Waterborne two-component zinc-rich special epoxy curing agent and preparation method thereof

An epoxy curing agent, water-based two-component technology, applied in the direction of epoxy resin coatings, coatings, anti-corrosion coatings, etc. Flash corrosion and other problems, achieve good flexibility and reaction rate, good wet adhesion, and improve the effect of protection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. Preparation of epoxy-terminated polymer

[0040] The formula is as follows:

[0041] Substance name mass, parts by mass PEG1000 210 Epoxy 828 (Shell) 160 potassium persulfate 1

[0042] Preparation:

[0043] Add PEG1000 and epoxy resin 828 into the reaction kettle, raise the temperature to 80°C under nitrogen atmosphere, and keep the temperature until the material becomes transparent; then add potassium persulfate dropwise to raise the temperature to 170°C, keep the temperature for 2 hours, and measure the theoretical epoxy value. When the epoxy value is qualified (epoxy value: 0.04-0.06), the temperature is lowered to obtain the epoxy-terminated polymer and put into a sealed and clean tank for later use.

[0044] 2. Prepare the first curing agent

[0045] The formula is as follows:

[0046]

[0047]

[0048] Preparation:

[0049] Add polyetheramine D-400 and tetrahydrophthalic anhydride to the reaction kettle, and keep wa...

Embodiment 2

[0057] 1. Preparation of epoxy-terminated polymer

[0058] The formula is as follows:

[0059] Substance name mass, parts by mass PEG2000 410 Bisphenol F epoxy resin 180 boron trifluoride 1

[0060] Preparation:

[0061] Add PEG2000 and bisphenol F epoxy resin into the reaction kettle, raise the temperature to 80°C under nitrogen atmosphere, and keep the temperature until the material becomes transparent; then add boron trifluoride to raise the temperature to 180°C, keep the temperature for 2 hours, measure the theoretical epoxy value. When the epoxy value is qualified (epoxy value: 0.04-0.06), the temperature is lowered to obtain an epoxy-terminated polymer, which is put into a sealed and clean tank for later use.

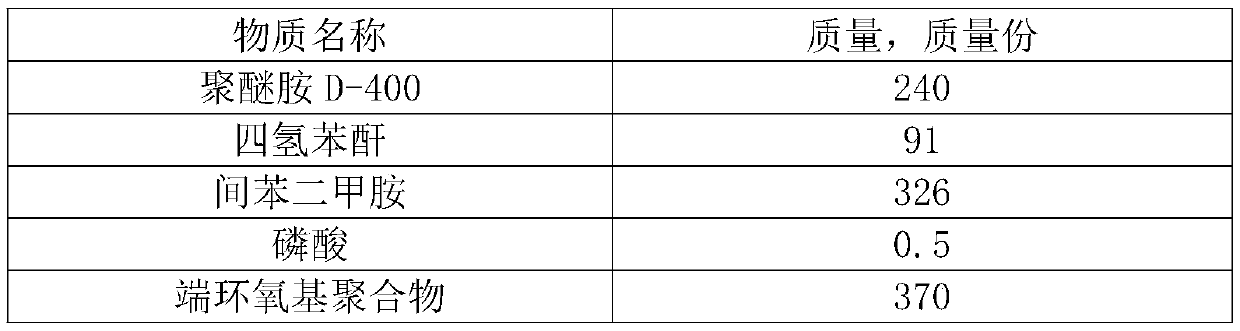

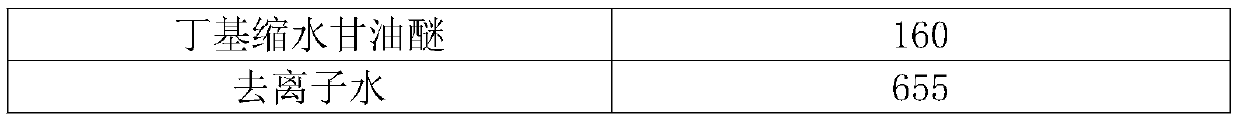

[0062] 2. Prepare the first curing agent

[0063] The formula is as follows:

[0064] Substance name mass, parts by mass Polyetheramine M-1000 240 Hexahydrophthalic anhydride 91 m-xylylenediamine 3...

Embodiment 3

[0074] 1. Preparation of epoxy-terminated polymer

[0075] The formula is as follows:

[0076] Substance name mass, parts by mass PEG1000 210 Epoxy 828 (Shell) 160 potassium persulfate 1

[0077] Preparation:

[0078] Add PEG1000 and epoxy resin 828 into the reaction kettle, raise the temperature to 80°C under nitrogen atmosphere, and keep the temperature until the material becomes transparent; then add potassium persulfate dropwise to raise the temperature to 170°C, keep the temperature for 2 hours, and measure the theoretical epoxy value. When the epoxy value is qualified (epoxy value: 0.03-0.04), the temperature is lowered to obtain the epoxy-terminated polymer and put into a sealed and clean tank for later use.

[0079] 2. Prepare the first curing agent

[0080] The formula is as follows:

[0081] Substance name mass, parts by mass Polyetheramine D-400 240 tetrahydrophthalic anhydride 91 m-xylylenediamine 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com