Toxic flammable gas processing and reusing method for liquid produced from oil well and special device

A technology of flammable gas and special devices, which is applied in the field of toxic and flammable gas treatment and reuse methods and special devices for oil well production fluids, and in the field of toxic and flammable gas treatment and reuse methods and special devices for heavy oil well production fluids. Solve the problems of high labor cost and waste of heat energy, etc., and achieve the effect of preventing environmental pollution, saving energy waste, and huge investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

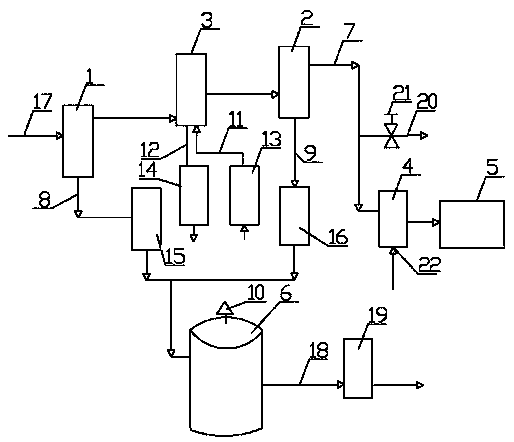

[0018] Example 1: Toxic and flammable gas treatment and reuse method of oil well production fluid, single well fluid (heavy oil thermal production fluid) undergoes the first gas-liquid separation to obtain the first separated gas phase and the first separated liquid phase The gas-liquid mixture is obtained by the first separation of the gas phase through water-cooling heat exchange, the gas-liquid mixture is separated by the second gas-liquid separation to obtain the toxic and flammable gas and the second separation of the liquid phase, and the toxic and flammable gas is sent through the ejector 4 The combustion chamber of the gas-fired boiler 5 burns; the first separation of gas-phase water-cooled heat exchange and cooling water comes from the water of the gas-fired boiler 5, and the return water after the first separation of gas-phase water-cooled heat exchange and cooling returns to the gas-fired boiler 5.

[0019] This method adopts the water-cooling method instead of the e...

Embodiment 2

[0020] Embodiment 2: as attached figure 1 As shown, the special device includes a first gas-liquid separator 1, a second gas-liquid separator 2, a water-cooled heat exchanger 3, an ejector 4, a gas boiler 5 and an oil storage tank 6, and the first gas-liquid separator 1 The gas outlet is connected to the inlet of the hot fluid passage of the water-cooled heat exchanger 3, the outlet of the hot fluid passage of the water-cooled heat exchanger 3 is connected to the inlet of the second gas-liquid separator 2, and the gas outlet of the second gas-liquid separator 2 is connected to the ejector The hydrogen sulfide gas pipeline 7 is connected between the left ports of 4, the gas outlet end of the ejector 4 is connected with the gas inlet end of the gas boiler 5, the liquid outlet end of the first gas-liquid separator 1 is connected with the liquid inlet end of the oil storage tank 6 It is communicated through the first liquid inlet line 8, the liquid outlet end of the second gas-liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com