Fire coal dust suppressant and preparation method thereof

A dust suppressant, coal-burning technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of poor anti-evaporation ability, short effective dust suppression time, large water consumption, etc. Good dust effect, easy to spray effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

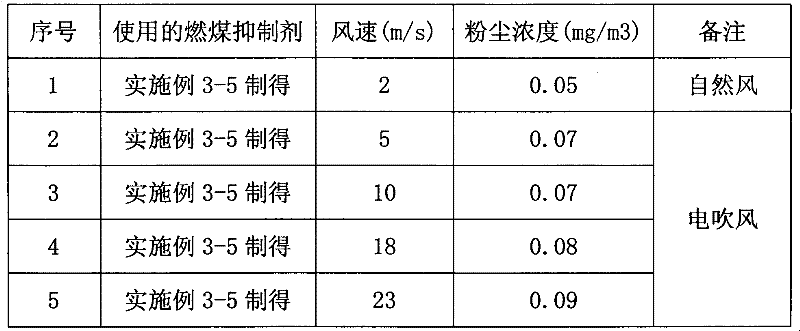

Examples

Embodiment 1

[0041] Prepare coal-fired dust suppressant according to the following steps:

[0042] The first step: in a dry nitrogen environment, add 100 parts of polyether diols with a molecular weight of 1000, 100 parts of polyether diols with a molecular weight of 2000, 80 parts of isophorone diisocyanate, 20 parts of epoxy resin E-51, then add 5 parts of dibutyltin dilaurate T-12, mix well and then heat up to 80°C for 1.5 hours;

[0043] The second step: add 10 parts of 2,2-dimethylolpropionic acid into the three-necked flask, and react at 80°C for 0.5 hours;

[0044] The third step: add 3 parts of diethylene glycol and acetone whose weight is 1 times of the reactant obtained in the second step to the three-necked flask, and react at 50°C for 1.5 hours. polymer, the prepolymer is poured out of the reactor;

[0045] Step 4: Add 3 parts of triethylamine and 200 parts of deionized water to the prepolymer, and stir with a mixer at a rate of 1800 rpm for 10 hours at room temperature to ob...

Embodiment 2

[0048] Prepare coal-fired dust suppressant according to the following steps:

[0049] The first step: under the environment of dry nitrogen, add 200 parts of polyether diols with a molecular weight of 1000, 200 parts of polyether diols with a molecular weight of 2000, 100 parts of isophorone diisocyanate, 35 parts of epoxy resin E-51, then add 15 parts of dibutyltin dilaurate T-12, mix well and then heat up to 90°C for 2.5 hours;

[0050] The second step: add 20 parts of 2,2-dimethylolpropionic acid to the three-necked flask, and react at 90°C for 1.5 hours;

[0051] Step 3: Add 10 parts of diethylene glycol and acetone twice the weight of the reactant obtained in the second step to the three-necked flask, and react at 70°C for 2.5 hours. After the reaction is completed, let it stand until the temperature is 45°C. polymer, the prepolymer is poured out of the reactor;

[0052] Step 4: Add 10 parts of triethylamine and 300 parts of deionized water to the prepolymer, and stir w...

Embodiment 3

[0055]The first step: in a dry nitrogen environment, add 150 parts of polyether diols with a molecular weight of 1000, 150 parts of polyether diols with a molecular weight of 2000, 90 parts of isophorone diisocyanate, 28 parts of epoxy resin E-51, then add 10 parts of dibutyltin dilaurate T-12, mix evenly and heat up to 85°C for 2 hours;

[0056] The second step: add 15 parts of 2,2-dimethylolpropionic acid to the three-necked flask, and react at 85°C for 1 hour;

[0057] The third step: add 5 parts of diethylene glycol and acetone whose weight is 1.2 times the weight of the reactant obtained in the second step to the three-necked flask, and react at 60°C for 2 hours. After the reaction is completed, let it stand until the temperature is 40°C. polymer, the prepolymer is poured out of the reactor;

[0058] Step 4: Add 5 parts of triethylamine and 280 parts of deionized water to the prepolymer, and stir with a mixer at a rate of 1500 rpm for 15 hours at room temperature to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com