Water-based adhesive primer and preparation method thereof

A water-based bonding and primer technology, used in primers, coatings, anti-corrosion coatings, etc., can solve problems such as non-compliance with environmental protection requirements, large amount of thinner, and large pollution, reducing labor construction costs and achieving excellent wet adhesion. The effect of focus and salt spray resistance is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

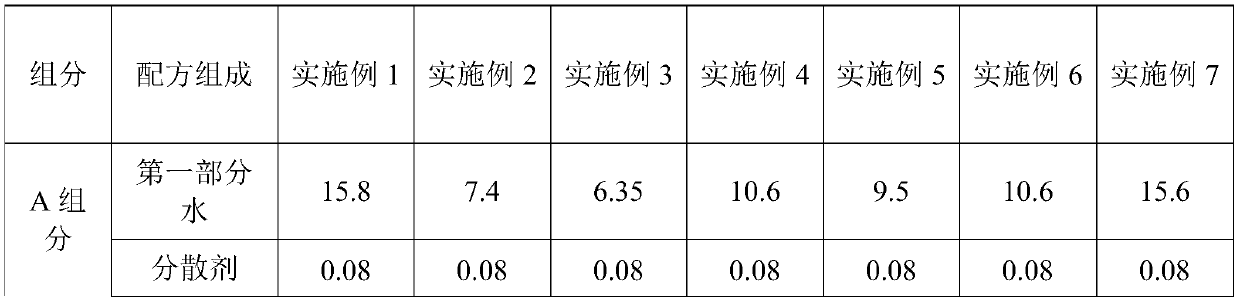

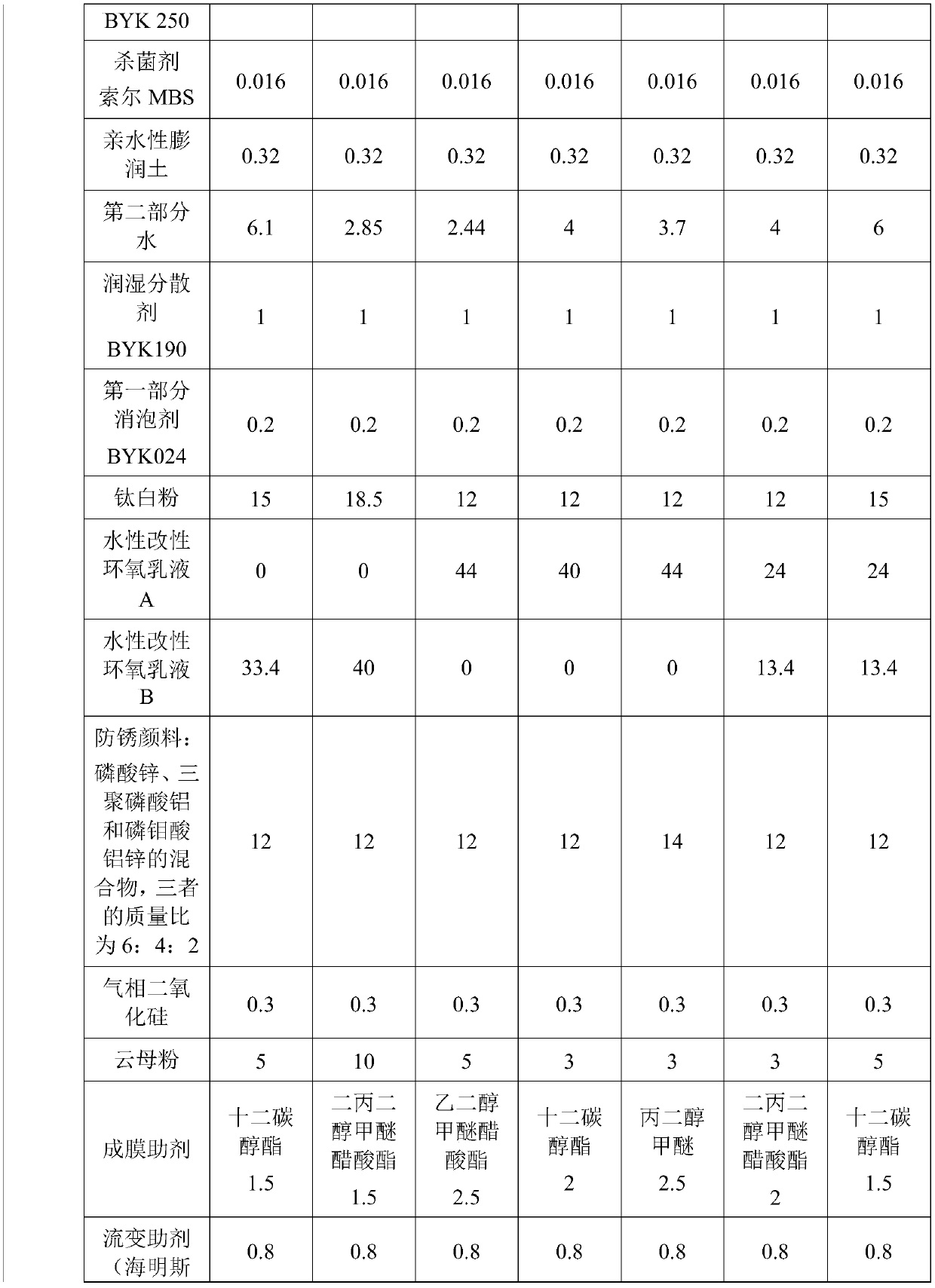

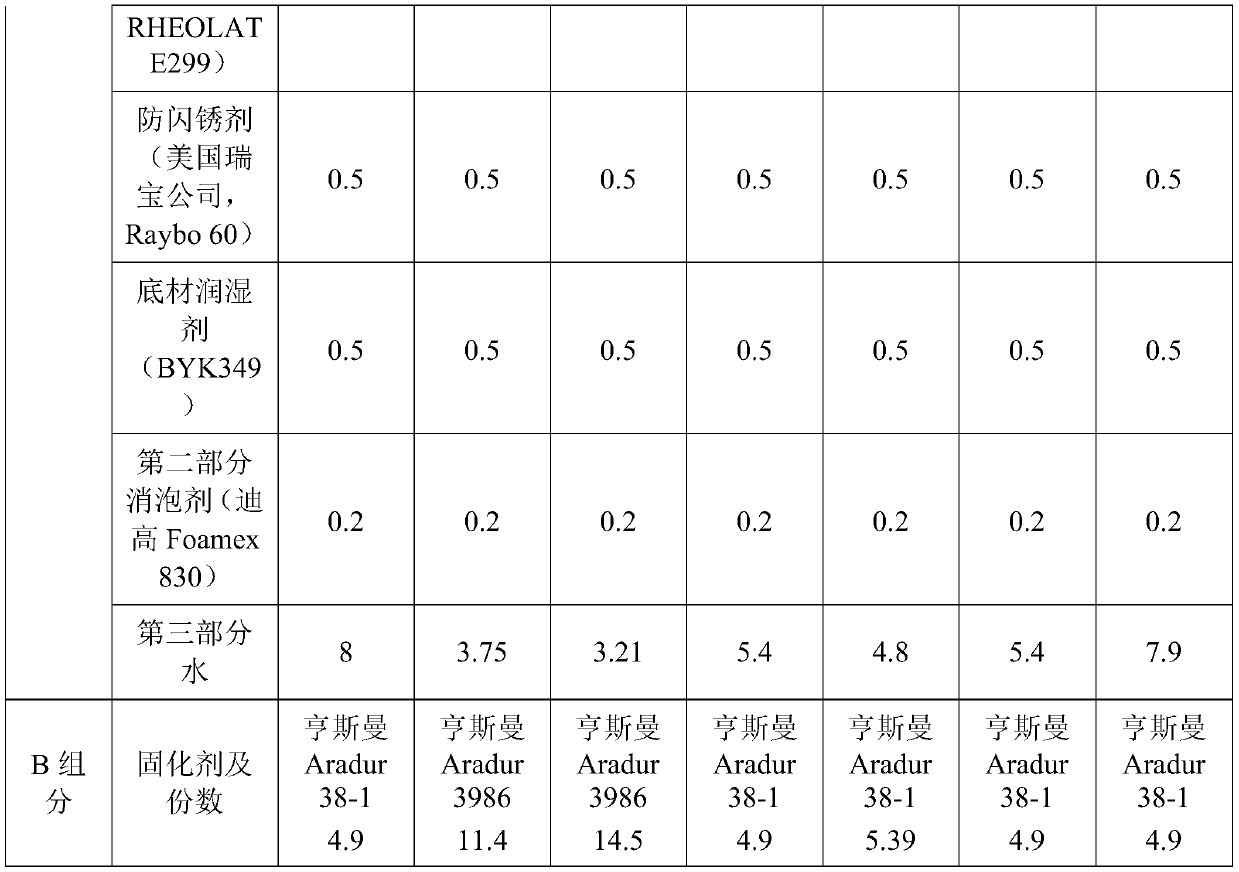

[0067] The preparation method of water-based adhesive primer includes the following steps:

[0068] 1) Mix the first part of water, dispersant, and bactericide evenly, then add hydrophilic bentonite and mix evenly to obtain bentonite slurry, which is a viscous jelly-like liquid;

[0069] In step 1), control the mixing speed to 800rpm and the time to 35min;

[0070] 2) The bentonite slurry obtained in step 1) is evenly mixed with the second part of water, wetting and dispersing agent, and the first part of defoaming agent, adding titanium dioxide, anti-rust pigment, fumed silica and mica powder, grinding and dispersing to particle size Is 30μm to obtain filler slurry;

[0071] 3) Mix the filler slurry with the water-based modified epoxy emulsion for 10 minutes, and control the system speed to 600 rpm, and then add film-forming additives, rheological additives, anti-flash rust agents, substrate wetting agents, and the second part to the system Antifoaming agent, reduce the system speed...

Embodiment 8

[0074] The difference from the above step is that in step 2), the dispersion is ground to a fineness of 40 μm.

Embodiment 9

[0076] The difference from the above step is that in step 2), the dispersion and grinding are performed to a fineness of 50 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com