One-way detonation device of penetrating rotary detonation engine

A detonation engine and detonation device technology, applied in the direction of combustion engine, machine/engine, internal combustion piston engine, etc., to achieve the effect of ensuring reliability, reasonable design and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

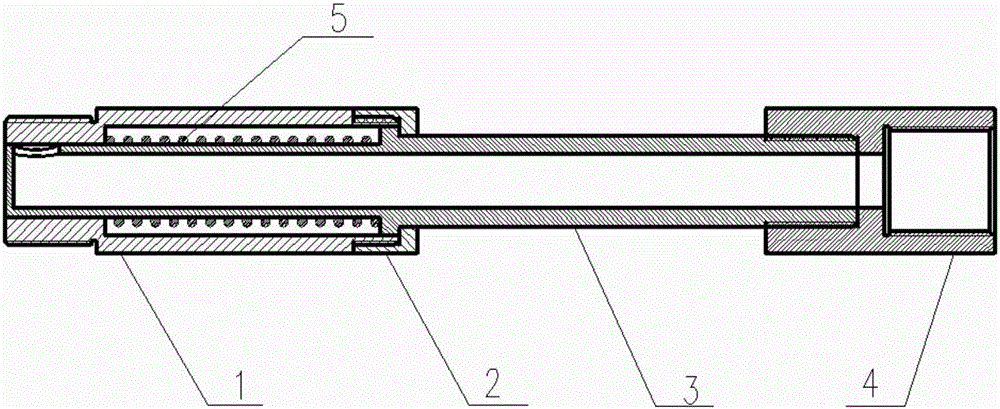

[0036] A one-way detonation device for a penetrating rotary detonation engine,

[0037] comprising a mount 1 configured for fixing to an outer wall of a rotary detonation engine,

[0038] a pre-detonation tube 3 passing through the mounting seat 1 and slidingly fitted with the mounting seat,

[0039] a detonation tube adapter device 4 configured to connect the pre-detonation tube 3 and the ignition tube,

[0040] The end cover 2 of the mounting seat that is arranged on the end of the mounting seat 1 to limit the position of the pre-detonation tube 3 in the sliding direction,

[0041] On the pre-detonation tube 3, the elastic element 5 exerts elastic force on the pre-detonation tube 3 in its sliding direction;

[0042] Wherein, the annular combustion chamber of the rotary detonation engine has an opening for the pre-detonation tube 3 to extend into, and the side wall of the pre-detonation tube 3 has an opening communicating with the annular combustion chamber.

Embodiment 2

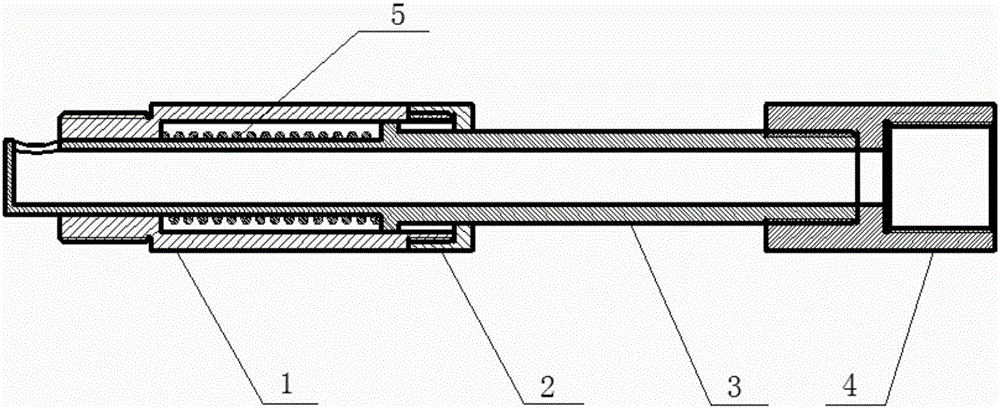

[0044] A one-way detonation device for a penetrating rotary detonation engine,

[0045] comprising a mount 1 configured for fixing to an outer wall of a rotary detonation engine,

[0046] a pre-detonation tube 3 passing through the mounting seat 1 and slidingly fitted with the mounting seat,

[0047] a detonation tube adapter device 4 configured to connect the pre-detonation tube 3 and the ignition tube,

[0048] The end cover 2 of the mounting seat that is arranged on the end of the mounting seat 1 to limit the position of the pre-detonation tube 3 in the sliding direction,

[0049] On the pre-detonation tube 3, the elastic element 5 exerts elastic force on the pre-detonation tube 3 in its sliding direction;

[0050] Wherein, the annular combustion chamber of the rotary detonation engine has an opening for the pre-detonation tube 3 to extend into, and the side wall of the pre-detonation tube 3 has an opening communicating with the annular combustion chamber.

[0051] The det...

Embodiment 3

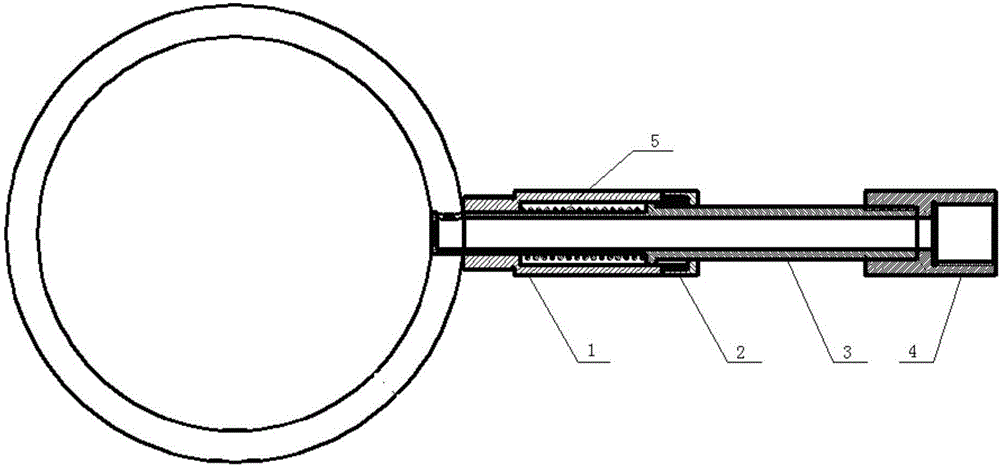

[0053] A one-way detonation device for a penetrating rotary detonation engine,

[0054] comprising a mount 1 configured for fixing to an outer wall of a rotary detonation engine,

[0055] a pre-detonation tube 3 passing through the mounting seat 1 and slidingly fitted with the mounting seat,

[0056] a detonation tube adapter device 4 configured to connect the pre-detonation tube 3 and the ignition tube,

[0057] The end cover 2 of the mounting seat that is arranged on the end of the mounting seat 1 to limit the position of the pre-detonation tube 3 in the sliding direction,

[0058] On the pre-detonation tube 3, the elastic element 5 exerts elastic force on the pre-detonation tube 3 in its sliding direction;

[0059] Wherein, the annular combustion chamber of the rotary detonation engine has an opening for the pre-detonation tube 3 to extend into, and the side wall of the pre-detonation tube 3 has an opening communicating with the annular combustion chamber.

[0060] The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com