Sticky rice wet glue added with emulsion stabilizer and preparation method thereof

An emulsification stabilizer, glutinous rice wet glue technology, applied in the direction of adhesive additives, non-polymer adhesive additives, adhesive types, etc., can solve the problems of poor frost resistance, thickening and hardening during storage, and resistance to Aging is not good and other problems, to achieve the effect of improving anti-aging performance, long shelf life, and delicate appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

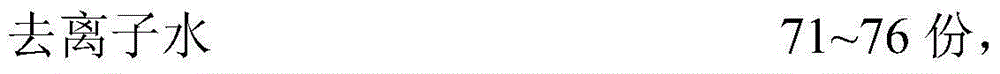

[0038] A glutinous rice wet glue added with an emulsification stabilizer, the formula is as follows:

[0039]

[0040] The preparation method of glutinous rice wet glue:

[0041] ①Preparation of the solution:

[0042] Dissolve sodium hydroxide in deionized water to make a sodium hydroxide solution with a mass concentration of 9%-10%, dissolve glacial acetic acid in deionized water to make a glacial acetic acid solution with a mass concentration of 12.5%-13%, and dissolve calcium propionate Prepare a calcium propionate solution with a mass concentration of 16%-18% in deionized water.

[0043] ② Gelatinization, crosslinking and complexation reactions of raw materials:

[0044] Add the remaining deionized water into the reaction kettle, start stirring, control the stirring speed at 38-42r / min, then add starch, stir and disperse evenly, then add urea and emulsification stabilizer and stir for 15 minutes, then heat up to 30°C to start The sodium hydroxide solution was added d...

Embodiment 2

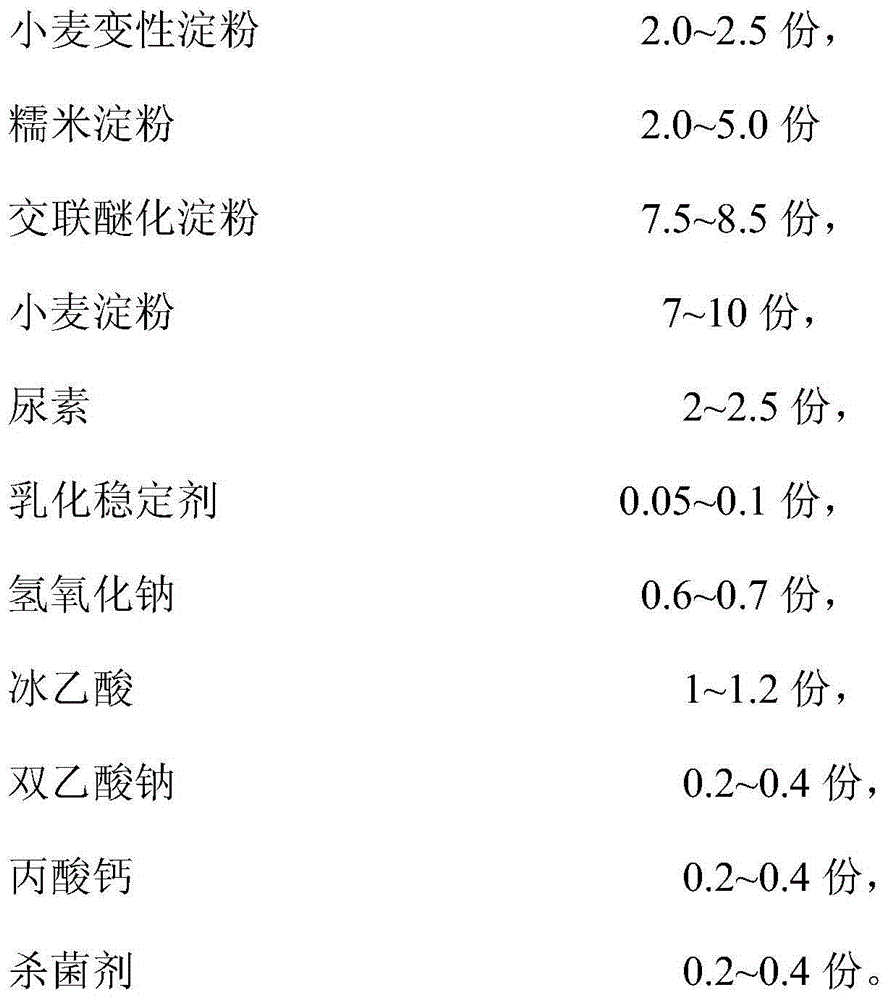

[0046] A kind of glutinous rice wet glue that adds emulsification stabilizer, preparation method is the same as embodiment 1, and formula is as follows:

[0047]

[0048] The preparation method of glutinous rice wet glue:

[0049] ①Preparation of the solution:

[0050] Sodium hydroxide is dissolved in deionized water to make a sodium hydroxide solution with a mass concentration of 9%, glacial acetic acid is dissolved in deionized water to make a glacial acetic acid solution with a mass concentration of 12.5%, and calcium propionate is dissolved in deionized water to make A calcium propionate solution with a mass concentration of 16%.

[0051] ② Gelatinization, crosslinking and complexation reactions of raw materials:

[0052] Add the remaining deionized water into the reaction kettle, start stirring, and control the stirring speed at 40r / min, then add starch, stir and disperse evenly, then add urea and emulsification stabilizer and stir for 15 minutes, then raise the temp...

Embodiment 3

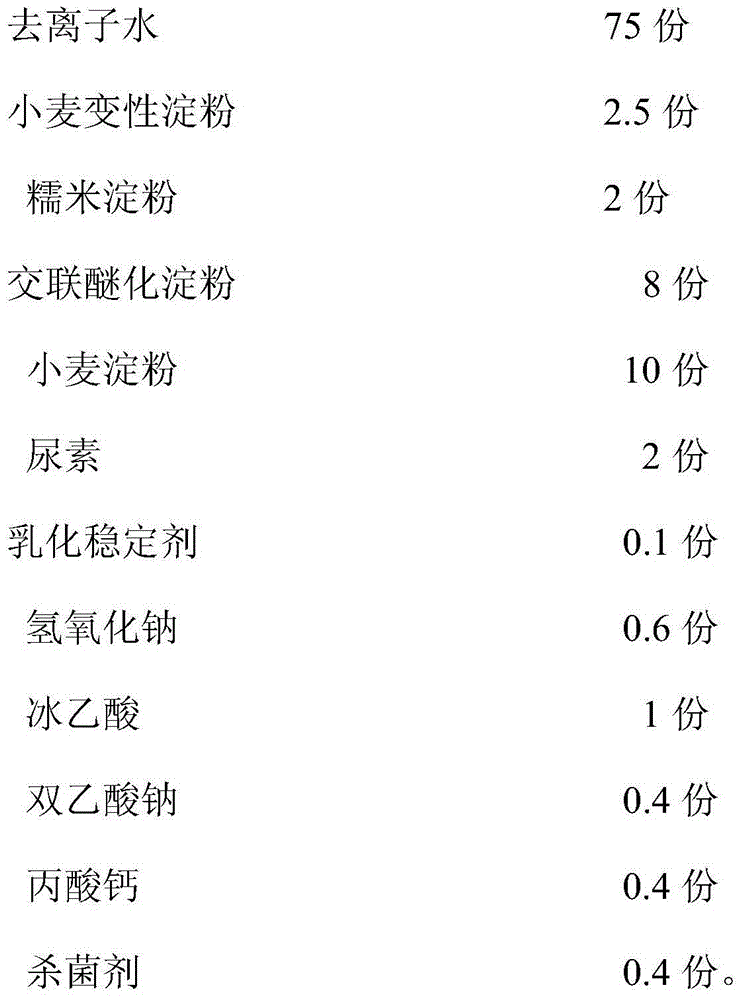

[0054] A kind of glutinous rice wet glue that adds emulsification stabilizer, preparation method is the same as embodiment 1, and formula is as follows:

[0055]

[0056]

[0057] The preparation method of glutinous rice wet glue:

[0058] ①Preparation of the solution:

[0059] Dissolve sodium hydroxide in deionized water to make a sodium hydroxide solution with a mass concentration of 9%-10%, dissolve glacial acetic acid in deionized water to make a glacial acetic acid solution with a mass concentration of 12.5%-13%, and dissolve calcium propionate Prepare a calcium propionate solution with a mass concentration of 16%-18% in deionized water.

[0060] ② Gelatinization, crosslinking and complexation reactions of raw materials:

[0061] Add the remaining deionized water into the reaction kettle, start stirring, and control the stirring speed at 42r / min, then add starch, stir and disperse evenly, then add urea and emulsification stabilizer and stir for 15 minutes, then ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com