Method for improving surface energy of aluminum plate by using plasma

A plasma and aluminum plate technology, which is used in the preparation of plasma, printing surface, and device for coating liquid on the surface, etc. The effect of improving adhesion and increasing wetting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0064] Raw materials: ordinary aluminum plate (surface corrosion, anodized aluminum grain plate);

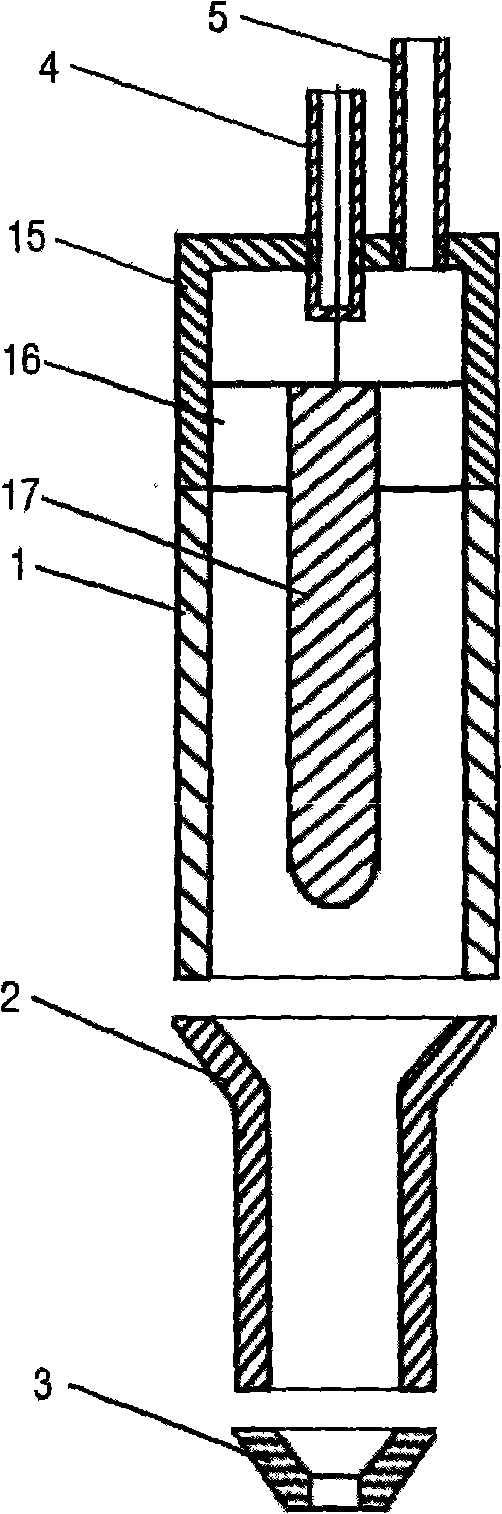

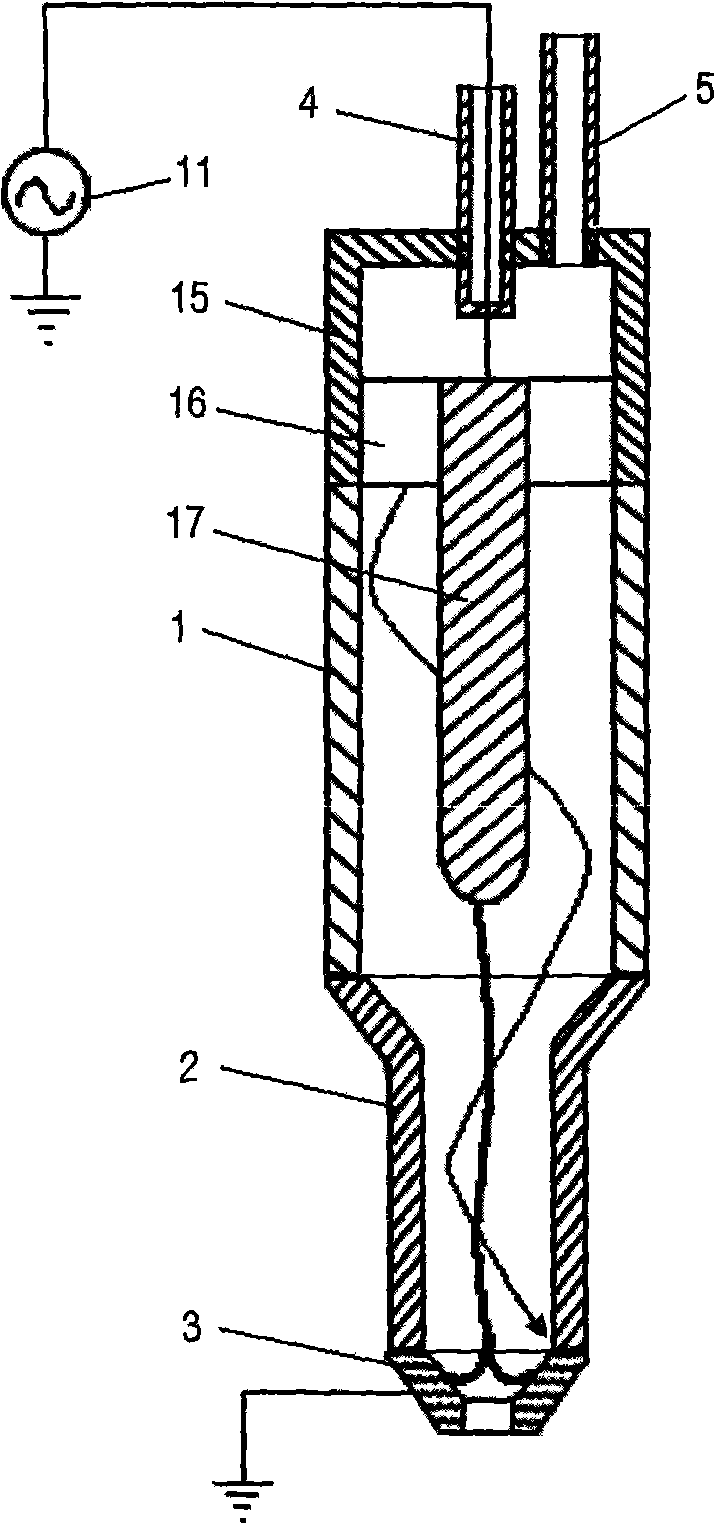

[0065] Equipment used: special power supply 11 for arc plasma (low voltage and high current), such as figure 2 The plasma gun 1 shown;

[0066] Processing process: spray the jet on the surface of the processed aluminum plate in a scanning manner, and use the jet area (the distance from the nozzle 3 to be less than L) to process (refer to Figure 15 );

[0067] Then inkjet or coating process can be carried out. Inkjet is the inkjet of sand grain aluminum plate in the process of CTP processing; coating is the undercoating or coating of photosensitive glue in the production process of traditional PS and CTP plate.

[0068] For the effect of ordinary aluminum plate samples before and after treatment, see Figure 17 and Figure 18 , Figure 17 Shown is the test diagram of the contact angle a of deionized water droplets 8 on the surface of the untreated sample, a is about 67°. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com