Loading and unloading system and its loading and unloading method for self unloading binding overhead torch

A loading and unloading system and self-unloading technology, applied in the direction of combustion method, gas fuel burner, combustion type, etc., can solve the problems of potential safety hazards, increase the floor space and protection area of the flare system, and the lack of guide rails and stabilization measures for the flare head. , to achieve the effect of reducing the protection area and saving land area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

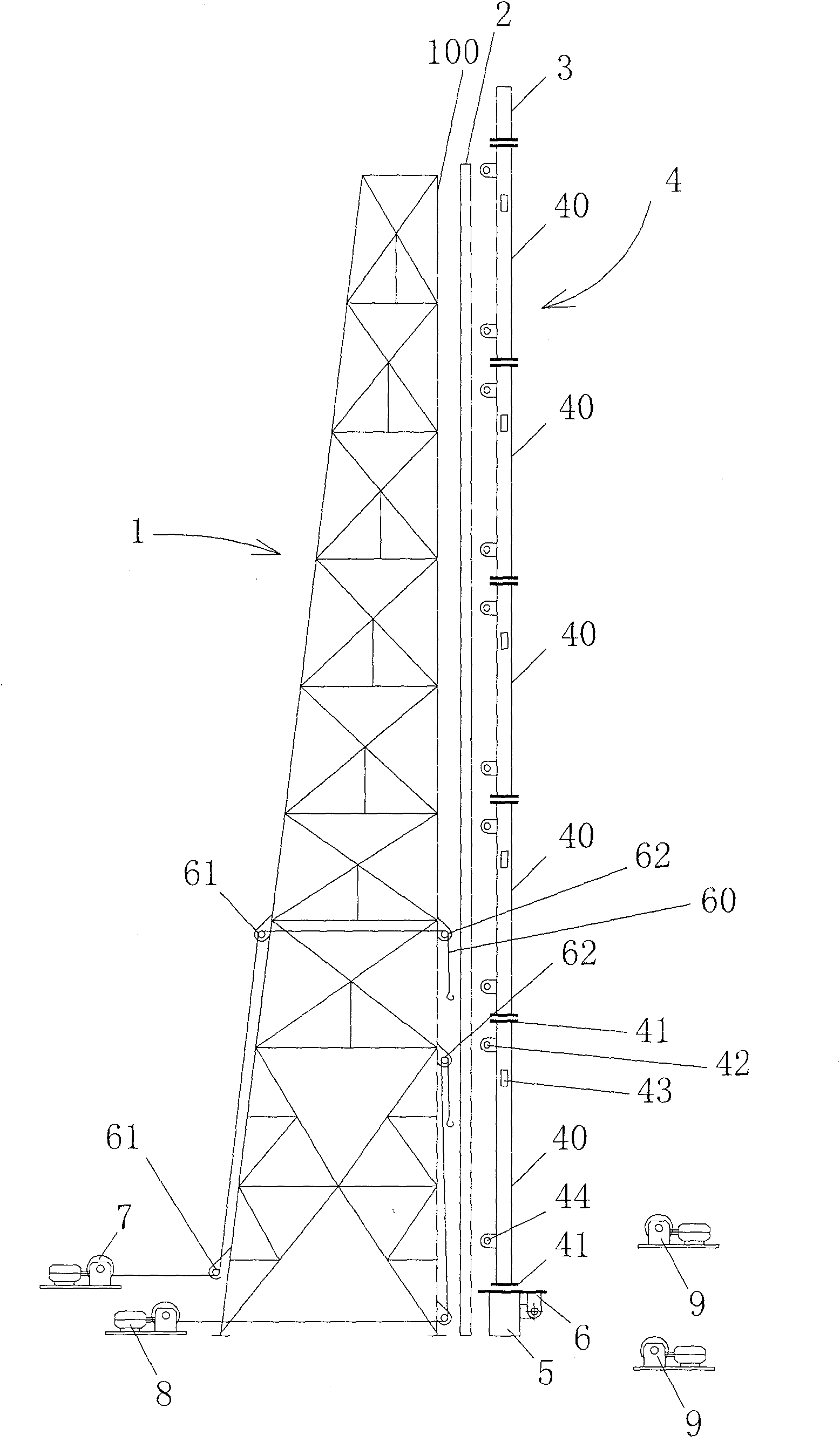

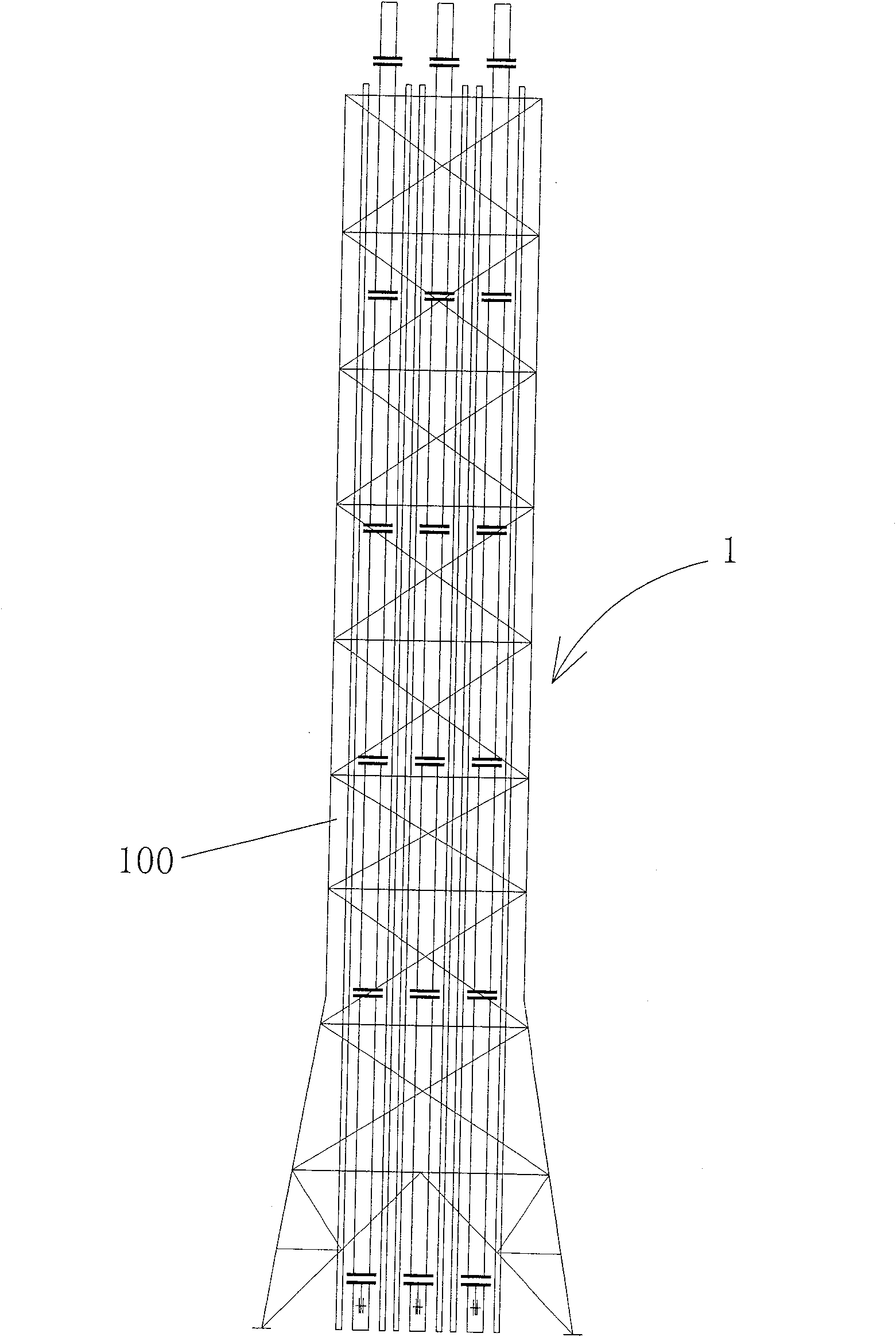

[0037] figure 1 The self-unloading bundled elevated flare and its loading and unloading system of the present invention are shown.

[0038] Such as figure 1 and figure 2 As shown, the flare tower 1 has a vertical side 100 , and the flare barrel 4 is arranged on the side 100 of the tower.

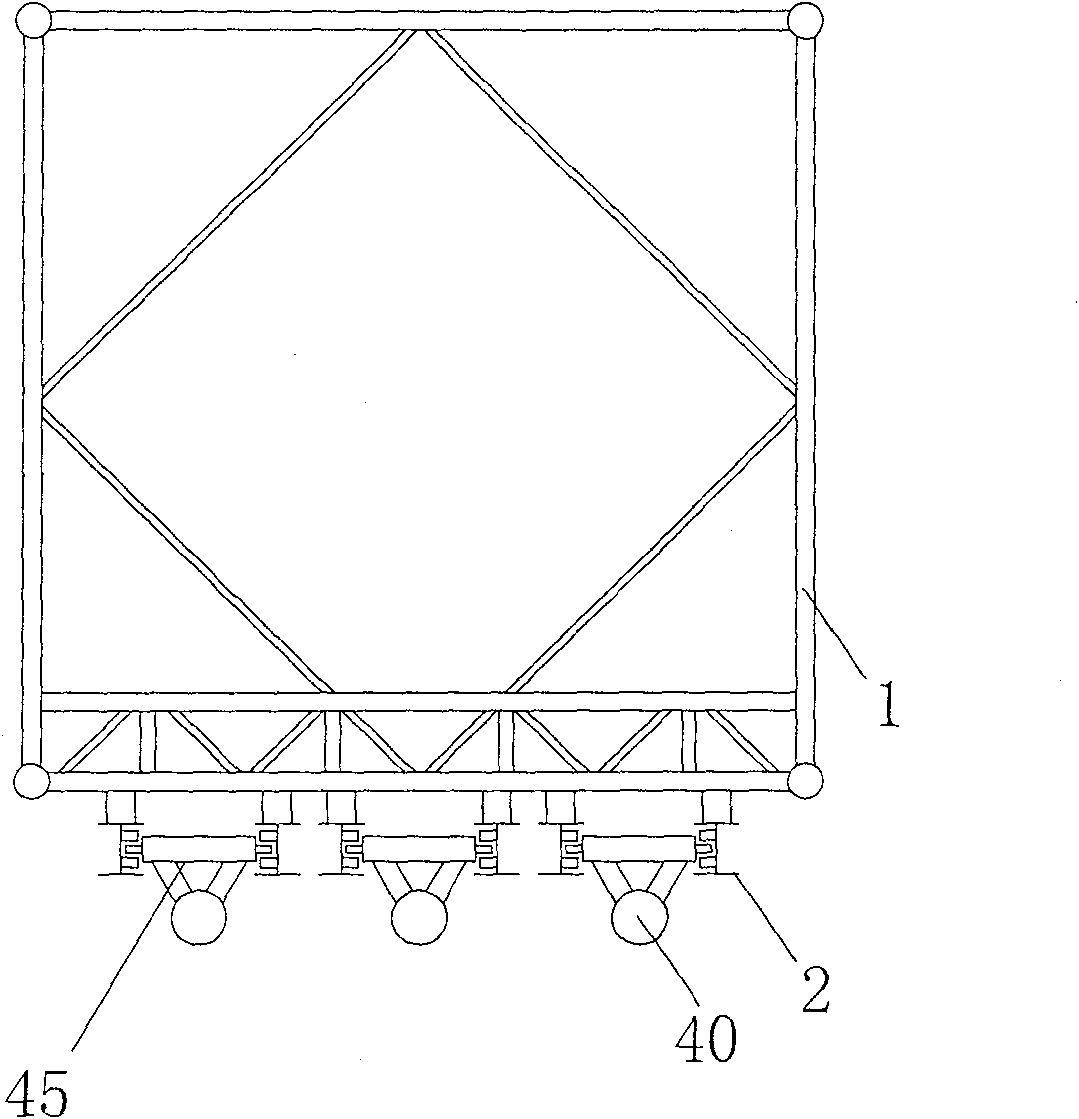

[0039] refer to figure 1 , the torch cylinder 4 is composed of independent multi-section cylinders 40. In this embodiment, the number of sections of the torch cylinder 4 is 5, and the order from bottom to top is the first section, the second section, ... , paragraph 5. Both ends of each cylinder 40 are provided with flanges 41 , and the cylinders 40 of each section are connected by flanges 41 . The flare head 3 is placed on the upper end of the cylinder body 40 of the fifth section and is connected with the cylinder body 40 through the flange 41 provided at the bottom thereof.

[0040]The bottom of the torch cylinder 4 is provided with a basic support 5, and the basic support 5 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com