A low-nitrogen combustion modification method for a circulating fluidized bed boiler

A circulating fluidized bed, low-nitrogen combustion technology, applied in fluidized bed combustion equipment, combustion methods, and fuels burned in a melted state, etc. The effect of reducing NOx emission concentration, improving economy and environmental protection, and reducing consumption of reducing agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

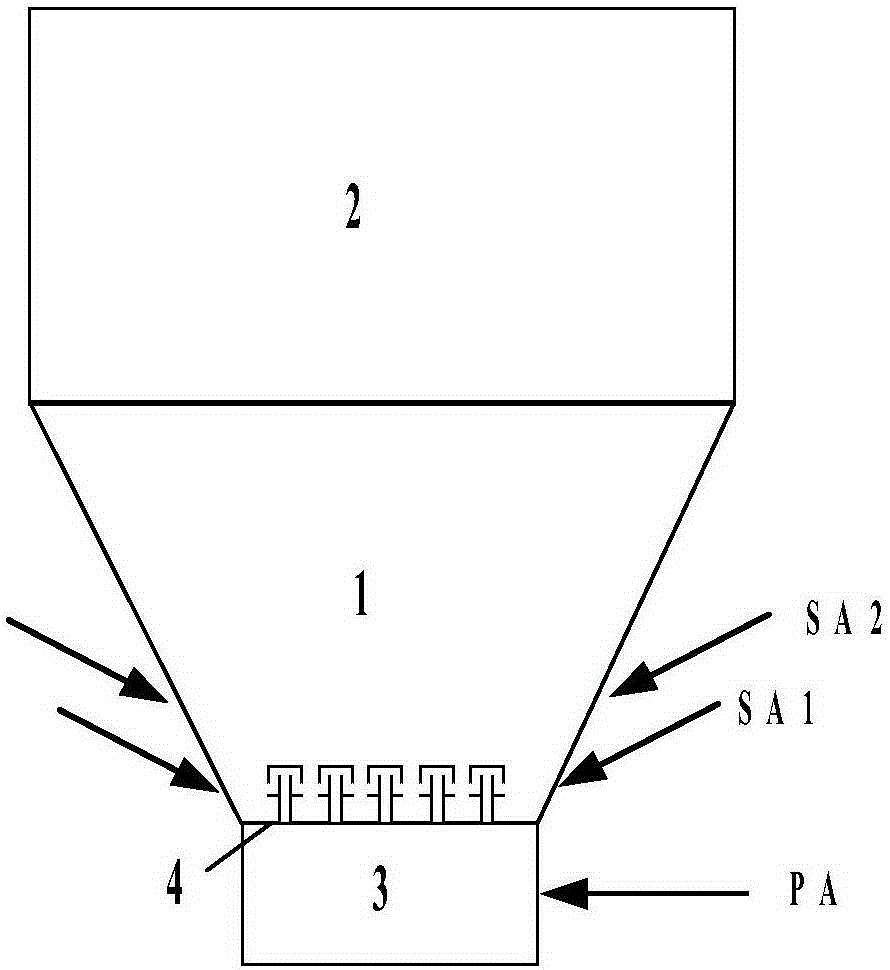

[0063] see Figure 1 to Figure 6 , involving a 480t / h circulating fluidized bed boiler, the boiler burns bituminous coal with a dry ash-free base Vdaf20%, the secondary air of the boiler is divided into two layers SA1 and SA2 in the height direction of the dense phase zone 1 of the furnace, and the primary air The PA volume accounts for 60% of the total wind TA volume, and the NOx emission concentration during operation is 250mg / m 3 .

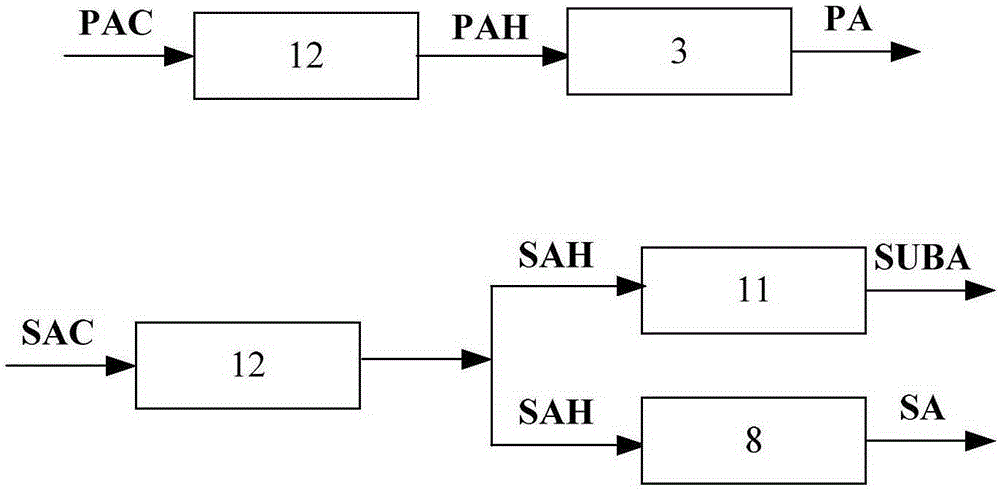

[0064] The primary air-cooled PAC passes through the air preheater 12 to become the primary hot air PAH, and then is sent from the air chamber 3 as the primary air PA to the dense-phase zone 1 of the furnace; the secondary cold air passes through the air preheater 12 to become the secondary hot air SAH, and then is divided into two paths, All the way from the bed burner 11 as the bed burner air SUBA into the dense-phase zone 1 of the furnace, and from the secondary air duct 8 as the secondary air SA into the dense-phase zone 1 of the furnace. ...

Embodiment 2

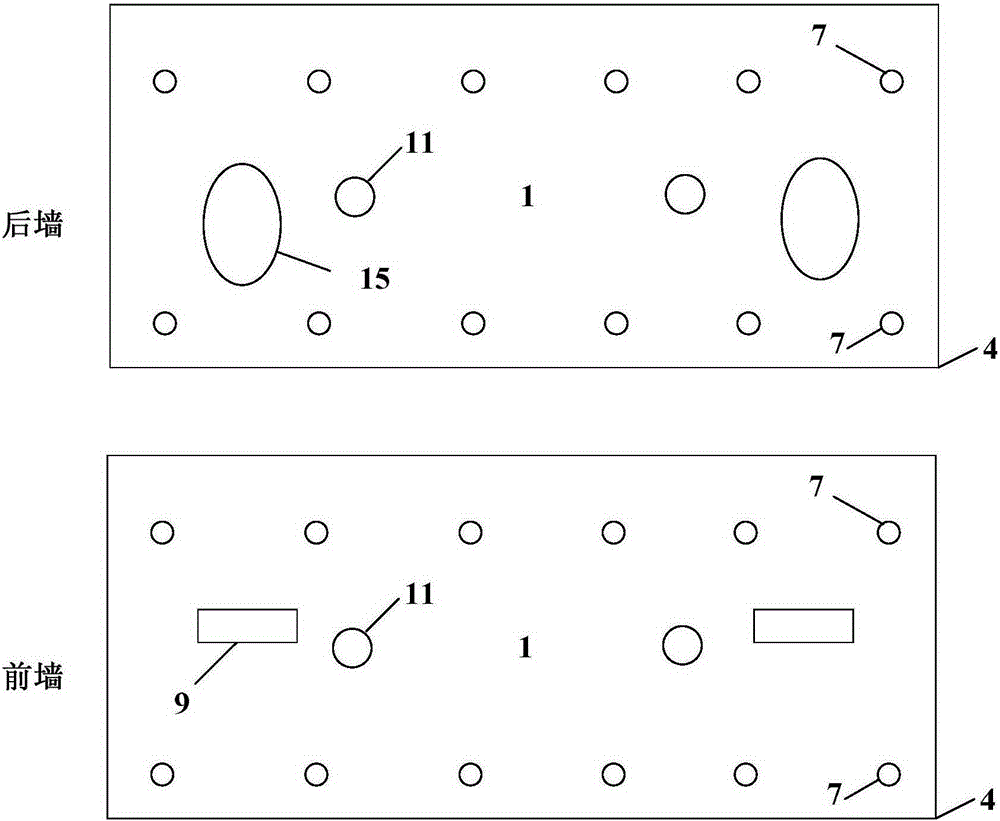

[0075] Involving a 1024t / h circulating fluidized bed boiler, the boiler burns dry ash-free base Vdaf40% lignite, the secondary air of the boiler is divided into two layers SA1 and SA2 in the height direction of the furnace dense phase zone 1, and the primary air PA The air volume accounts for 55% of the total air TA volume. There are two rows of secondary air outlets 7 on the back wall and the front wall of the boiler respectively. The NOx emission concentration during operation is 350mg / m 3 . To reduce NO in boiler flue gas x The emission concentration is high, and the SNCR technology is used for denitrification, and the annual urea consumption is 8,000 tons.

[0076] Carry out low-nitrogen combustion transformation on the boiler, the specific transformation includes:

[0077] The primary air-cooled PAC passes through the air preheater 12 to become a primary hot air PAH, and then is divided into two paths, one path is sent from the bed burner 11 as the bed burner air SUBA t...

Embodiment 3

[0081] Involving a newly built 410t / h circulating fluidized bed boiler, the boiler burns anthracite with a dry ash-free base Vdaf10%, and the boiler secondary air separation and smoke furnace dense-phase zone 1 are divided into four layers SA1, SA2, SA3, SA4 in the height direction The air distribution plate 4 of the primary air system PAS is supplied with a bell-type air cap 5, the distance between the bell-type air caps 5 is 200 mm, and the outermost ring of the air distribution plate 4 is built with a height of 400 mm and a width of 400 mm. Refractory wear-resistant material boss 6.

[0082]Primary air PA accounts for 40% of total air TA, secondary air SA accounts for 50% of total air TA, bed burner air SUBA accounts for 10% of total air TA. The primary air-cooled PAC passes through the air preheater 12 to become primary hot air PAH, and then is divided into two paths, one path is sent from the bed burner 11 as the bed burner air SUBA to the dense-phase zone 1 of the furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com