Attapulgite clay porous ceramsite, and preparation method and purpose thereof

A technology for attapulgite clay and attapulgite powder, which is applied in ceramic products, other household appliances, chemical instruments and methods, etc., can solve the problems of being unsuitable for microbial reproduction, difficult to support microorganisms in film, and small particle porosity, etc. Low price, high strength and low calcination temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In this embodiment, the raw materials of attapulgite clay porous ceramsite are constituted by mass percentage: attapulgite clay 75%, straw 20%, industrial water glass 5%;

[0032] Attapulgite clay porous ceramsite in this embodiment is prepared according to the following steps:

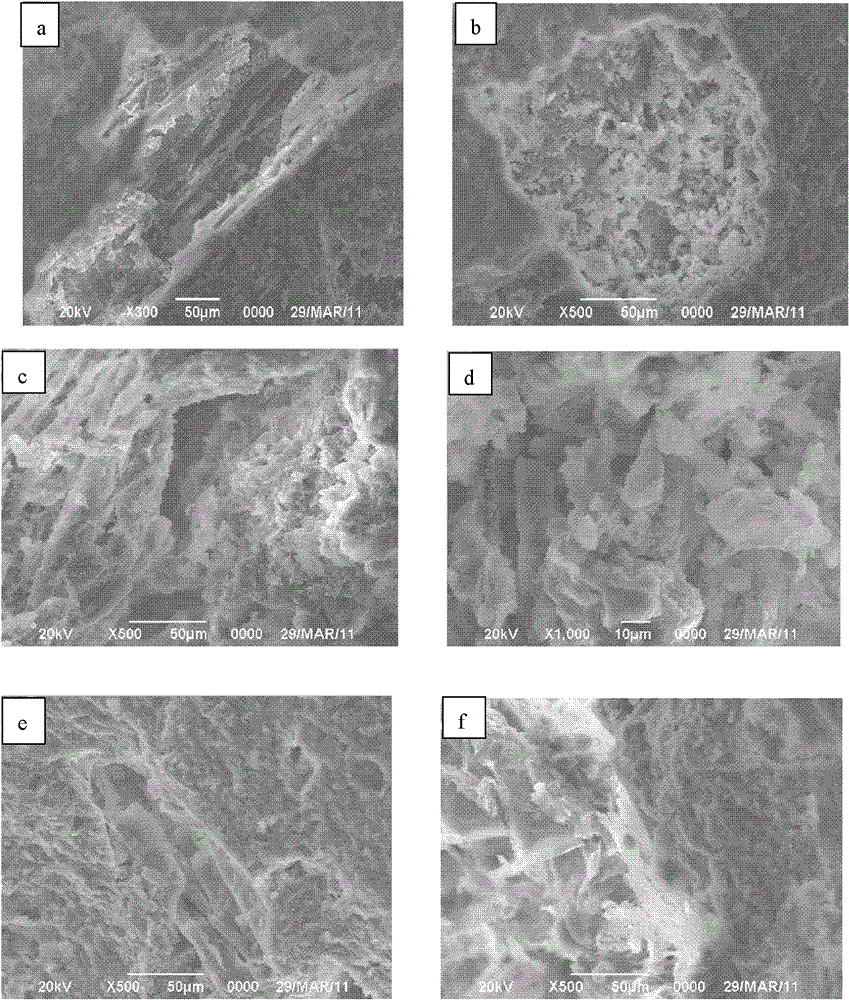

[0033] a, drying and pulverizing the attapulgite clay ore and passing through a 200-mesh sieve to obtain attapulgite powder;

[0034] B, the straw is crushed through a 200-mesh sieve, mixed with industrial water glass and the attapulgite powder obtained in step a to obtain a mixed powder;

[0035] c. Add water to the mixed powder and stir evenly, the amount of water added is 30% of the mass of the mixed powder, granulate and shape, control the particle size at 5-6mm, then dry naturally, and then calcined in the air at 700°C for 2 hours to obtain attapulgite clay porous ceramsite.

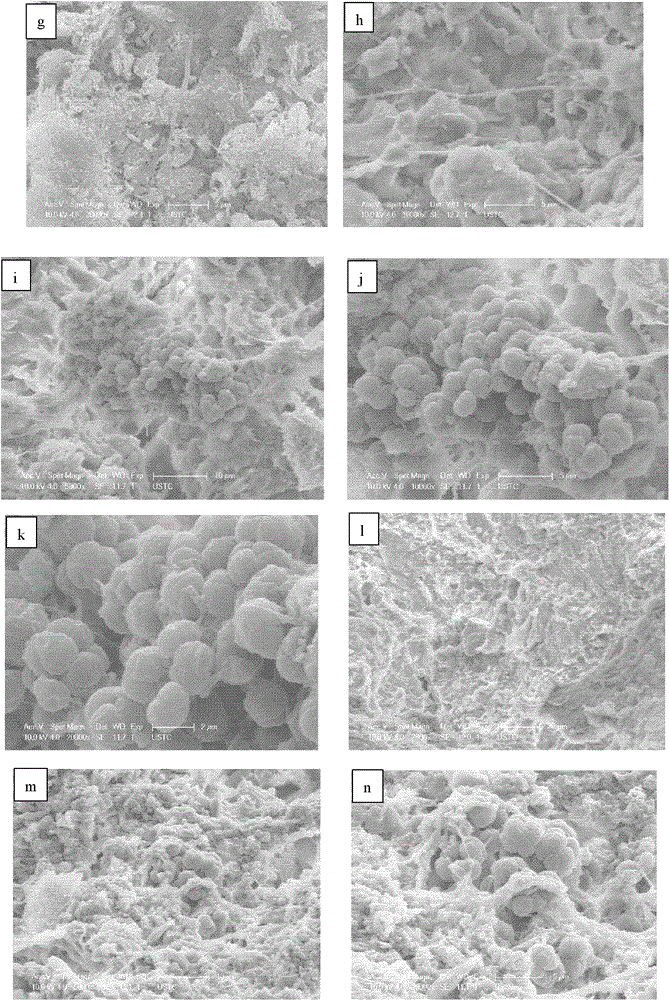

[0036] The attapulgite clay porous ceramsite prepared in this example is used as the carrier of microorganisms i...

Embodiment 2

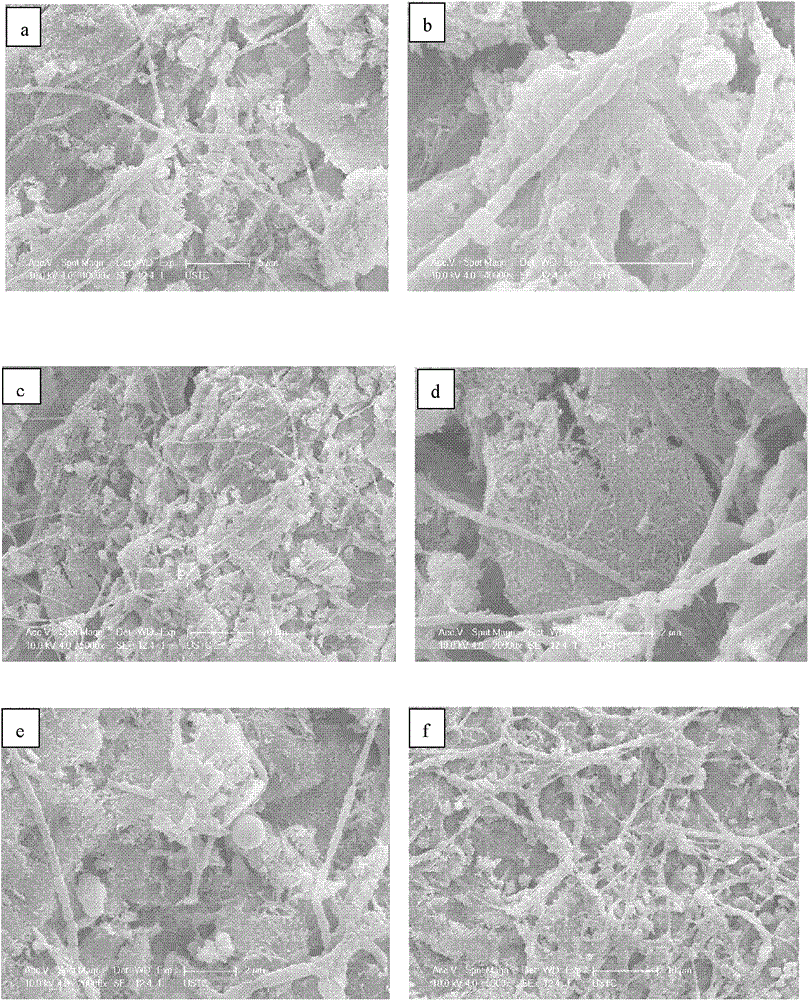

[0041] The raw material of attapulgite clay porous ceramsite in the present embodiment is constituted by mass percentage: attapulgite clay 80%, leaf 10%, industrial water glass 10%;

[0042] Attapulgite clay porous ceramsite in this embodiment is prepared according to the following steps:

[0043] a, drying and pulverizing the attapulgite clay ore and passing through a 200-mesh sieve to obtain attapulgite powder;

[0044] B, the leaves are pulverized through a 200 mesh sieve, mixed with industrial water glass and the attapulgite powder obtained in step a to obtain a mixed powder;

[0045] c. Add water to the mixed powder and stir evenly. The amount of water added is 40% of the mass of the mixed powder. Granulate and shape, control the particle size at 5-7mm, then dry naturally, and then calcined in the air at 500°C for 2 hours to obtain attapulgite clay porous ceramsite.

[0046] The attapulgite clay porous ceramsite prepared in this example is used as a catalyst carrier:

...

Embodiment 3

[0052] The raw material of attapulgite clay porous ceramsite in the present embodiment is constituted by mass percentage: attapulgite clay 85%, sawdust 10%, industrial water glass 5%;

[0053] Attapulgite clay porous ceramsite in this embodiment is prepared according to the following steps:

[0054] a, drying and pulverizing the attapulgite clay ore and passing through a 200-mesh sieve to obtain attapulgite powder;

[0055] B, the sawdust is pulverized through a 200 mesh sieve, mixed with industrial water glass and the attapulgite powder obtained in step a to obtain a mixed powder;

[0056] c. Add water to the mixed powder and stir evenly, the amount of water added is 50% of the mass of the mixed powder, granulate and shape, control the particle size at 5-7mm, then dry naturally, and then calcined in the air at 550°C for 1 hours to obtain attapulgite clay porous ceramsite.

[0057] The attapulgite clay porous ceramsite prepared in this example is used as a catalyst carrier: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com