High-corrosion resistance acrylate resin and preparation method thereof

An acrylate, high corrosion resistance technology, used in coatings, anti-corrosion coatings, etc., can solve problems such as poor corrosion resistance, and achieve the effects of enhancing adhesion, improving wet adhesion, and improving salt spray resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

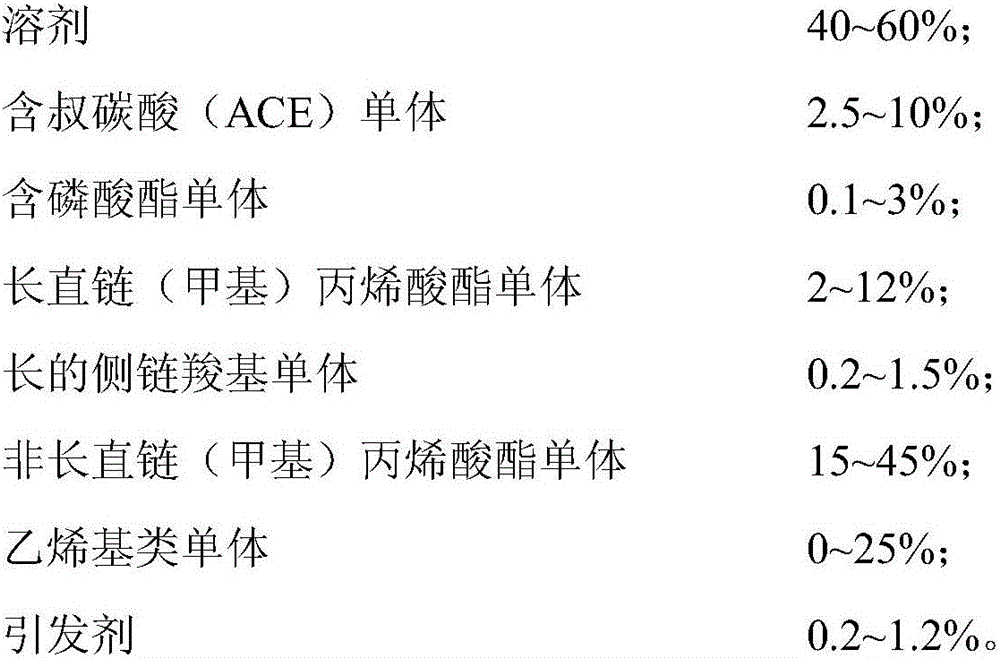

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1, preparation contains tertiary carbonic acid monomer

[0044] Add 770g of glycidyl tert-carbonate, 4g of trinonylphenyl phosphite, and 0.5g of stannous octoate into the reactor, heat to 90°C, keep it warm for 30 minutes, raise the temperature to 108±3°C, and start adding 227g of methyl The mixture of acrylic acid and 0.1g p-hydroxyanisole was added dropwise at a controlled constant speed, and the drop was completed in about 1 hour. After dripping, keep warm for 2 to 3 hours and measure the acid value. If the acid value is higher than 5mgKOH / g, the temperature is raised to 120°C until the acid value is lower than 5mgKOH / g, and the reaction is terminated to obtain a product containing tertiary acid (ACE) monomer.

[0045] The ACE monomer prepared in Example 1 is a mixture, including the following two main structures:

[0046] Structure I:

[0047] Structure II:

[0048] where: R 1 with R 2 is an alkyl group, R 1 with R 2 The sum of the total numbe...

Embodiment 2

[0049] Embodiment 2, preparation acrylate resin

[0050]Put 200g of xylene into the reactor, blow nitrogen, stir and raise the temperature to 132°C, start to drop 128g of butyl methacrylate, 160g of methyl methacrylate, 40g of octadecyl methacrylate, and 60g of Example 1 to obtain The mixture of monomer ACE, 4g β-acryloyloxypropionic acid, 8g PAM200 and 4g di-tert-butyl peroxide was added dropwise at a controlled rate, and the mixture was dropped in about 3 hours. After keeping warm for 1 hour, add 0.4g Di-tert-butyl peroxide was kept warm for 2 hours, cooled to 80° C., diluted by adding 200 g of xylene, stirred and dispersed to obtain a colorless and transparent acrylate resin.

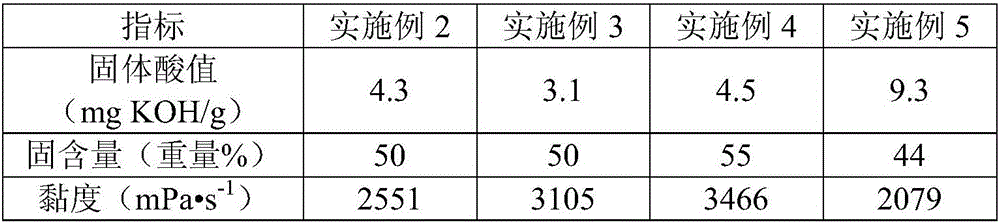

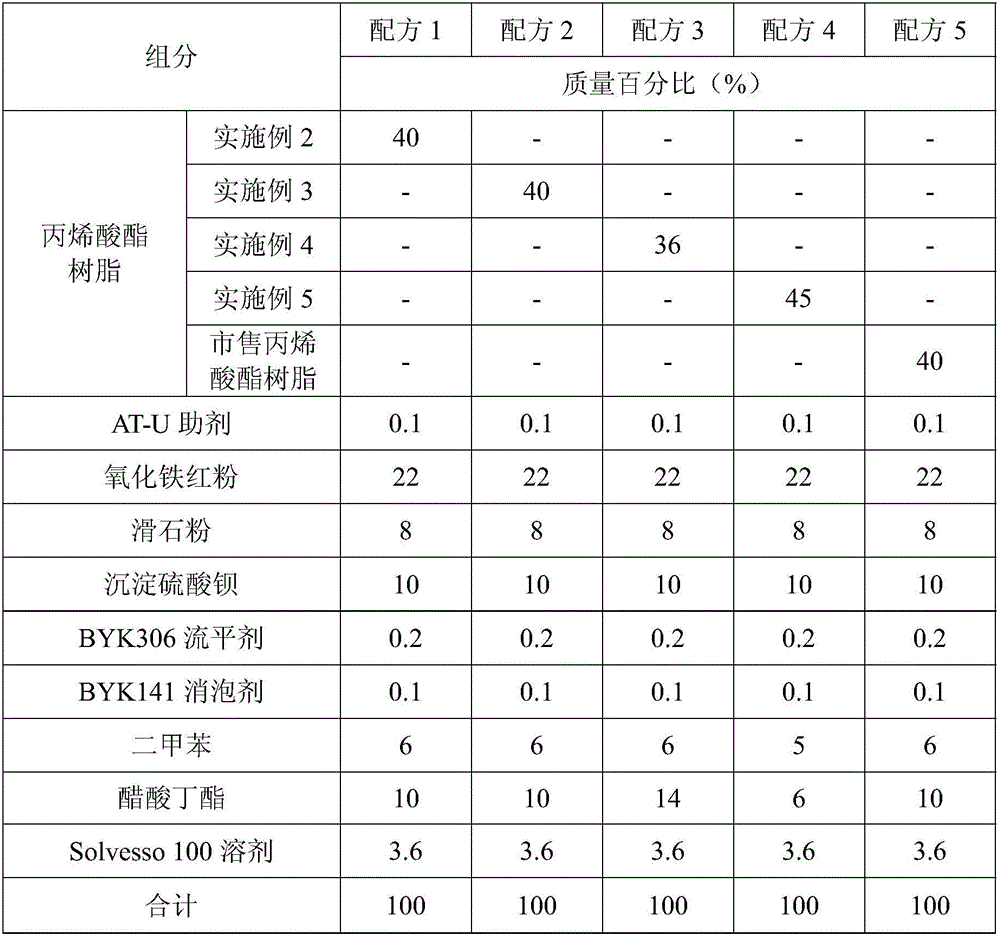

[0051] The performance parameters of the prepared acrylate resin were detected, as shown in Table 1.

Embodiment 3

[0052] Embodiment 3, preparation acrylate resin

[0053] Add 200g of xylene into the reactor, blow nitrogen, stir and raise the temperature to 132°C, start to drop 168g of styrene, 65.6g of butyl methacrylate, 80g of methyl methacrylate, 40g of lauryl methacrylate, 40g The mixture of monomer ACE, 2.4g β-acryloyloxypropionic acid, 4g PAM200 and 2.4g di-tert-butyl peroxide prepared in Example 1 was added dropwise at a controlled rate, and the mixture was dripped in about 3 hours, and kept warm for 1 After 1 hour, add 0.4 g of di-tert-butyl peroxide, keep warm for 2.5 hours, cool down to 80° C., add 200 g of xylene for dilution, stir and disperse to obtain a colorless and transparent acrylate resin.

[0054] The performance parameters of the prepared acrylate resin were detected, as shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com