Tar-free epoxy resin coating and its preparation method

A technology of epoxy resin coating and epoxy resin liquid, which is applied in the direction of epoxy resin coating, anti-corrosion coating, coating, etc., can solve the problems of poor water resistance, environment and construction personnel hazards, and achieve excellent impact resistance, low cost, Good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

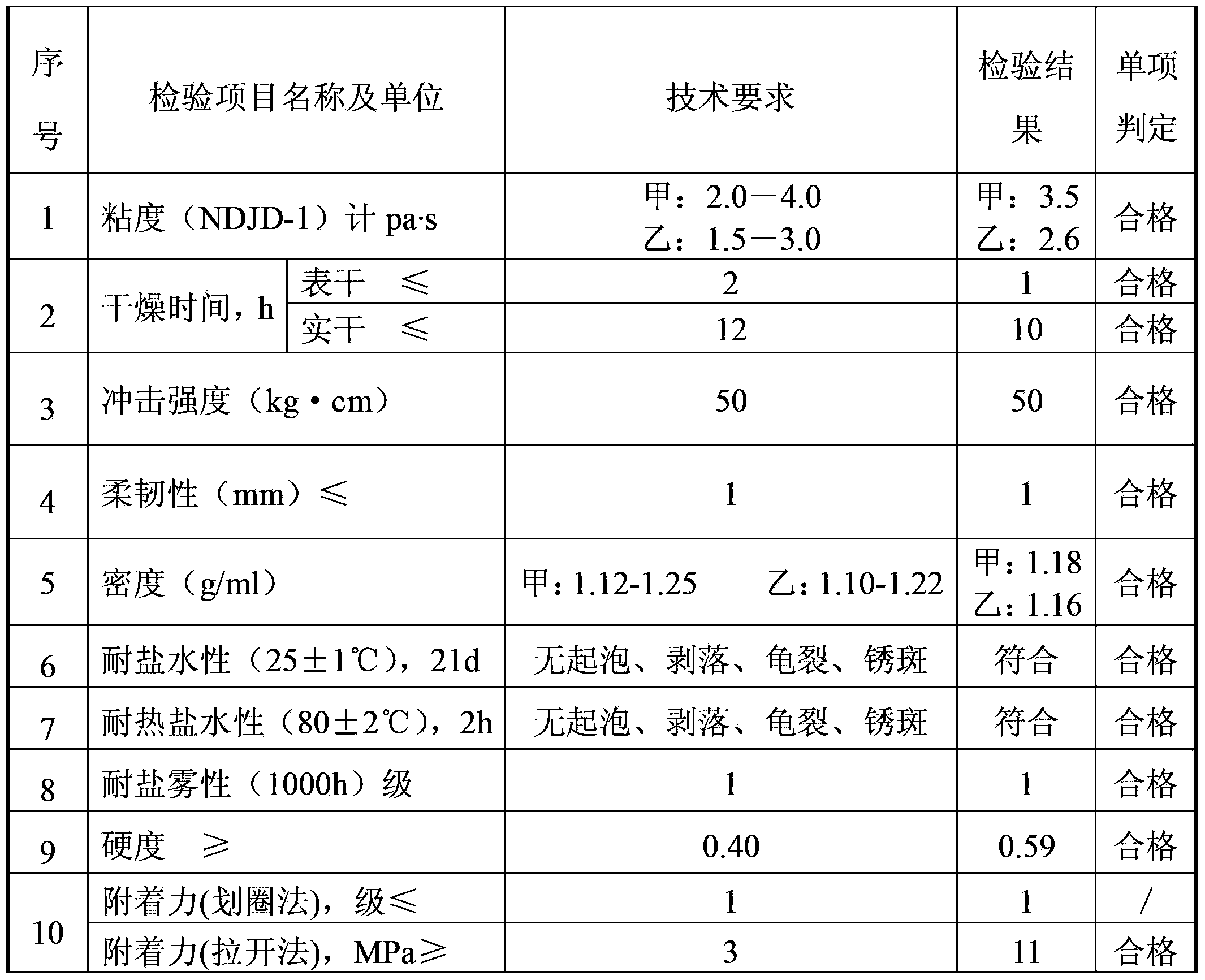

Examples

Embodiment 1

[0048] Described coating comprises A component and B component, and wherein A component comprises the 601 epoxy resin liquid 25wt% of 75wt% by weight fraction, the 210 phenolic resin liquid 10wt% of 50wt%, the petroleum resin liquid 8wt% of 50wt%, Anti-settling agent 5wt%, filler 30wt%, pigment 10wt%, solvent 10wt% and co-solvent 2wt%;

[0049] Component B includes curing agent 50wt%, solvent 50wt% by weight fraction;

[0050] The mass ratio of the A component to the B component is 5:1.

Embodiment 2

[0052] Described coating comprises A component and B component, wherein A component comprises 75wt% 601 epoxy resin liquid 20wt% by weight fraction, 50wt% 210 phenolic resin liquid 4wt%, 50wt% petroleum resin liquid 4wt%, Organobentonite 0.5wt%, fumed silica 0.5wt%, superfine mica powder 50wt%, floating silver powder paste 4wt%, propylene glycol methyl ether 1wt%, xylene 14wt% and industrial ethanol 2wt%;

[0053] The second component comprises 650 polyamide resin 30wt%, propylene glycol methyl ether 20wt% and xylene 50wt% by weight fraction;

[0054] The mass ratio of the A component to the B component is 5:1.

Embodiment 3

[0056] Described coating comprises A component and B component, and wherein A component comprises the 601 epoxy resin liquid 35wt% of 75wt% by weight fraction, the 210 phenolic resin liquid 4wt% of 50wt%, the petroleum resin liquid 12wt% of 50wt%, Organic bentonite 4wt%, fumed silica 0.5wt%, superfine mica powder 30wt%, floating silver powder paste 4wt%, propylene glycol methyl ether 6wt%, xylene 4.2wt% and industrial ethanol 0.3wt%;

[0057] The second component comprises 650 polyamide resin 80wt%, propylene glycol methyl ether 15wt% and xylene 5wt% by weight fraction;

[0058] The mass ratio of the A component to the B component is 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com