Anti-corrosion primer emulsion and preparation method thereof

An anti-corrosion primer and emulsion technology, applied in anti-corrosion coatings, coatings and other directions, can solve the problems of poor anti-corrosion effect, many bubbles, and unenvironmental protection at the construction site, achieve good environmental protection and anti-corrosion performance, increase wet adhesion, and anti-corrosion. outstanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

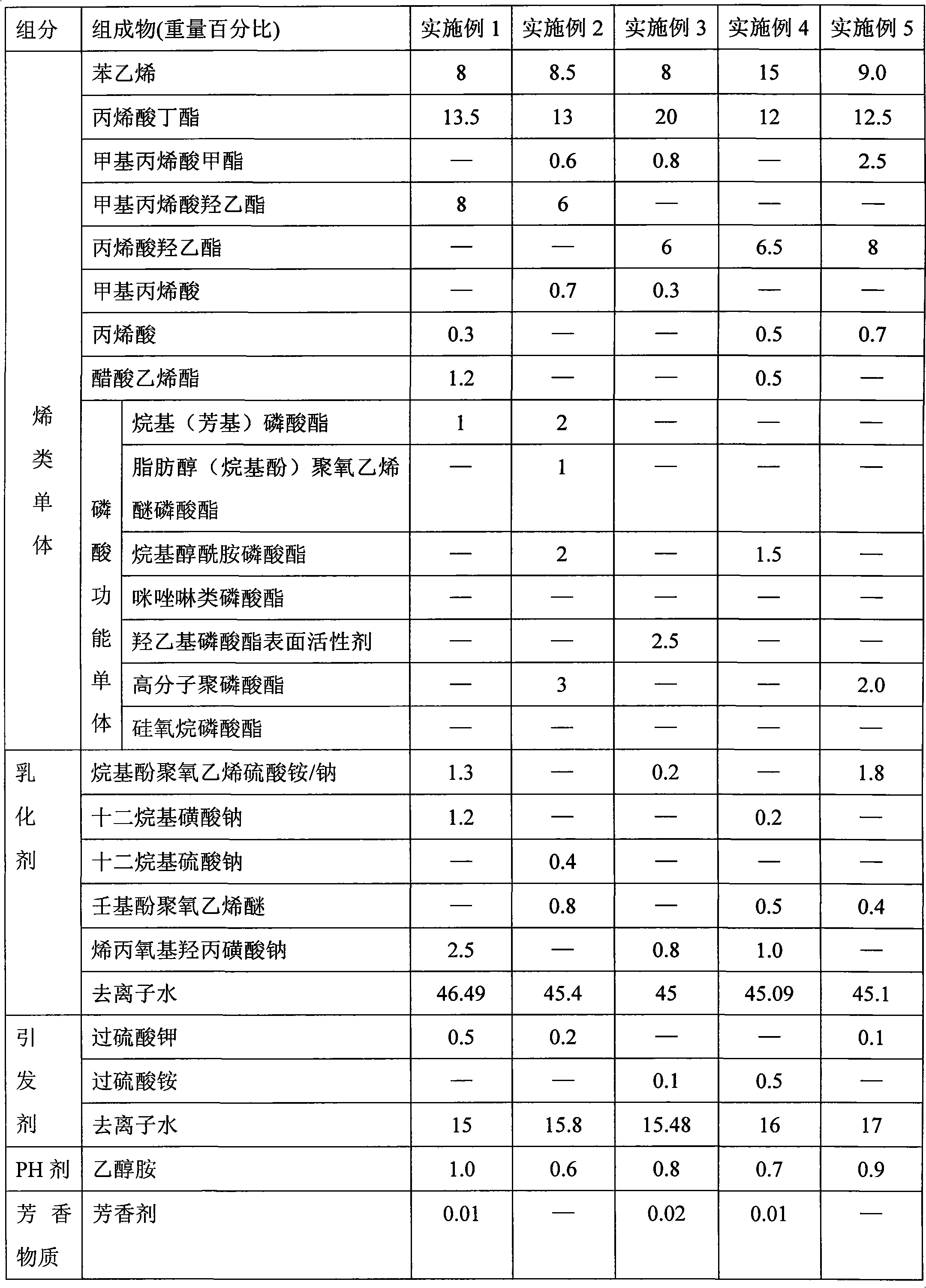

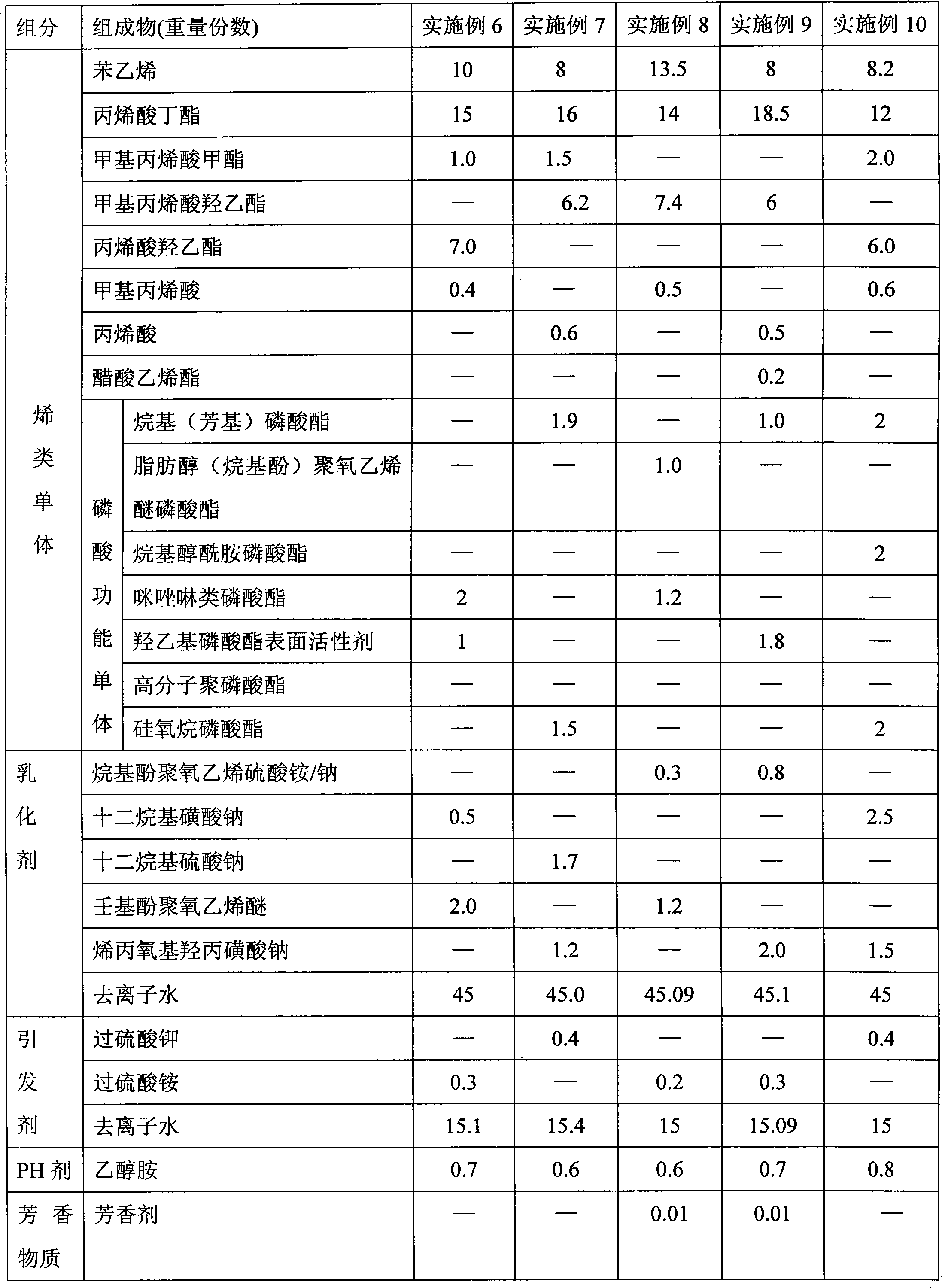

Examples

Embodiment 1

[0033] Embodiment 1 preparation steps:

[0034] a. In a four-necked bottle equipped with a cooler, agitator, a thermometer and a dropping funnel, add the emulsifier components in Example 1 in sequence, stir and emulsify at 45°C for 30 minutes to prepare mixture A;

[0035] b. Weigh in sequence the components of the ethylenic monomer in Example 1 in the monomer-specific storage tank, stir and mix evenly, and make monomer mixture B;

[0036] C, weigh in the initiator component in the embodiment 1 in the initiator special storage tank, stir and mix uniformly, make mixture C;

[0037] d. Add 4% by weight of monomer mixture B to the reaction kettle in step a, and stir at 80°C for 15 minutes;

[0038] e. Add 20% by weight of mixture C to the reaction kettle in step a, and stir at 80° C. for 30 minutes to make a seed emulsion;

[0039] f. Add the remaining monomer mixture B and mixture C to the reaction kettle dropwise, wherein the mixture C is added dropwise 5 minutes later than t...

Embodiment 2

[0041] Embodiment 2 preparation steps:

[0042] a. Add each component of the emulsifier in Example 2 to a four-neck bottle equipped with a cooler, agitator, thermometer, and dropping funnel, and stir and emulsify at 65°C for 5 minutes to prepare mixture A;

[0043] b. Weigh in sequence the components of the ethylenic monomers in Example 2 in the dedicated storage tank for monomers, stir and mix evenly, and make monomer mixture B;

[0044] C, in the initiator special-purpose storage tank, weigh into the initiator 1 component in embodiment 2, stir and mix, make mixture C;

[0045] d. Add 5% by weight of monomer mixture B to the reaction kettle in step a, and stir at 82°C for 5 minutes;

[0046] e. Add 25% by weight of mixture C to the reaction kettle in step a, and stir at 82°C for 60 minutes to make a seed emulsion;

[0047] f. Add the remaining monomer mixture B and mixture C to the reactor simultaneously and continuously dropwise for 2 hours at 82°C, and keep warm at 88°C f...

Embodiment 3

[0049] Embodiment 3 preparation steps:

[0050] a. Add each component of the emulsifier in Example 3 to a four-neck bottle equipped with a cooler, agitator, thermometer, and dropping funnel, and stir and emulsify at 60°C for 10 minutes to prepare mixture A;

[0051] b. Weigh in turn the components of the ethylenic monomers in Example 3 in the dedicated storage tank for monomers, stir and mix evenly, and make monomer mixture B;

[0052] C, weigh in initiator 3 components in the special storage tank of initiator, stir and mix uniformly, make mixture C;

[0053] d. Add 6% by weight of monomer mixture B to the reaction kettle in step a, and stir at 85° C. for 20 minutes;

[0054] e. Add 30% by weight of mixture C to the reaction kettle in step a, and stir at 85° C. for 40 minutes to make a seed emulsion;

[0055] f. Add the remaining monomer mixture B and mixture C to the reactor simultaneously and continuously dropwise for 2 hours at 85°C, and keep warm at 90°C for 40 minutes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com