Cell cathode and lithium ion cell using the same and their manufacture methods

A lithium-ion battery and negative electrode technology, which is applied in the field of lithium-ion batteries and their preparation, can solve the problems of poor cycle performance of lithium-ion batteries, and achieve the effects of improving cycle performance and enhancing bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

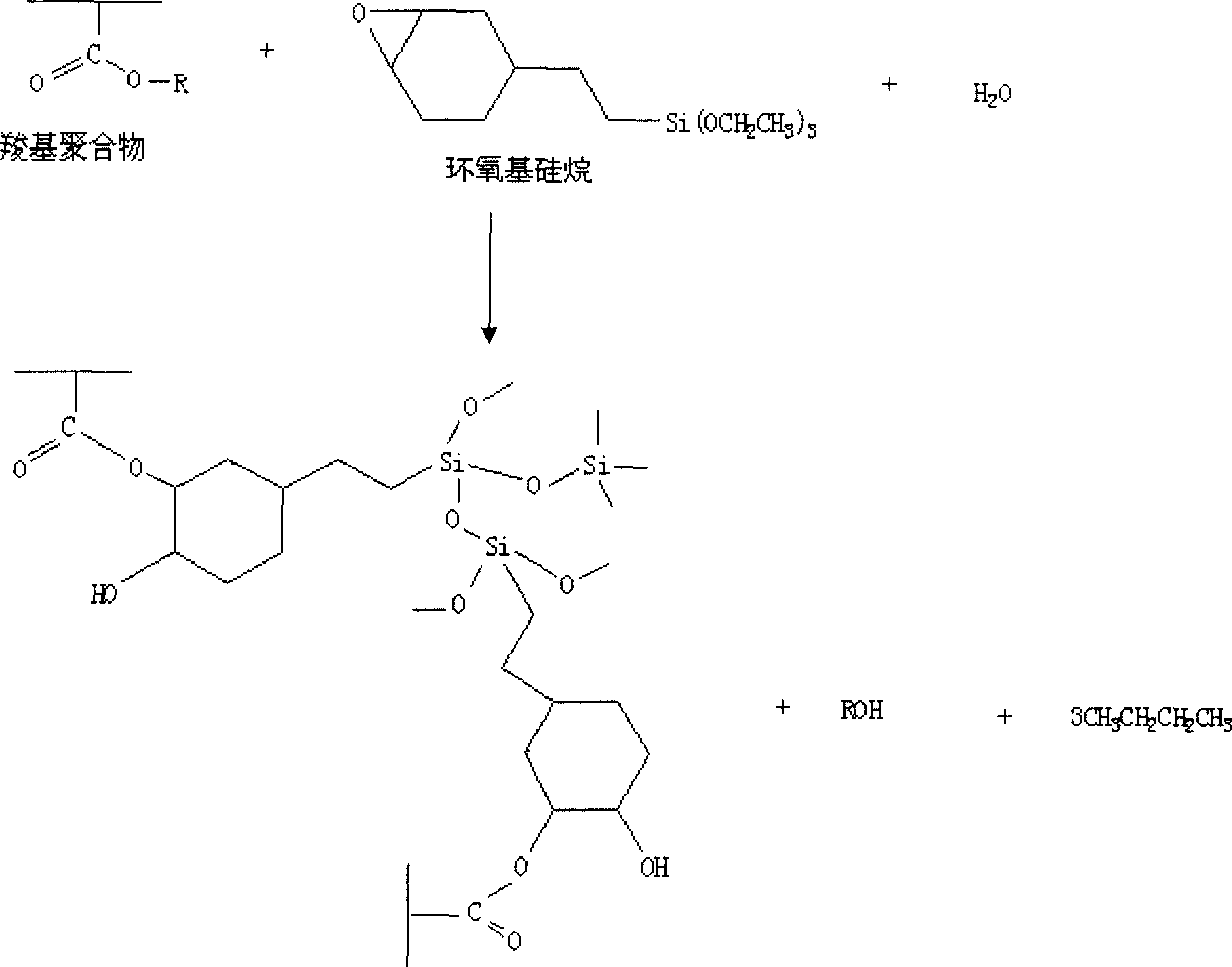

[0032] The preparation method of the negative electrode provided by the present invention includes coating and / or filling the slurry containing the negative active material and the binder and the solvent on the current collector, drying, calendering or not calendering, the binder contains carboxyl polymeric Object, wherein, the adhesive also contains epoxy silane. Wherein, the solvent is water. The amount of the solvent can make the paste have viscosity and fluidity, and can be coated on the current collector. Generally, the amount of the solvent used is 100-150% by weight of the amount of the negative electrode active material. Wherein, the methods and conditions of drying and calendering are well known to those skilled in the art.

[0033] The lithium ion battery provided by the present invention includes a pole core and a non-aqueous electrolyte, the pole core and the non-aqueous electrolyte are sealed in a battery casing, and the pole core includes a positive electrode, ...

Embodiment 1

[0045] This example illustrates the negative electrode provided by the present invention, the lithium ion battery containing the negative electrode and their preparation methods.

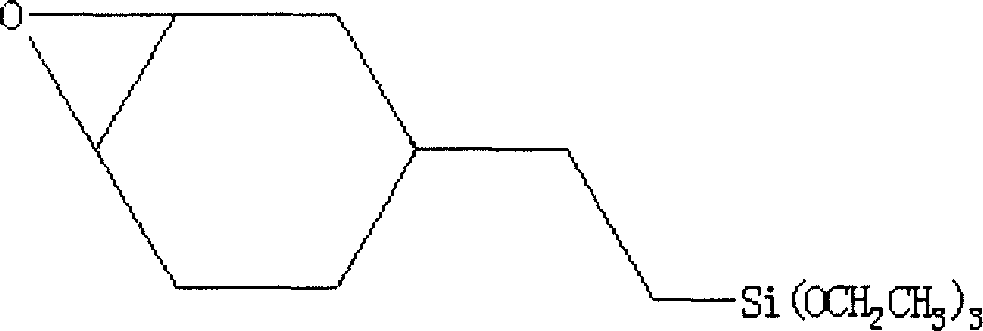

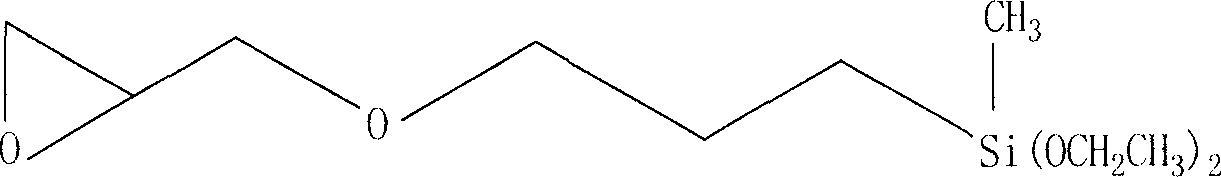

[0046] (1) Preparation of negative electrode

[0047] 100 grams of negative electrode active ingredient natural graphite, 0.4 grams of polyacrylic acid (number average molecular weight is 50000), 0.5 grams of carboxymethyl cellulose, 0.01 grams of β-(3,4-cyclohexyl) ethyltriethoxysilane, 0.01 gram of γ-glycidyl etheroxypropylmethyl diethoxysilane, 4 grams of conductive agent carbon black were added to 100 grams of water, and then stirred to form a uniform negative electrode slurry.

[0048] The slurry was uniformly coated on a copper foil, then dried at 90° C., rolled, and cut to obtain a negative electrode with a size of 500×44 mm, which contained 2.6 grams of natural graphite as an active ingredient.

[0049] (2) Preparation of positive electrode

[0050] 100 g of the positive active ingredient ...

Embodiment 2

[0058] This example illustrates the negative electrode provided by the present invention, the lithium ion battery containing the negative electrode and their preparation methods.

[0059] (1) Preparation of negative electrode

[0060] 100 grams of negative electrode active ingredient natural graphite, 2 grams of polymethacrylic acid (number average molecular weight is 80000), 1.8 grams of sodium hydroxymethylcellulose, 0.01 grams of β-(3,4-cyclohexyl) ethyl triethoxy Silane and 8 grams of conductive agent carbon black were added to 130 grams of water, and then stirred to form a uniform negative electrode slurry.

[0061] The slurry was uniformly coated on a copper foil, then dried at 90° C., rolled, and cut to obtain a negative electrode with a size of 500×44 mm, which contained 2.6 grams of natural graphite as an active ingredient.

[0062] (2) Preparation of positive electrode

[0063] 100 g of the positive active ingredient LiCoO 2 , 2 grams of polyvinylidene fluoride, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com