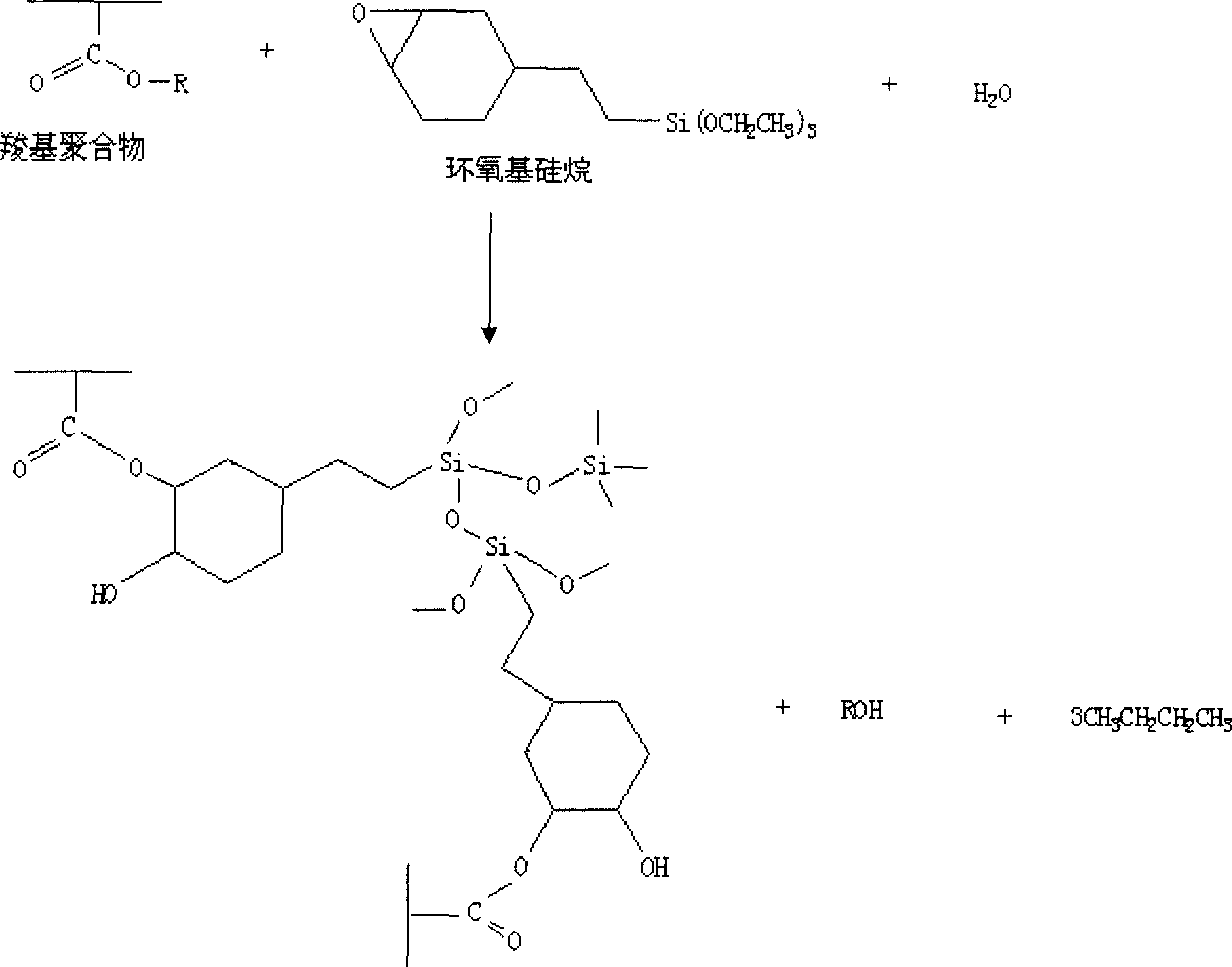

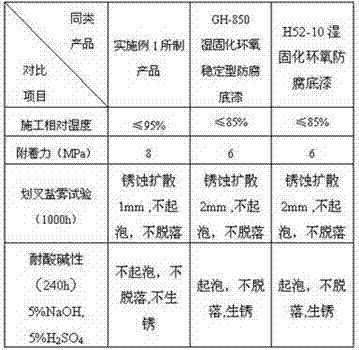

Moisture-curing epoxy zinc phosphate over-rust primer

ActiveCN102898928AChemically stableFirm textureAnti-corrosive paintsEpoxy resin coatingsEpoxyCyclohexanone

The invention provides a moisture-curing epoxy zinc phosphate over-rust primer which is prepared by mixing a component A and a component B in a weight ratio of 8:1, wherein the component A comprises 35-50% of epoxy resin, 5-7% of 509 zinc chrome yellow, 5-7% of 309 zinc chrome yellow, 5-7% of 109 zinc chrome yellow, 5-8% of iron oxide red, 6-8% of zinc phosphate, 5-9% of aluminum tripolyphosphate, 6-9% of diphenyl guanidine chromate, 6-8% of dimethylbenzene, 2-4% of n-butanol and 5-8% of cyclohexanone; and the component B comprises 85-90% of ketoimine modified fatty acid epoxy resin, 5-10% of dimethylbenzene and 3-5% of n-butanol. The invention has the advantages of excellent film-forming property, excellent anticorrosive and anti-rust properties, favorable adhesive force for the substrate, favorable flexibility and favorable impact resistance, and can quickly cure to form a film in a high-humidity environment (the relative humidity is less than or equal to 95%).

Owner:江苏纽克莱涂料有限公司

Ship hull rust-proof two-component epoxy coating

InactiveCN105385296AExcellent metal adhesionGood chemical resistanceAnti-corrosive paintsEpoxy resin coatingsSolventChemistry

The invention discloses ship hull rust-proof two-component epoxy coating which comprises a component A and a component B, wherein the component A is prepared from the following raw materials in parts by weight: 30 to 60 parts of bisphenol A epoxy resin, 20 to 40 parts of modified bisphenol F epoxy resin, 15 to 30 parts of amino resin, 20 to 35 parts of mixed solvent, 10 to 20 parts of nano-silica, 20 to 40 parts of filler, 1 to 3 parts of silane coupling agent, 1 to 2 parts of chlorinated paraffin, 1 to 2 parts of dibutyl ester, 1 to 2 parts of anti-settling agent, 1 to 2 parts of flatting agent, 1 to 2 parts of thixotropic agent, 1 to 2 parts of dispersing agent and 1 to 2 parts of defoaming agent; the component B is prepared from the following raw materials in parts by weight: 10 to 20 parts of phenol-aldehyde amine, 5 to 10 parts of 1,3-diamido-hexylamine, 1 to 3 parts of butanol and 1 to 6 parts of xylene; the weight ratio of the component A and the component B is 10 to (1 to 1.5). The coating provided by the invention is environment-friendly, and is good in cathodic disbonding resistance.

Owner:ANHUI JINDUN PAINT

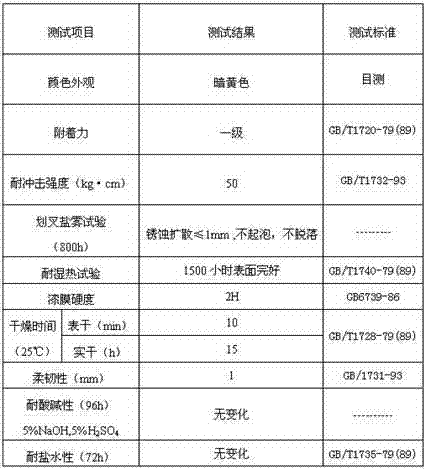

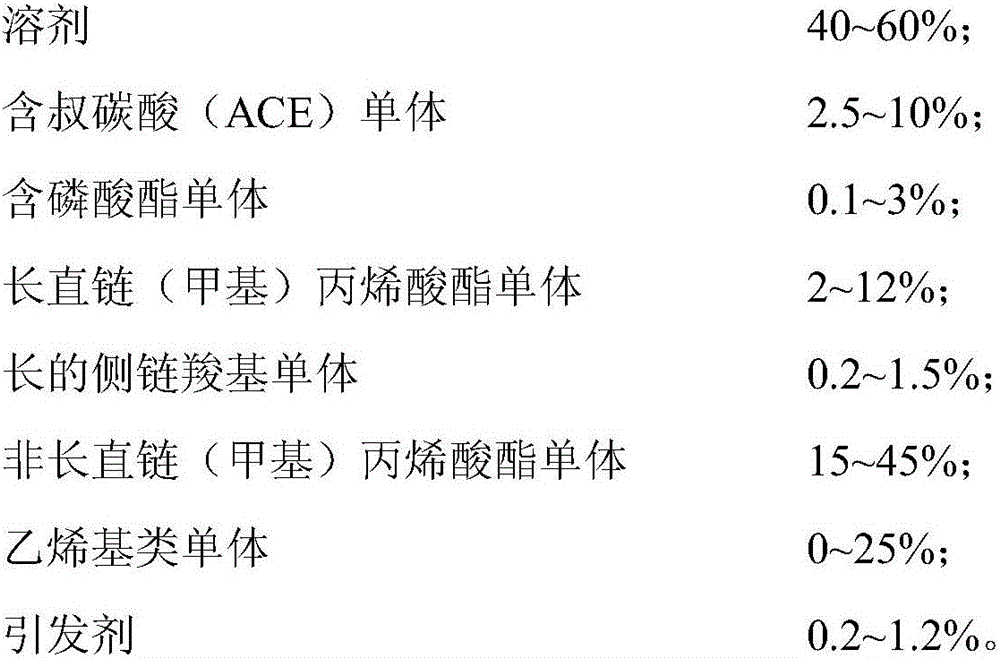

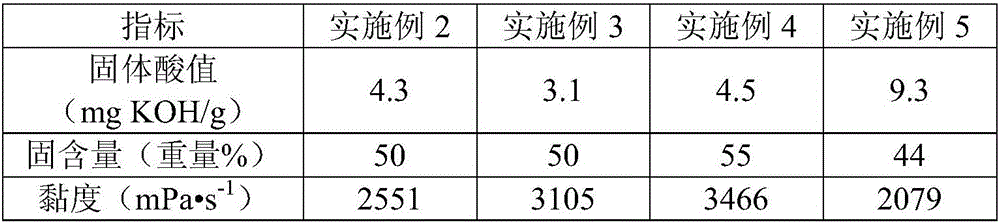

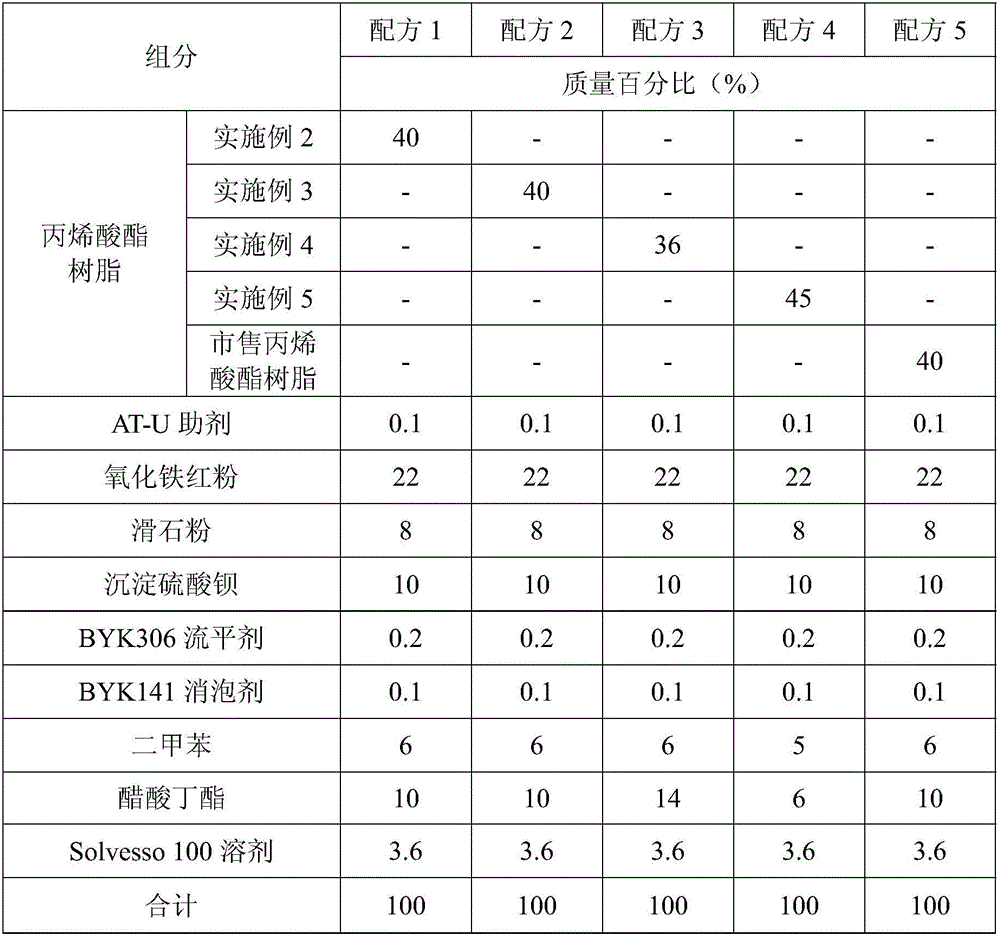

High-corrosion resistance acrylate resin and preparation method thereof

ActiveCN106749852AGood weather resistancePrevent infiltrationAnti-corrosive paintsCoating systemPhosphate

The invention provides a high-corrosion resistance acrylate resin. A macromolecular tert-carbonyldioxy group, a phosphate-containing group, long-straight chain (meth)acrylate and a long-side chain carboxyl group are uniformly distributed in the molecule chain segment of the high-corrosion resistance acrylate resin, and the acrylate resin comprises, by mass, 40-60% of a solvent, 2.5-10% of a tert-carbonic acid-containing monomer, 0.1-% of a phosphate ester-containing monomer, 2-12% of a long-straight chain (meth)acrylate monomer, 0.2-1.5% of a long-side chain carboxyl monomer, 15-45% of a non-long-straight chain (meth)acrylate monomer, 0-25% of a vinyl monomer and 0.2-1.2% of an initiator. The invention also provides a preparation method of the acrylate resin and a single-component acryalte coating prepared from the acrylate resin. The acrylate resin has excellent weather resistasnce, excellent chemical resistance and good corrosion resistance, and the single-component acryalte coating prepared in the invention has strong adhesion to a substrate, so the single-component acryalte coating can be widely applied to anticorrosive coating systems as a bottom and surface integrated coating.

Owner:上海华谊涂料有限公司

Fluoropolymer anticorrosive coating for fastener and preparation method thereof

ActiveCN103342957AEasy loading and unloadingImproved wet adhesionAnti-corrosive paintsEpoxy resin coatingsEpoxyPolymer science

The invention belongs to the technical field of preparation of anticorrosive coatings, and relates to a fluoropolymer anticorrosive coating for a fastener and a preparation method thereof. The preparation method comprises the following steps of: selecting N-methyl pyrrolidone dissolving liquor of polyamide-imide as a bonding primer, wherein the fluoropolymer novolac epoxy resin paint is anticorrosive finishing coating; first, brushing and curing the primer on the fastener, and then, brushing the coating of the finishing coating; drying the primer coating of polyamide-imide for 1-2 hours at 100-150 DEG C, and curing for 3-60 minutes at 280-340 DEG C; naturally drying the finishing coating prepared by novolac epoxy resin at normal temperature, then, drying for 0.5-3 hours at 50-90 DEG C, and curing for 0.5-2 hours at 180-200 hours to prepare the anticorrosive coating. The coating is simple in integral preparation process, easy to obtain raw materials, environment-friendly in preparation environment, good in anticorrosive performance of the product, long in service life, low in cost and good in economic benefit.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Waterborne two-component zinc-rich special epoxy curing agent and preparation method thereof

PendingCN110669205ALow viscosityImproved wet adhesionAnti-corrosive paintsEpoxy resin coatingsPolymer sciencePolyethylene glycol

Belonging to the technical field of zinc-rich primer curing agents, the invention discloses a waterborne two-component zinc-rich special epoxy curing agent and a preparation method thereof. The methodincludes the steps of: (1) preparation of a first curing agent: a. reacting polyethylene glycol with epoxy resin under a catalytic condition to obtain an epoxy-terminated polymer; b. in a nitrogen atmosphere, putting acid anhydride into a special amine component for ring-opening reaction; c. adding a basic amine component into a product of the ring-opening reaction, and carrying out amine esterification reaction to obtain an amide polymer; and d. putting the epoxy-terminated polymer into the amide polymer, and adding an end-capping reagent for end capping to obtain the first curing agent; and(2) preparation of a second curing agent: under a catalytic condition, subjecting oleic acid and basic amine to dehydration polymerization into low molecular weight polyamide, thus obtaining the second curing agent. The curing agent provided by the invention can cooperate with waterborne epoxy resin to generate a paint film, which has the characteristics of good wet adhesion and excellent salt spray resistance, thus having good application prospects.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

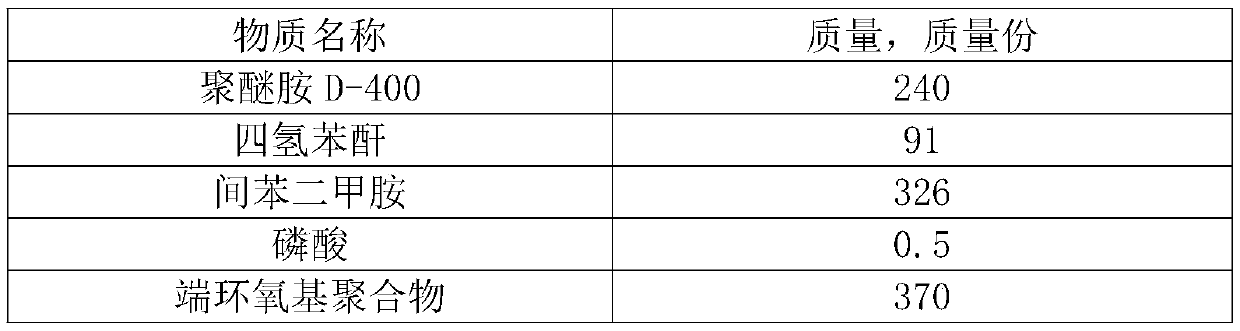

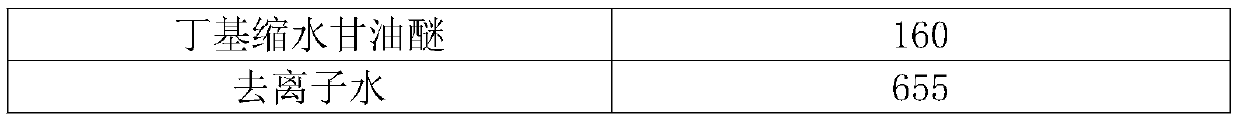

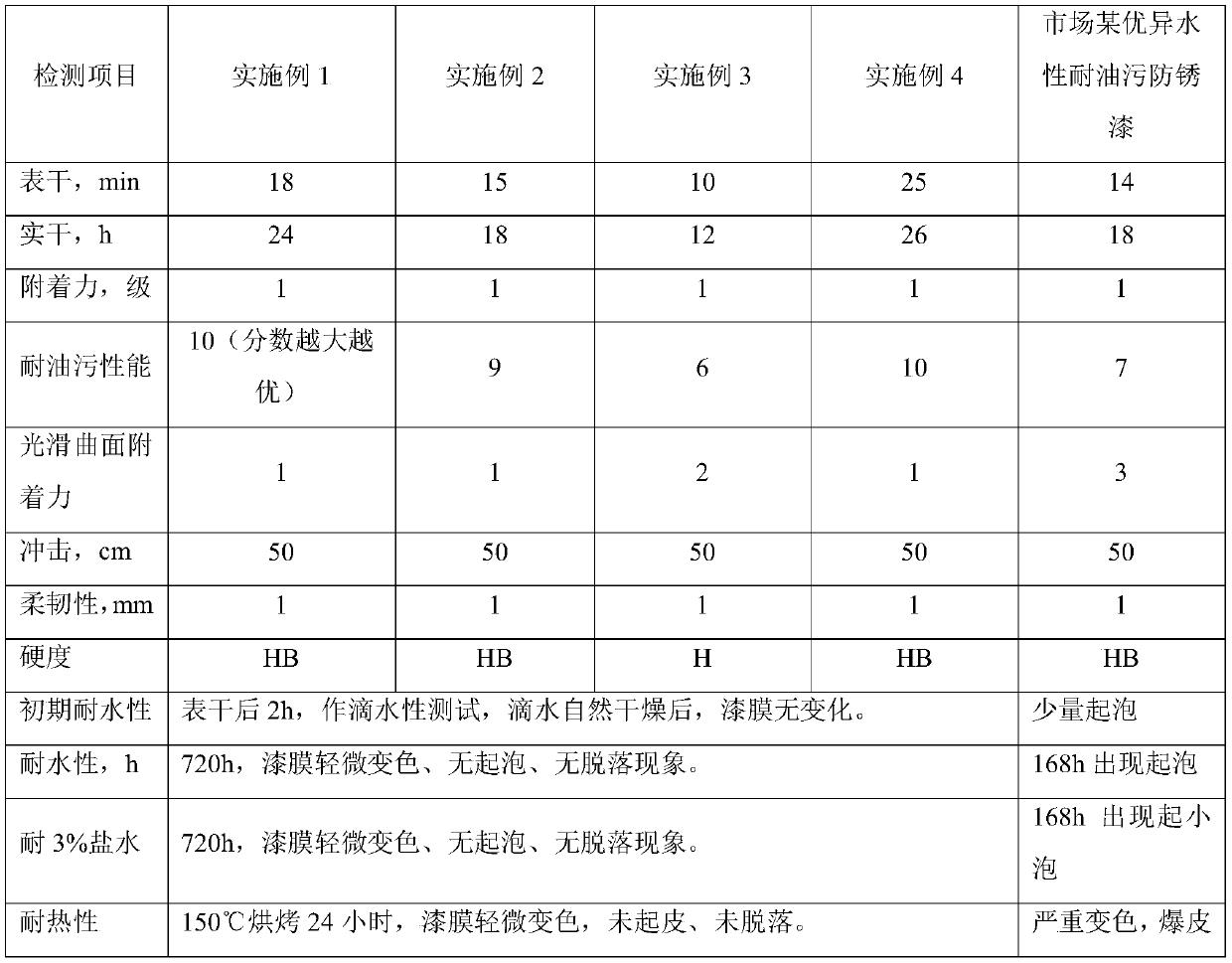

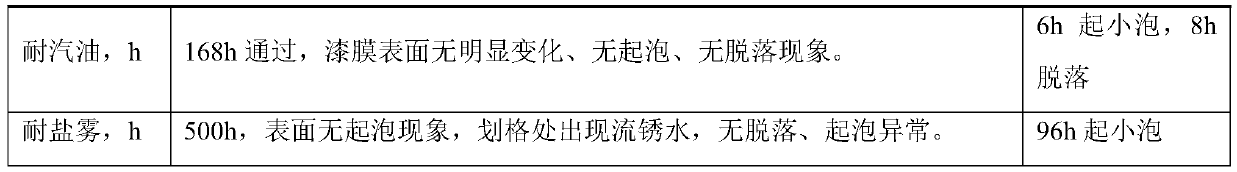

Oil stain-resistant and antirust water-based modified acrylic iron red primer and preparation method thereof

InactiveCN110499079AImprove freeze-thaw stabilityImprove water resistanceFireproof paintsAntifouling/underwater paintsWater basedEpoxy

The invention provides an oil stain-resistant and antirust water-based modified acrylic iron red primer and a preparation method thereof. The primer comprises, by mass, 22.5-30% of a water-based acrylic emulsion, 3-10% of a waterborne epoxy ester resin, 0.25-0.5 % of a water-based dispersant, 0.2-0.4% of a water-based defoaming agent, 0.1-0.4% of a water-based base material wetting agent, 0.4-0.8% of an anti-flash rust agent, 5.3-10.1 % of deionized water, 3-6% of a film-forming additive, 0.2-0.4% of a drier, 0.3-0.5% of organic bentonite, 0.3-0.5% of fumed silica, 10-15% of iron oxide red, 27-32% of coarse whiting, 4-7% of water-based zinc phosphate, 3-5% of sericite, 3-4% of water-based aluminum phosphate and 0.2-0.4% of a water-based thickener. The product disclosed by the invention has the characteristics of good substrate oil stain resistance, good wetting adhesion on an oily repaired workpiece, and good wetting adhesion on a smooth curved surface, and a thick film formed by theproduct has the characteristics of no cracking, excellent impact bending resistance, good freeze-thaw resistance stability, good water resistance, excellent corrosion resistance, good heat resistanceand excellent adhesion; and the product can be widely applied to the fields of various large steel structures, automobile chassis paints, automobile water tanks, train chassis paints and engineering machines.

Owner:成都拜迪新材料有限公司

Glyoxal adhesive system and process for manufacturing same

ActiveUS9315693B2Improved wet adhesionAvoid shootingNon-macromolecular adhesive additivesOptical articlesWater basedGlyoxal

Owner:ESSILOR INT CIE GEN DOPTIQUE

Waterborne binder and preparation method and application thereof

ActiveCN107652857AImproved wet adhesionExcellent pull-out adhesionAnti-corrosive paintsEpoxy resin coatingsEpoxyEmulsion

The invention provides a waterborne binder, comprising components A and B; the component is made from, by weight, 40-60 parts of waterborne epoxy acrylic emulsion, 22-48 parts of a pigment-filler, 1-2parts of a film-forming agent, 2-3 parts of an aid, and 12-30 parts of water; the component B is made from, by weight, 3-4.5 parts of a curing agent. The waterborne binder is applicable to containerprimers, has the same effect as oil primers to protect the integrity of container bodies, has excellent wet adhesion, pull adhesion and pull strength, has an equivalent active cycle to oil primers, has good resistance to salt fog, is green, and never causes a reduction to the customers' existing production rhythm.

Owner:BAUHINIA PAINTS SHANGHAI CO LTD

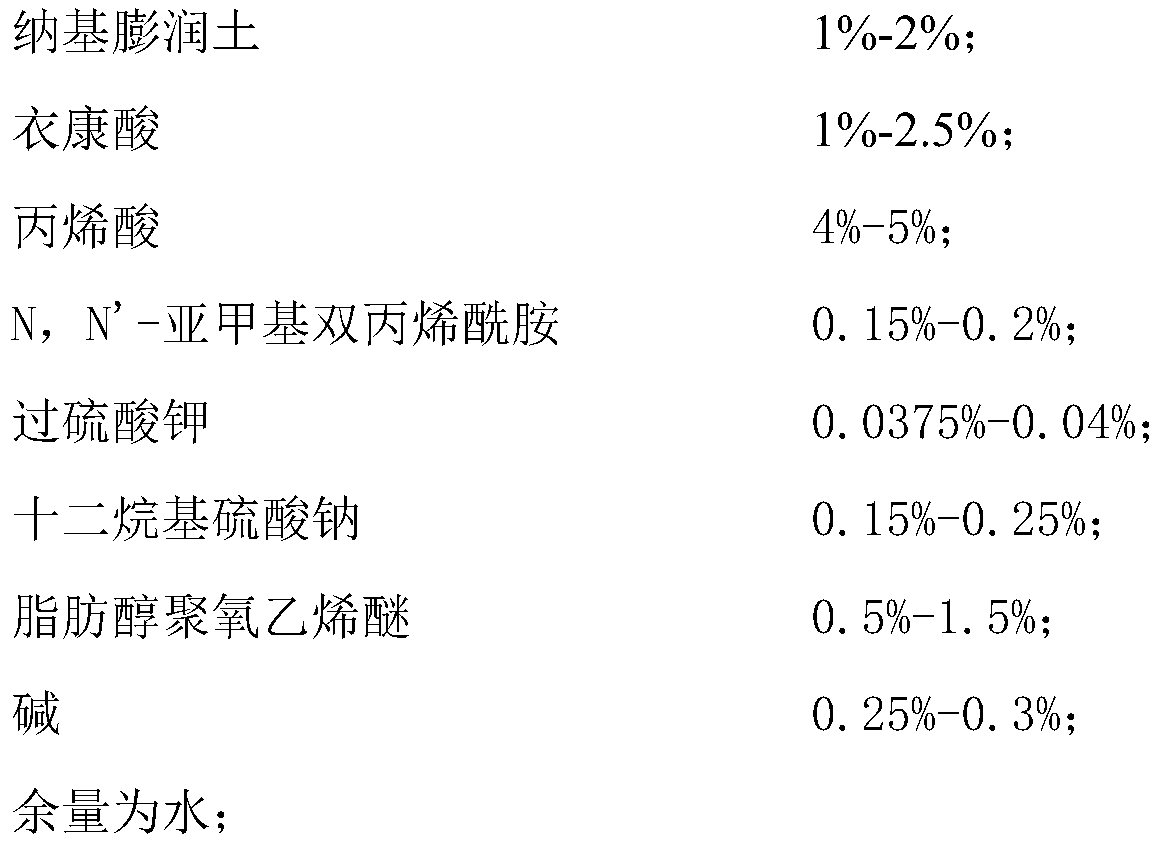

Moistening bonding type dust-control graft modification inhibitor and preparation method thereof

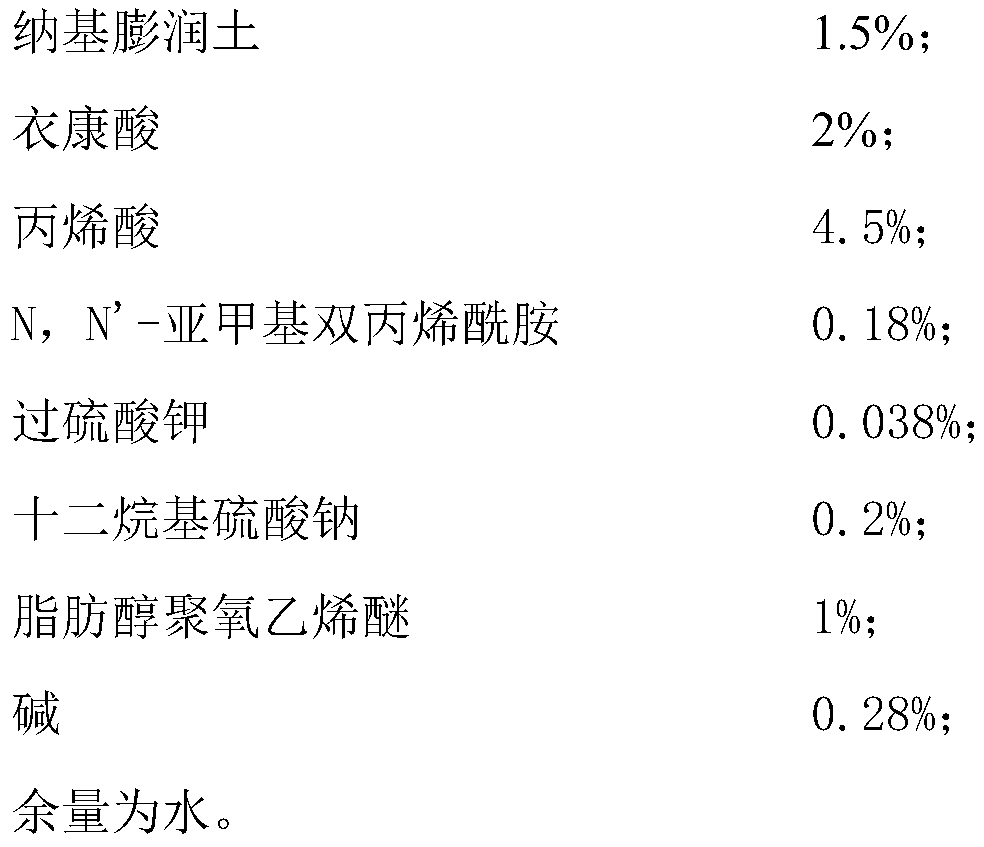

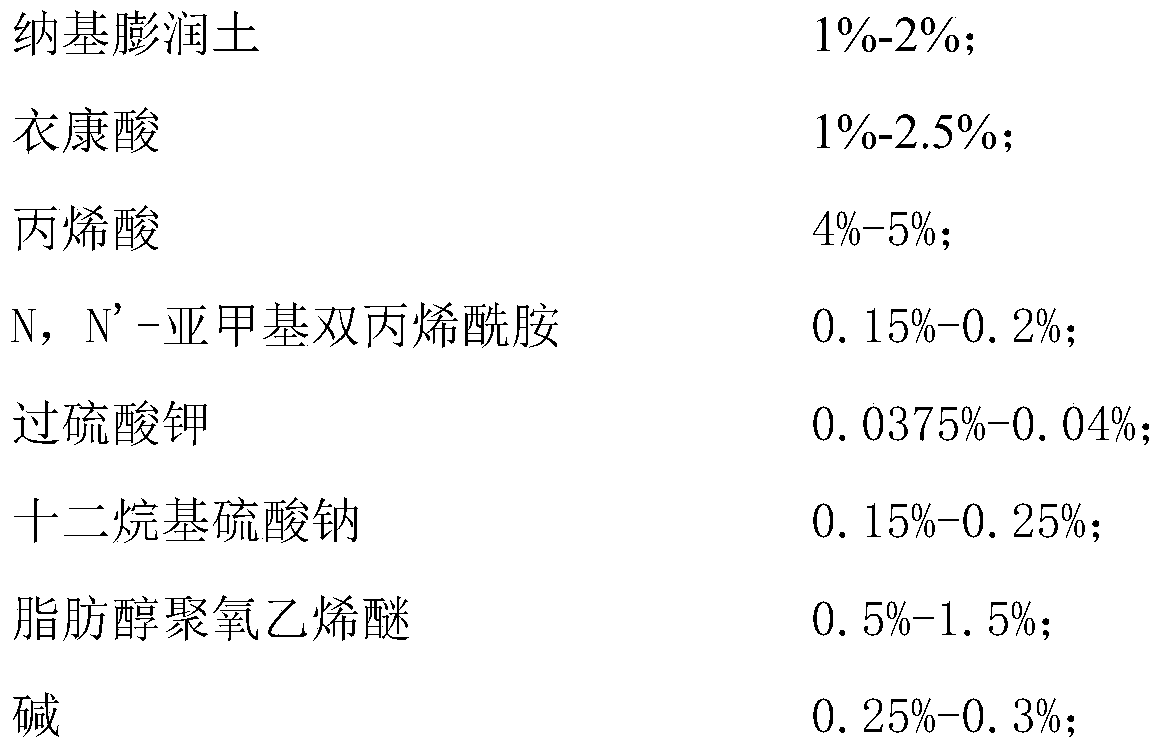

ActiveCN110172331AImproved wet adhesionIncrease viscosityOther chemical processesDust controlPotassium peroxodisulfate

The invention discloses a moistening bonding type dust-control graft modification inhibitor and a preparation method thereof, and relates to the technical field of dust depressors and preparation thereof. The inhibitor is prepared from, by weight, 1-2% of sodium-based bentonite, 1-2.5% of itaconic acid, 4-5% of acrylic acid, 0.15-0.2% of N,N'-methylene bisacrylamide, 0.0375%-0.04% of potassium peroxodisulfate, 0.15-0.25% of lauryl sodium sulfate, 0.5-1.5% of fatty alcohol-polyoxyethylene ether, 0.25-0.3% of sodium hydroxide and the balance water. The sodium-based bentonite serves as a raw material, the itaconic acid and the acrylic acid serve as monomers, and resin is formed after polymerization and has the functions of thickening and adsorption. The inhibitor can improve the dust suppression efficiency and improve the dust concentration of a working surface in a coal mine.

Owner:SHANDONG UNIV OF SCI & TECH

Water-based quick-drying paint for elevators

InactiveCN105062325AGood compatibilityEasy to passPolyurea/polyurethane coatingsEpoxy resin coatingsEpoxyPolymer science

The invention relates to water-based quick-drying paint for elevators. The paint comprises components in parts by weight as follows: 30-35 parts of oxidation drying type water-based resin, 1-3 parts of a water-based self-crosslinking emulsion, 1-3 parts of a dispersing agent, 1-3 parts of a dryer, 1-5 parts of an anti-rust pigment, 35-45 parts of filler, 1 part of an aid and 10-20 parts of deionized water. Acrylate monomers are adopted to promote the esterification structure of epoxy ester, transfer of oxygen is facilitated, meanwhile, the rigidity of the resin is improved by the aid of hard acrylate monomers, and the hardness and the drying speed of the resin are increased; the water-based self-crosslinking emulsion which is good in water resistance at the initial stage is used, due to the principle that substances of the same natures are compatible, the acrylate monomers in the epoxy ester promote the compatibility of the water-based self-crosslinking emulsion with the resin, and the initial-stage water resistance of the resin is reinforced and enhanced in the resin film forming process, so that a paint film has good initial-stage coolant resistance and good wet adhesion.

Owner:HUZHOU HUJIE PAINT CO LTD

Process for producing a multilayer coating

InactiveUS20100266758A1Improve adhesionImprove cohesionLayered productsLaminationWater basedCross-link

The invention relates to a process for the multilayer coating of substrates, in particular vehicle bodies and vehicle body parts, comprising the steps:1. applying a filler layer of a filler coating composition onto an optionally pre-coated substrate, 2. applying a base coat layer of a water-based base coat coating composition containing color-imparting and / or special effect-imparting pigments onto the filler layer, 3. applying a clear coat layer of a transparent clear coat coating composition onto the base coat layer and 4. curing the clear coat layer, optionally together with the filler layer and / or the base coat layer, wherein the filler coating composition being an organic solvent-based coating composition comprising:A) at least one binder with functional groups containing active hydrogen,B) at least one polyisocyanate cross-linking agent with free isocyanate groups andC) at least one epoxy-functional silane of the general Formula (I):X denoting the residues with m being 1-4, or epoxy cyclohexyl,R1, R2, R3 mutually independently meaning identical or different organic residues with 1 to 30 carbon atoms per molecule, providing that at least one of the residues is an alkoxy group with 1 to 4 carbon atoms andn is 2, 3 or 4.

Owner:AXALTA COATING SYST IP CO LLC

Two-component waterborne graphene epoxy zinc-rich coating and preparation method thereof

InactiveCN109880479ALow application costReduce drynessAnti-corrosive paintsEpoxy resin coatingsEpoxyIron powder

The invention relates to the field of coatings, and discloses a double-component waterborne graphene epoxy zinc-rich coating. The coating comprises a component A capable of being cured into a film anda component B containing a curing agent, wherein the component A is prepared from the following raw materials in parts by weight: 40-50 parts of epoxy resin emulsion, 1-2 parts of expanded graphite,20-40 parts of deionized water, 1-2 parts of dispersing agent, 0.5-1 wt% of silane coupling agent, 0.2-0.5 part of defoaming agent, 10-20 parts of talcum powder, 5-10 parts of precipitated barium sulfate and 0.1-0.3 part of neutralizer; the component B comprises 10-20 parts of curing agent, 50-70 parts of zinc powder, 10-20 parts of ferrophosphorus powder, 1-4 parts of anti-settling agent and 5-10parts of film forming auxiliary agent; and the component B is prepared from the following raw materials in parts by weight: 10-20 parts of curing agent, 50-70 parts of zinc powder, 10-20 parts of ferrophosphorus powder, 1-4 parts of anti-settling agent and 5-10 parts of film forming auxiliary agent. The coating can meet the use requirement of a steel structure in an outdoor coastal severe environment.

Owner:SHENZHEN GUOCHUANG JIAWEI GRAPHENE TECH CO LTD +1

Elevator fast-drying paint

InactiveCN105001766AGood compatibilityEasy to passPolyurea/polyurethane coatingsEpoxy resin coatingsEpoxyPolymer science

The invention relates to an elevator fast-drying paint comprising the components of, by weight, 30-40 parts of oxidation drying water-based resin, 1-3 parts of water-based self-cross-linking emulsion, 1-3 parts of a dispersing agent, 1-3 parts of a drying agent, 10 parts of an antirust paint, 46-56 parts of a pigment and filler, and 1 part of an auxiliary agent. The esterified structure of epoxy ester is promoted with an acrylate monomer, such that oxygen delivery is promoted. The hard monomer acrylate facilitates the improvement of resin rigidity, such that resin hardness and drying speed are improved. With the water-based self-cross-linking emulsion with good early-stage water resistance, and with a miscibility principle, the acrylate monomer in the epoxy ester promotes the compatibility between the water-based self-cross-linking emulsion and resin, and resin early-stage water resistance is reinforced and improved during a resin film-forming process. Therefore, an obtained paint film has good early-stage coolant resistance and good wet adhesion.

Owner:HUZHOU HUJIE PAINT CO LTD

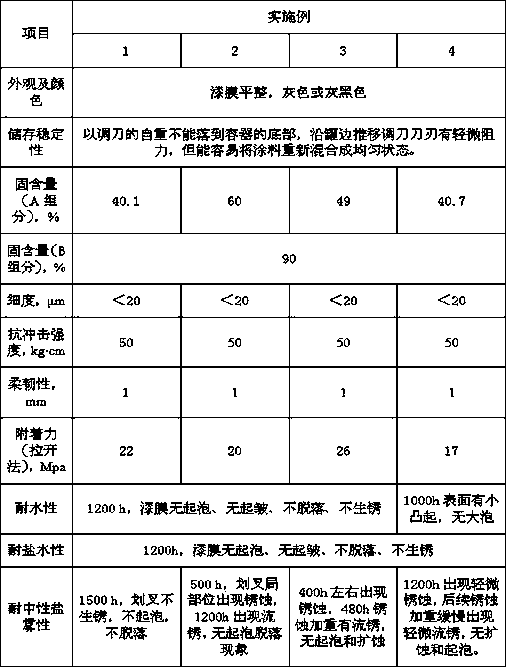

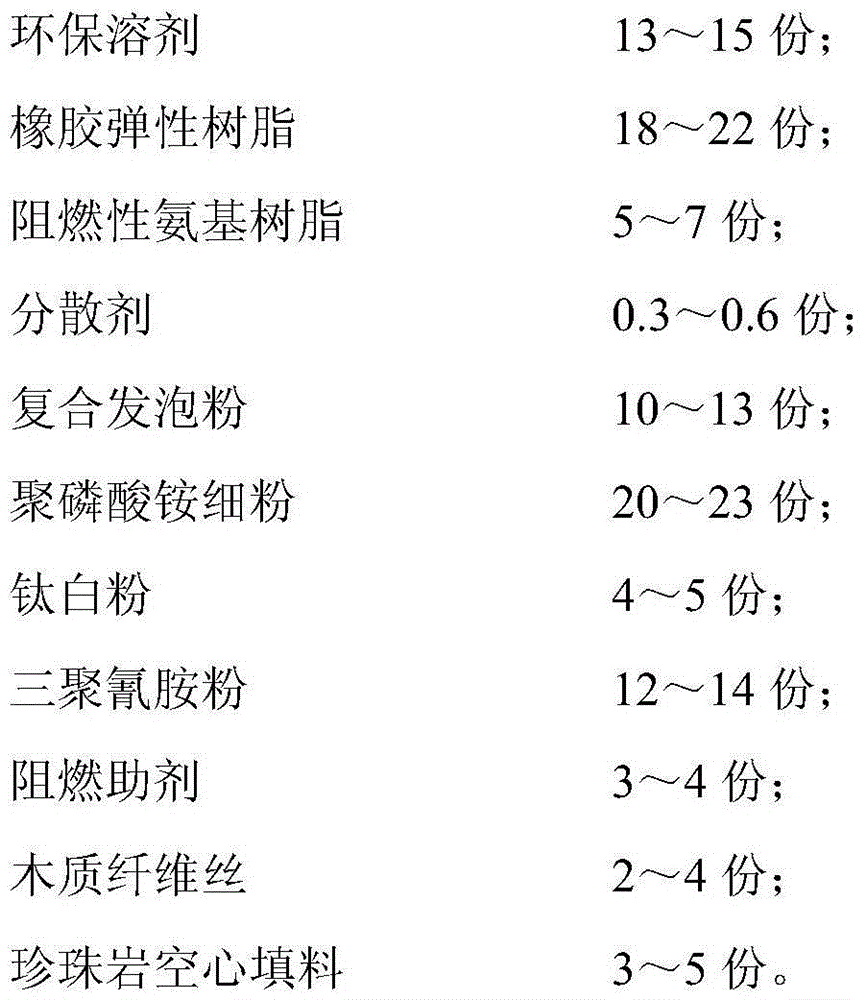

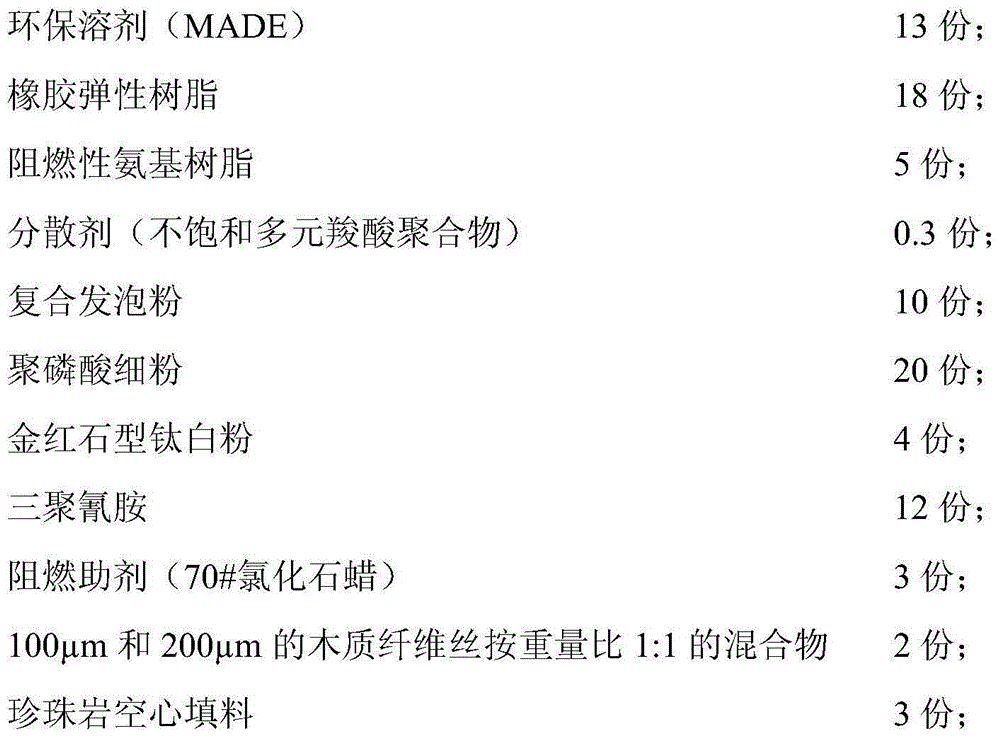

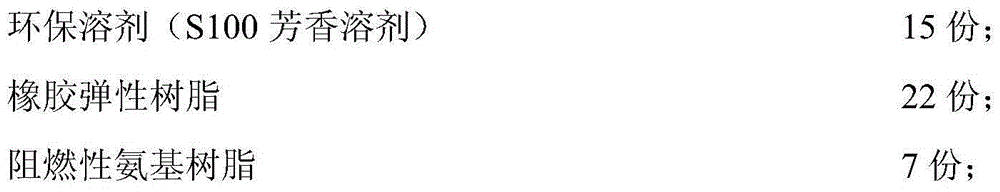

Outdoor elastic fireproof paint and preparation method thereof

ActiveCN104449186AIncrease elasticityImproved wet adhesionFireproof paintsLignin material coatingsFiberWeather resistance

The invention relates to an outdoor elastic fireproof paint and a preparation method thereof. The outdoor elastic fireproof paint comprises the following components: an environment-friendly solvent, rubber elastic resin, flame-retardant amino resin, a dispersant, compound foam powder, fine ammonium polyphosphate powder, titanium pigment, melamine powder, a flame retardant aid, wood cellosilk and hollow perlite fillers. By mixing and matching the rubber elastic resin with the flame-retardant amino resin, the outdoor elastic fireproof paint has ultrahigh water resistance and excellent wet adhesion, weather resistance, elasticity and tensile strength, the condition that the construction is canceled because of raining is reduced, a coating cannot be damaged by the washing of rainwater, and the limitation of construction conditions is avoided; by imitating an actual construction process and a long-term raining condition, the paint is brushed three times continuously to obtain a paint coat with the thickness of 900 microns, and the paint coat which is not completely dried cannot be damaged after being washed by rainwater uninterruptedly for five days and five nights; the paint also has chemical resistance, so that the outdoor use and the durability are guaranteed, and the service life of the outdoor elastic fireproof paint is long.

Owner:WUXI HUHUANG PAINT

Water-based adhesive primer and preparation method thereof

InactiveCN110791170AGood attachment environmentImproved wet adhesionAnti-corrosive paintsEpoxy resin coatingsEmulsionFirming agent

The invention discloses a water-based adhesive primer and a preparation method thereof. The water-based adhesive primer comprises a component A and a component B, wherein the component A is prepared from a water-based modified epoxy emulsion, a color filler, mica powder, an anti-rust pigment, a coalescing agent, an auxiliary agent and water; and the component B comprises a waterborne epoxy curingagent. Compared with the prior art, the water-based adhesive primer disclosed by the invention has an activation period equivalent to that of oil-based primer, is good in salt spray resistance and isenvironment-friendly; and the existing production and engineering construction rhythm of customers is not influenced; the preparation method provided by the invention is simple in process, manual construction cost of customers is reduced greatly, and the preparation method is suitable for industrial mass production.

Owner:德爱威建设工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com