Water-based rust-proof primer with rust and preparation method thereof

A technology of anti-rust and primer with rust, applied in anti-corrosion coatings, coatings, etc., can solve the problems of low adhesion to substrates, high molecular weight of vinylidene chloride polymers, and reduced protective performance of paint films

Inactive Publication Date: 2019-09-13

深圳安盾海洋新材料有限公司

View PDF3 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantage is that local organic acid residues on the unevenly rusted surface will reduce the protective performance of the paint film. The vinylidene chloride polymer has a large molecular weight, a high glass transition temperature, and low adhesion to the substrate.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0093] The following are some representative examples of the present invention, but the present invention is not limited to these examples.

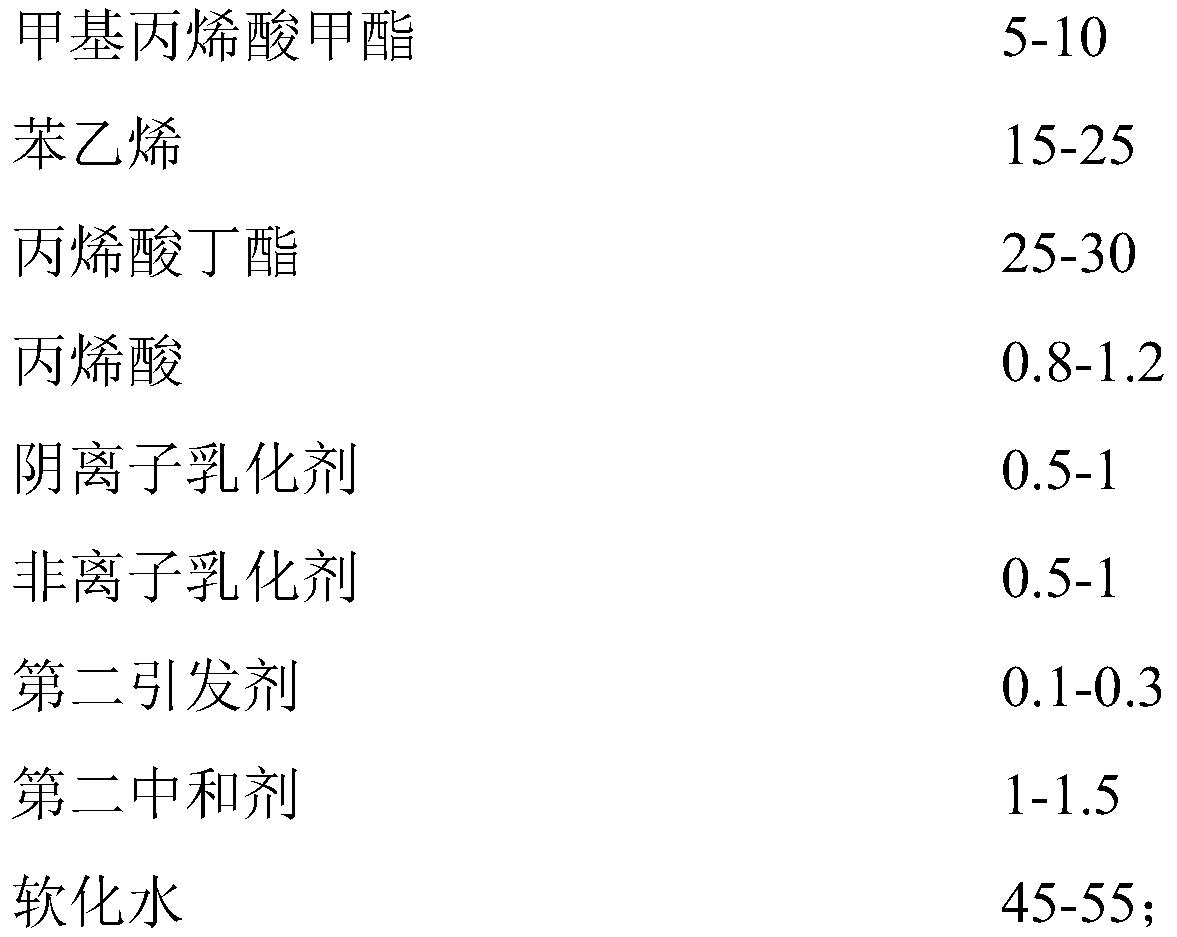

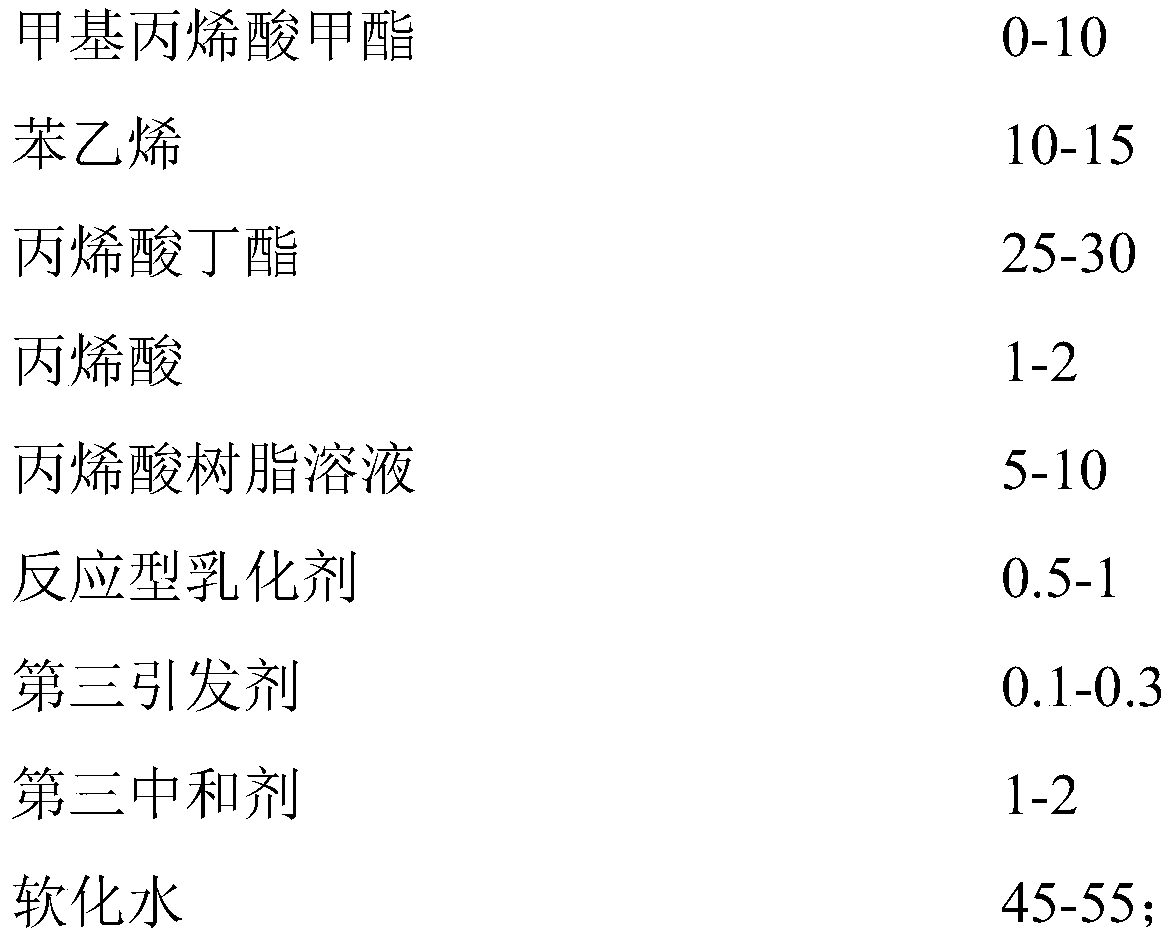

[0094] 1. Synthesis of core-shell structure acrylic emulsion

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

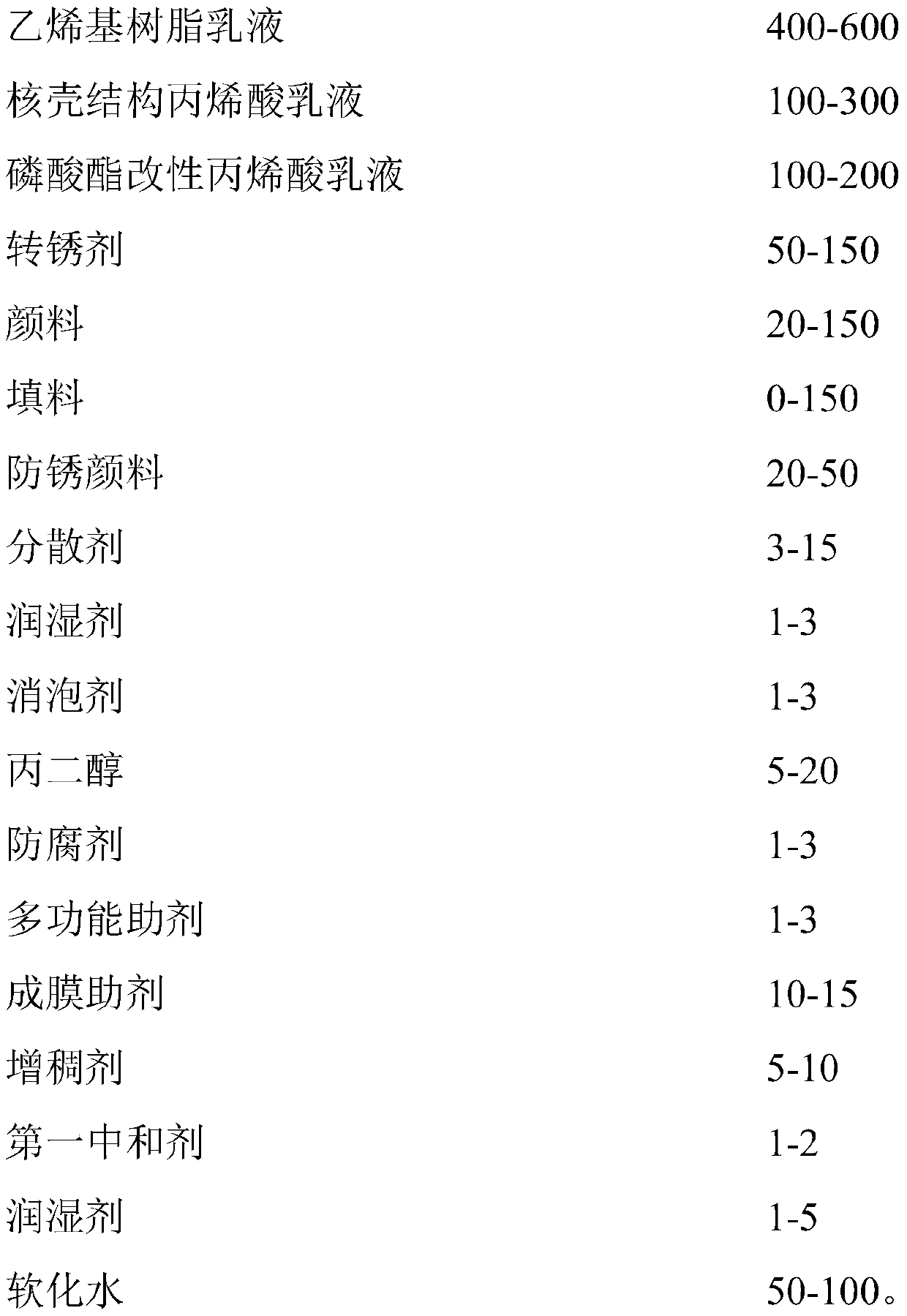

The invention relates to the field of chemical anti-corrosion coatings, particularly to a water-based rust-proof primer with rust and a preparation method thereof. The water-based rust-proof primer with rust uses a vinyl emulsion, a core-shell-structured acrylic emulsion and a phosphate-modified acrylic acid emulsion as base materials. The preparation method comprises the following steps: firstly,selecting the main base material, i.e., the vinyl emulsion; then synthesizing the auxiliary base materials, i.e., the core-shell-structured acrylic resin emulsion and the phosphate-modified acrylic emulsion; and then with the above three emulsions as the base materials, mixing the base materials with a rust conversion agent, an antifreezing agent, a wetting agent, an antifoaming agents and otheradditives to prepare the water-based rust-proof primer with rust. The obtained water-based rust-proof primer with rust is low in VOC content, safe and environment-friendly, convenient to construct, good in compatibility with common anti-corrosion topcoats, good in rust conversion effect, strong in adhesion and long in an antirust period, and has wide application prospects.

Description

technical field [0001] The invention relates to the field of chemical anticorrosion coatings, in particular to a water-based antirust primer with rust and a preparation method thereof. Background technique [0002] The treatment of the substrate has a great influence on the protective performance of the coating. Generally, the coating of anti-corrosion coatings has strict requirements on the treatment of the substrate, and the rust removal level is often required to reach Sa2.5 or St3. When the surface corrosion of the substrate is serious, the derusting work needs to spend a lot of manpower. In order to reduce the workload of rust removal, two approaches are mainly taken. One approach is to use low surface finish coatings, which generally have a lower viscosity to facilitate penetration into the substrate. For example, epoxy primer with low surface treatment, which allows the substrate to remain firmly attached to the scale and old paint film; another way is to apply rust...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D127/22C09D151/00C09D5/08C09D7/61C09D7/65C09D7/63C08F257/02C08F220/18C08F2/22

CPCC08F2/22C08F257/02C08K2003/328C08K2201/014C08L2205/025C08L2205/035C08L2207/53C09D5/08C09D5/084C09D7/61C09D7/63C09D7/65C09D127/22C08L51/003C08L71/02C08K13/02C08K3/32C08K3/34C08K5/053

Inventor 陈庆杨春晖侯佩民

Owner 深圳安盾海洋新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com