Outdoor elastic fireproof paint and preparation method thereof

A fire-resistant coating and elastic technology, applied in the direction of fire-resistant coatings, lignin coatings, coatings, etc., can solve the problems of fire-resistant coatings that cannot be applied, coating damage, peeling, etc., and achieve the effect of excellent decoration, fine coating, and uniform expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

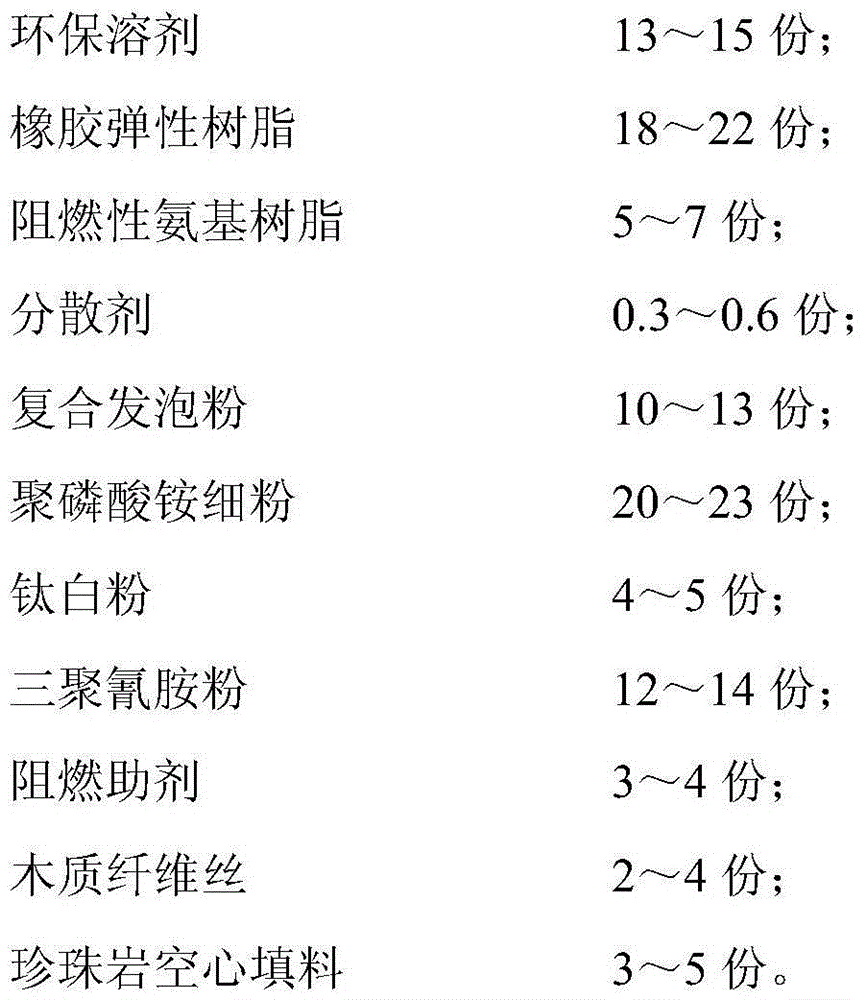

[0048] A kind of fireproof coating, it comprises the component of following parts by weight:

[0049]

[0050] The preparation method of above-mentioned fireproof coating, comprises the steps:

[0051] (1) Add the environmentally friendly solvent, rubber elastic resin, flame retardant amino resin and dispersant in the formulated amount in turn, stir for 10 minutes at 1000 rpm, and mix well;

[0052] (2) Add compound foaming powder, ammonium polyphosphate, titanium dioxide, melamine and flame retardant additives in sequence to the mixed material in step (1), stir at 1000 rpm for 25 minutes, mix well and grind to Fineness≤60μm;

[0053] (3) When the fineness of step (2) reaches the requirement, add perlite hollow filler and wood fiber filaments in turn, stir at 700 rpm for 30 minutes, disperse and stir evenly to obtain.

Embodiment 2

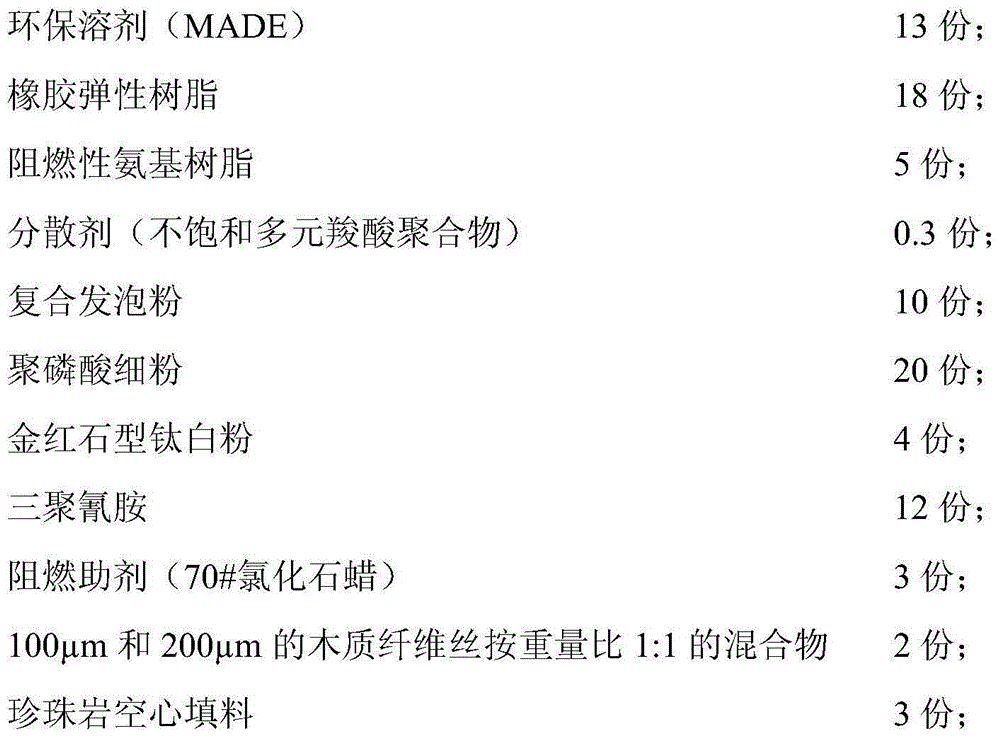

[0055] A kind of fireproof coating, it comprises the component of following parts by weight:

[0056]

[0057]

[0058] The preparation method of above-mentioned fireproof coating, comprises the steps:

[0059] (1) Add the environmentally friendly solvent, rubber elastic resin, flame-retardant amino resin and dispersant in the formula quantity in turn, stir for 5 minutes at 1200 rpm, and mix well;

[0060] (2) Add compound foaming powder, ammonium polyphosphate fine powder, titanium dioxide, melamine and flame retardant additives in sequence to the mixed material in step (1), stir at 1200 rpm for 25min, and mix well Grind to fineness≤60μm;

[0061] (3) When the fineness of step (2) reaches the requirement, add perlite hollow filler and wood fiber filaments in turn, stir at 800 rpm for 25 minutes, disperse and stir evenly to obtain.

Embodiment 3

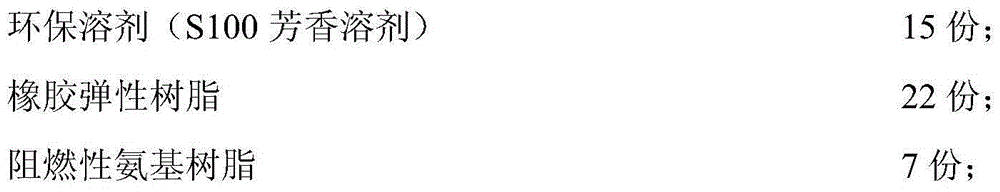

[0063] A kind of fireproof coating, it comprises the component of following parts by weight:

[0064]

[0065] The preparation method of above-mentioned fireproof coating, comprises the steps:

[0066] (1) Add the environmentally friendly solvent, rubber elastic resin, flame retardant amino resin and dispersant in the formulated amount in turn, stir for 8 minutes at 1100 rpm, and mix well;

[0067] (2) Add compound foaming powder, ammonium polyphosphate fine powder, titanium dioxide, melamine powder and flame retardant additives in sequence to the mixed material in step (1), stir at 1100 rpm for 28 minutes, and mix well Grind to fineness≤60μm;

[0068] (3) When the fineness of step (2) reaches the requirement, add perlite hollow filler and wood fiber filaments in turn, stir at 700 rpm for 28 minutes, disperse and stir evenly to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com