Two-component waterborne graphene epoxy zinc-rich coating and preparation method thereof

A technology of zinc-rich alkene epoxy and a production method, which is applied in the field of coatings and achieves the effects of reducing drying procedures, reducing application costs, and having good isolation and shielding effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

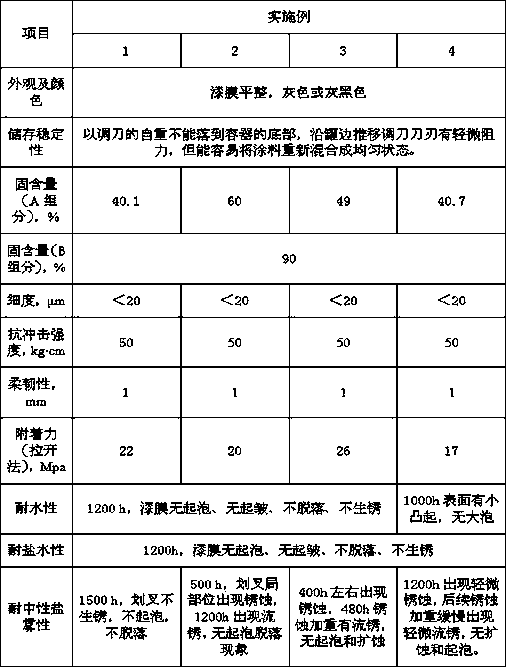

Examples

Embodiment 1

[0056] A two-component water-based graphene heavy-duty anti-corrosion coating, the A component includes the following raw materials in parts by weight, 1.0 parts of expanded graphite, 40 parts of epoxy resin emulsion, 1 part of dispersant, 1 part of coupling agent, defoaming 0.5 parts of neutralizing agent AMP-95, 10 parts of talcum powder, 5 parts of precipitated barium sulfate, 41.3 parts of deionized water.

[0057] The preparation method of the coating A component is as follows:

[0058] (1) Put the resin emulsion, dispersant, coupling agent, defoamer, neutralizer, and deionized water of component A in a mixing container, and stir with an electric disperser at a speed of 1500 r / min. The stirring time was 20 min to obtain a resin dispersion.

[0059] (2) Then add the formulated amount of expanded graphite, continue to stir at a speed of 1500 r / min, and stir for 10 min to obtain a graphite resin slurry.

[0060] (3) The graphite slurry was sheared at a high speed of 5000 r...

Embodiment 2

[0069] A two-component water-based graphene heavy-duty anti-corrosion coating, the A component includes the following raw materials in parts by weight, 1.5 parts of mechanically exfoliated graphene, 60 parts of epoxy resin emulsion, 1.5 parts of dispersant, 1.5 parts of coupling agent, 0.75 parts of defoaming agent, 0.3 parts of neutralizing agent AMP-95, 15 parts of talcum powder, 7.5 parts of precipitated barium sulfate, and 11.95 parts of deionized water.

[0070] The preparation method of the coating A component is as follows:

[0071] (1) Put the resin emulsion, dispersant, coupling agent, defoamer, neutralizer, and deionized water of component A in a mixing container, and stir with an electric disperser at a speed of 1500 r / min. The stirring time was 20 min to obtain a resin dispersion.

[0072] (2) Then add the formulated amount of graphene, continue to stir, the rotation speed is 1500 r / min, and the stirring time is 10 min to obtain the graphene resin slurry.

[0073...

Embodiment 3

[0081] A two-component water-based graphene heavy-duty anti-corrosion coating, the A component includes the following raw materials in parts by weight, 0.75 parts of expanded graphite, 50 parts of epoxy resin emulsion, 1.25 parts of dispersant, 1.25 parts of coupling agent, defoaming 0.6 parts of neutralizer, 0.25 parts of neutralizing agent AMP-95, 12.5 parts of talcum powder, 6.25 parts of precipitated barium sulfate, and 27.15 parts of deionized water.

[0082] The preparation method of the coating A component is as follows:

[0083] (1) Put the resin emulsion, dispersant, coupling agent, defoamer, neutralizer, and deionized water of component A in a mixing container, and stir with an electric disperser at a speed of 1500 r / min. The stirring time was 20 min to obtain a resin dispersion.

[0084] (2) Then add the formulated amount of expanded graphite, continue to stir at a speed of 1500 r / min, and stir for 10 min to obtain a graphite resin slurry.

[0085] (3) The graphit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com