Oil stain-resistant and antirust water-based modified acrylic iron red primer and preparation method thereof

A technology of acrylic iron red and water-based acrylic acid, applied in the field of paint making, can solve the problems of incomplete treatment of oil stains on the substrate, poor smooth surface effect, expensive oil stain resistance additives, etc., and achieves good wetting adhesion and frost resistance. Good melting stability and good resistance to substrate oil stains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

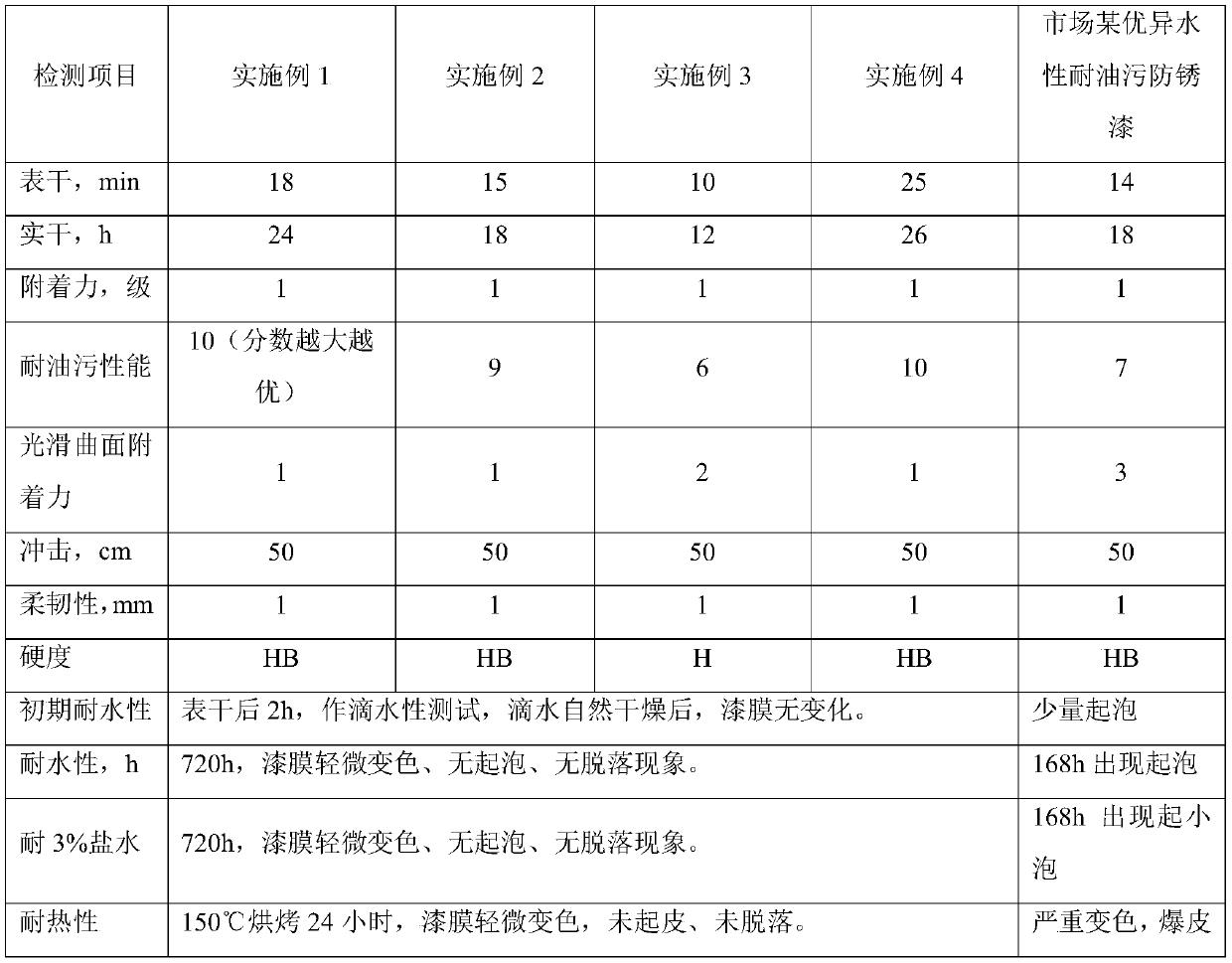

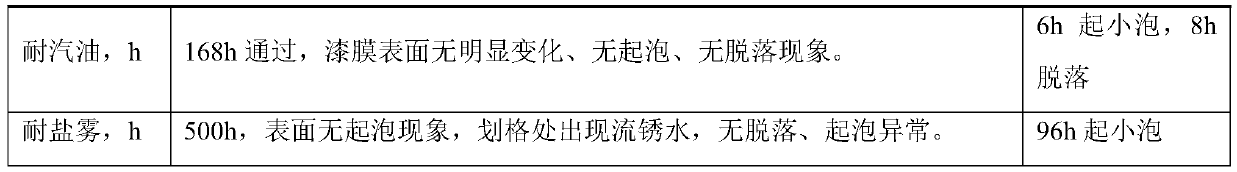

Examples

Embodiment

[0016] 1. Water-based modified acrylic iron red oil-resistant and anti-rust primer

[0017] The raw materials are as follows:

[0018] Water-based acrylic emulsion (0614 Wanhua)

[0019] Waterborne Epoxy Ester Resin (GS-5000B Changzhou Guangshu)

[0020] Film-forming aids (ethylene glycol monobutyl ether, propylene glycol monobutyl ether, dipropylene glycol butyl ether, diethylene glycol butyl ether, polyethylene glycol, diethylene glycol dimethyl ether, n-butanol, etc. above)

[0021] Neutralizer (one or more of N,N-dimethylethanolamine, triethylamine, ammonia water, tetramethylammonium hydroxide, AMP-95, etc.)

[0022] deionized water (homemade)

[0023] Water-based dispersant (ZWD1 Huanqi Chemical)

[0024] Water-based defoamer (BYK-024 BYK)

[0025] Anti-flash rust agent (ZH-55 Jiangsu Shisong)

[0026] Drier (6206 allnex)

[0027] Organic bentonite (DE Hemings)

[0028] Fumed silica (972 Degussa)

[0029] Iron Oxide Red (190D Shuangma New Century)

[0030] Heav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com