Moistening bonding type dust-control graft modification inhibitor and preparation method thereof

A technology of graft modification and inhibitor, which is applied in the field of dust suppressant and its preparation, can solve the problems of re-pollution, loss of dust suppression effect, easy cracking of consolidated layer, etc., and achieve good dust control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

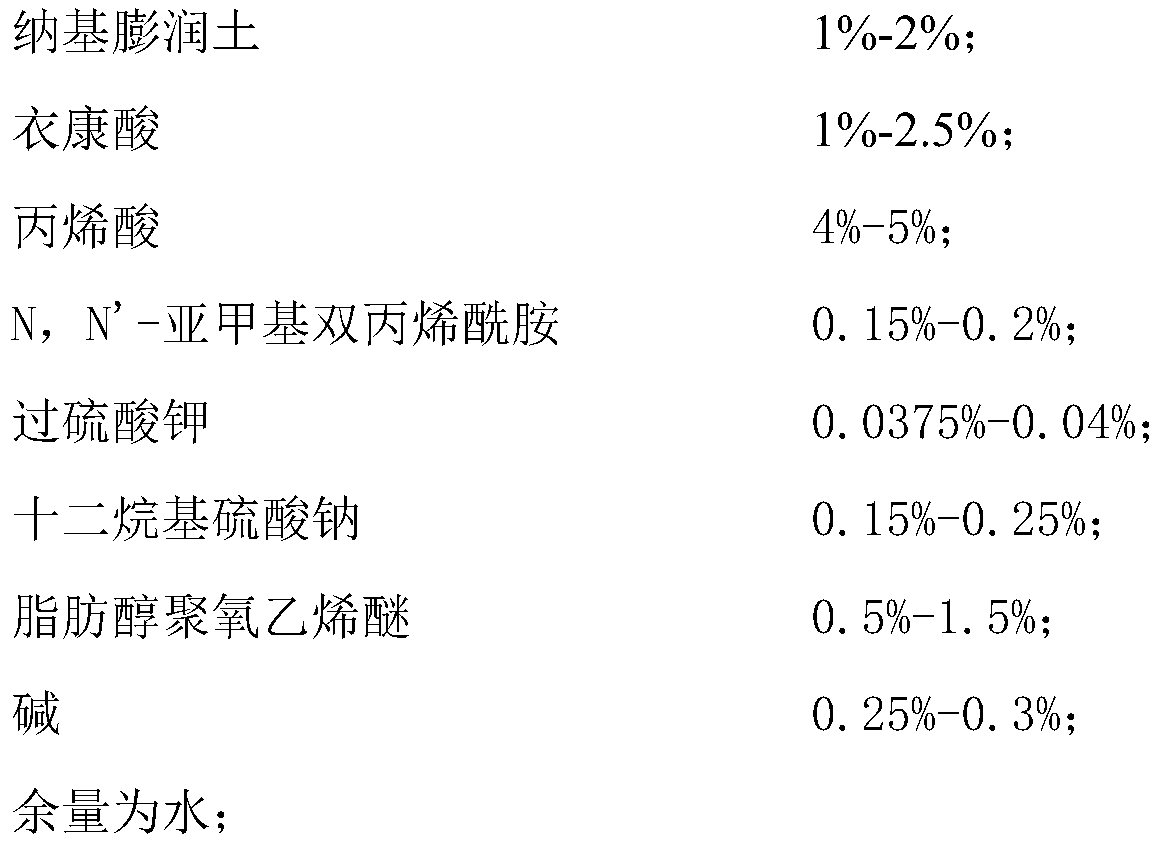

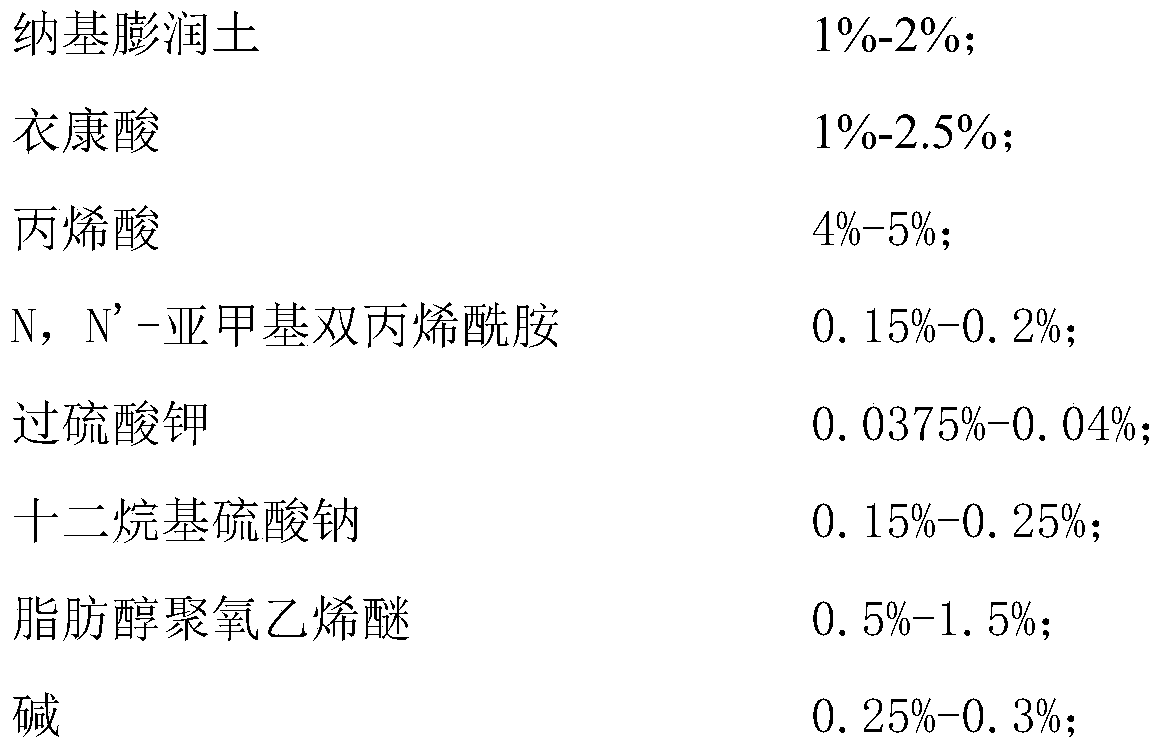

[0039] Adopt the weight proportion of combination one raw material.

[0040] Preparation:

[0041] The first step is to neutralize itaconic acid and acrylic acid with alkali respectively, and the neutralization degree is 70%. The neutralized itaconic acid and acrylic acid are mixed together, put into a three-necked flask, and put Stir in a magnetic heating pot, the pH value is 6, and stir to obtain a mixed solution 1;

[0042] In the second step, potassium persulfate is prepared into a solution with a certain mass fraction, and part of it is added to the mixed solution 1 of the first step to obtain the mixed solution 2. The temperature of the reactor is controlled to rise to 70°C, and after stirring for 1.5 hours, the obtained intermediate product IA-co-AA;

[0043] The third step is to dissolve the nano-based bentonite to obtain a bentonite solution, and add the intermediate product IA-co-AA obtained in the second step to the bentonite solution to obtain a mixed solution th...

Embodiment 2

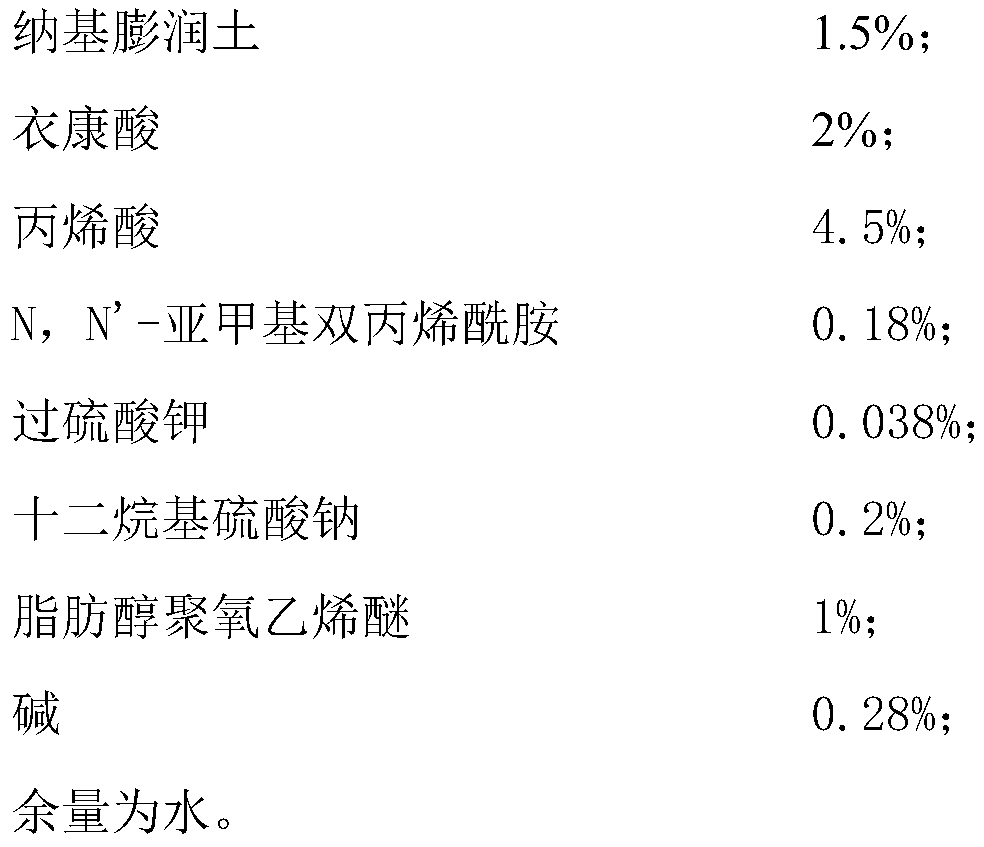

[0045] Adopt the weight proportion of combining two raw materials.

[0046] Preparation:

[0047] The first step is to neutralize itaconic acid and acrylic acid with alkali respectively, and the neutralization degree is 70%. The neutralized itaconic acid and acrylic acid are mixed together, put into a three-necked flask, and put Stir in a magnetic heating pot, the pH is 8, and stir to obtain a mixed solution 1;

[0048]In the second step, potassium persulfate is prepared into a solution with a certain mass fraction, and part of it is added to the mixed solution 1 of the first step to obtain the mixed solution 2. The temperature of the reactor is controlled to rise to 70°C, and after stirring for 1.5 hours, the obtained intermediate product IA-co-AA;

[0049] The third step, dissolving the nano-based bentonite to obtain a bentonite solution, adding the intermediate product IA-co-AA obtained in the second step to the bentonite solution to obtain a mixed solution three, adding ...

Embodiment 3

[0051] The first step is to neutralize itaconic acid and acrylic acid with alkali respectively, and the neutralization degree is 70%. The neutralized itaconic acid and acrylic acid are mixed together, put into a three-necked flask, and put Stir in a magnetic heating pot, the pH value is 6, and stir to obtain a mixed solution 1;

[0052] In the second step, potassium persulfate is prepared into a solution with a certain mass fraction, and part of it is added to the mixed solution 1 of the first step to obtain the mixed solution 2. The temperature of the reactor is controlled to rise to 70°C, and after stirring for 1.5 hours, the obtained intermediate product IA-co-AA;

[0053] The third step, dissolving the nano-based bentonite to obtain a bentonite solution, adding the intermediate product IA-co-AA obtained in the second step to the bentonite solution to obtain a mixed solution three, adding the remaining potassium persulfate solution to the mixed solution three, To obtain mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com