Slag/calcium carbide cooling and waste heat recycling system

A waste heat recovery system and heat recovery technology, applied in lighting and heating equipment, waste heat treatment, furnace components, etc., can solve the problems of inconvenient heat recovery, complicated cooling process, heat waste, etc., to achieve small size, long equipment life, The effect of high cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

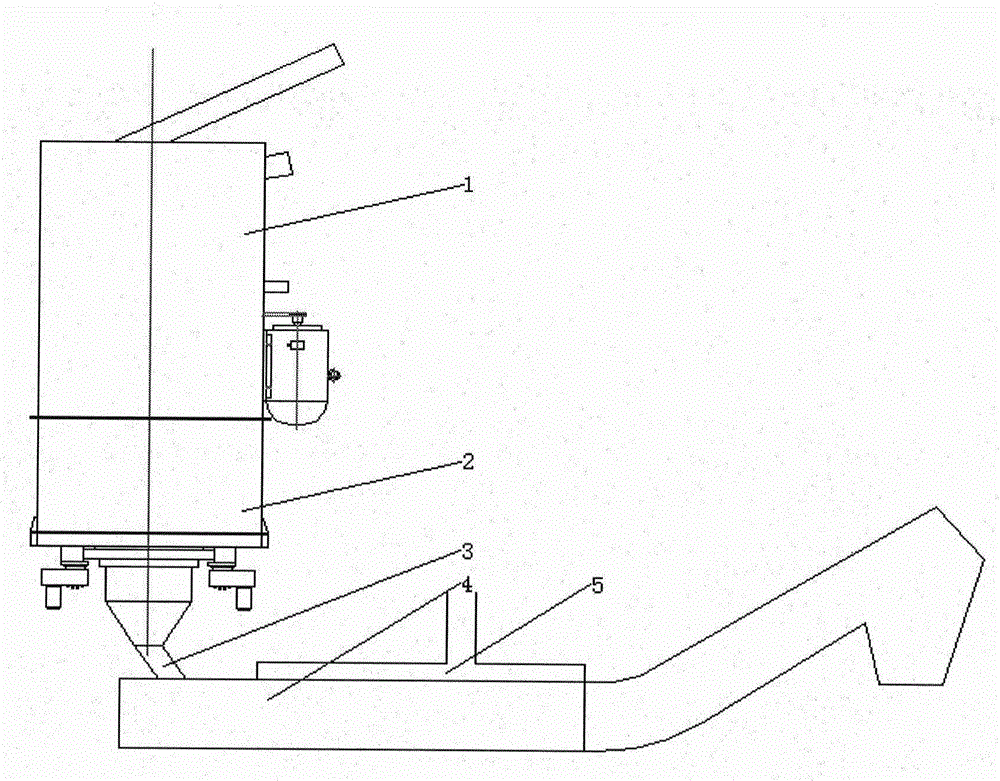

[0036] A steel slag / calcium carbide cooling and waste heat recovery system provided by the present invention includes cooling granulation equipment 1, the lower part of the cooling granulation equipment 1 is connected to the unloading equipment 2, and the lower part of the unloading equipment 2 is installed with a drop pipe 3, and the drop pipe 3 The secondary heat recovery and delivery equipment 4 is obliquely inserted, and the heat recovery pipeline 5 is installed on the upper part of the secondary heat recovery and delivery equipment 4 .

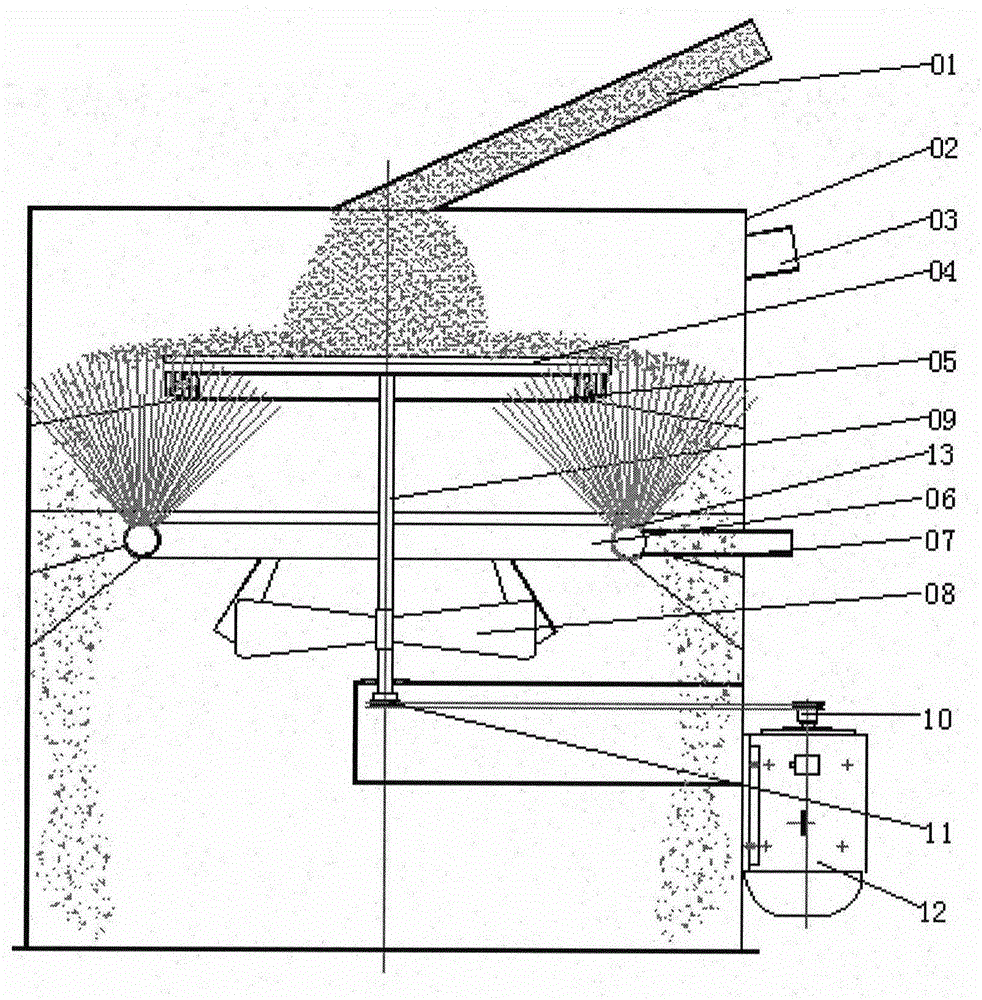

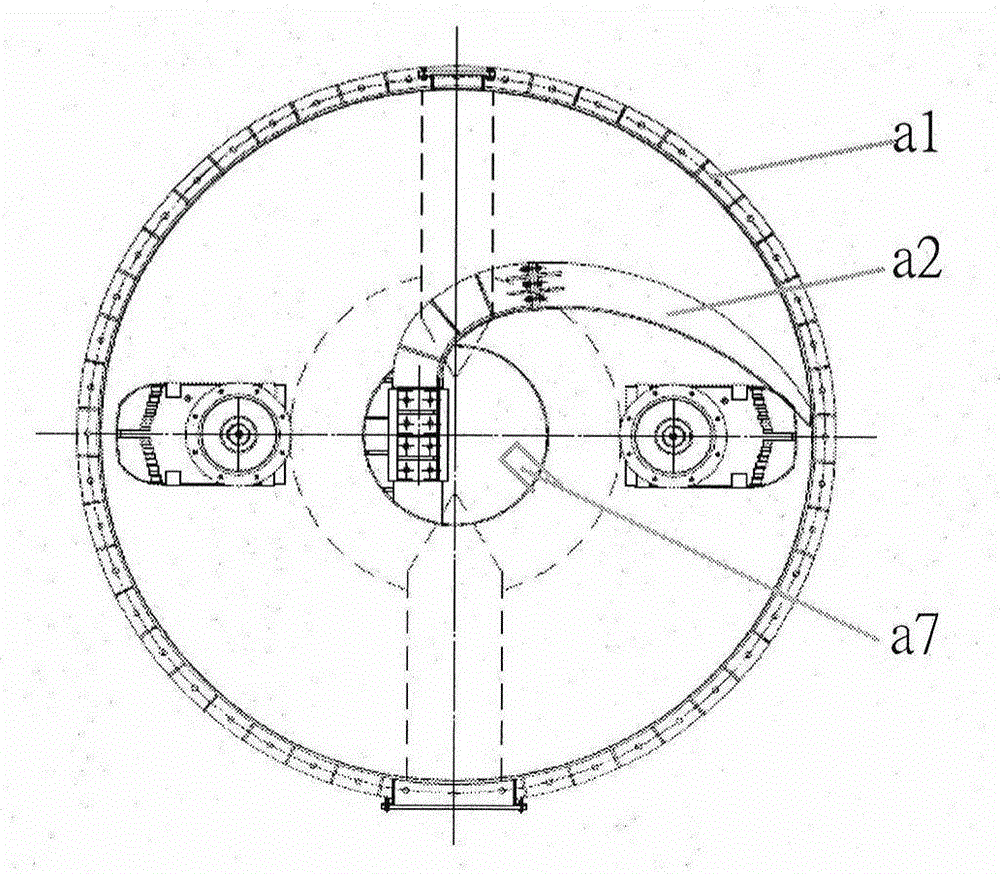

[0037] The cooling and granulating equipment 1 includes a feed pipe 01, which is obliquely inserted into a cooling kettle 02 and welded as a whole. The inner axis of the cooling kettle 02 is equipped with a turntable 04. The turntable 04 is connected to the turntable seat 05 through a rotating support. The turntable seat 05 is fixed on the inner wall of the cooling kettle 02 by welding through a bracket; the drive shaft 09 is installed und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com