Quick coupling

A fast, on-the-spot technology, applied in mechanical equipment, couplings, etc., can solve the problems of harmful substances affecting water quality, high use cost, high cost, and achieve the effect of convenient and quick installation and disassembly, lower production cost, and simple manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

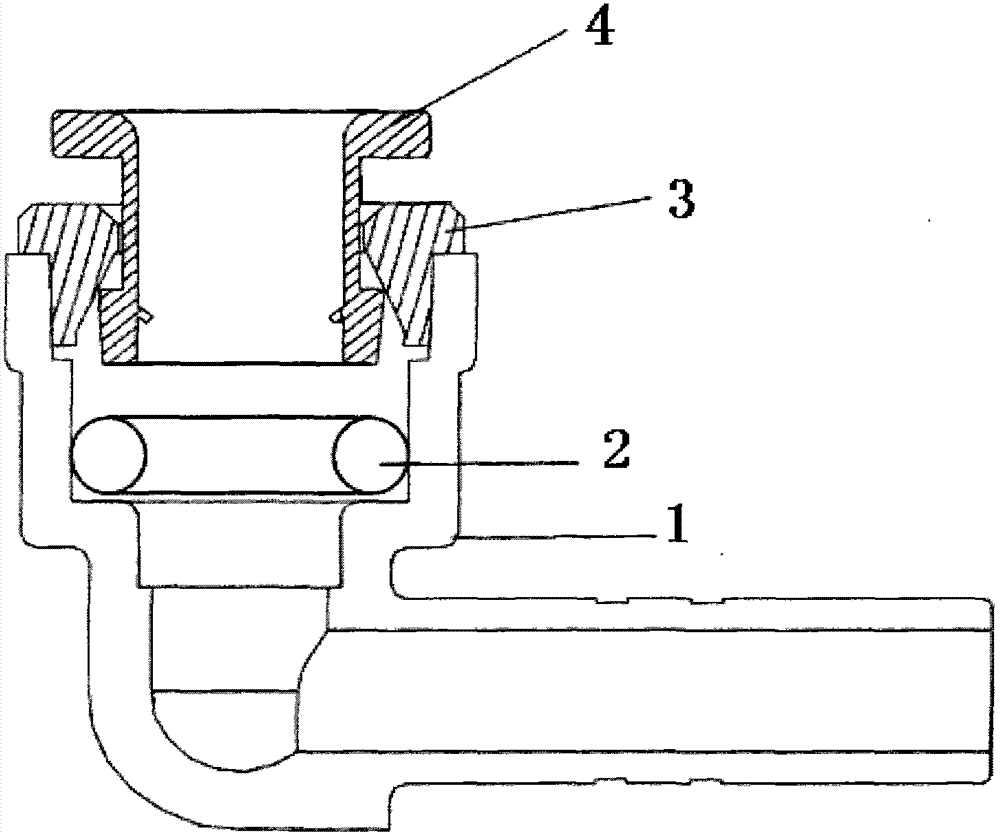

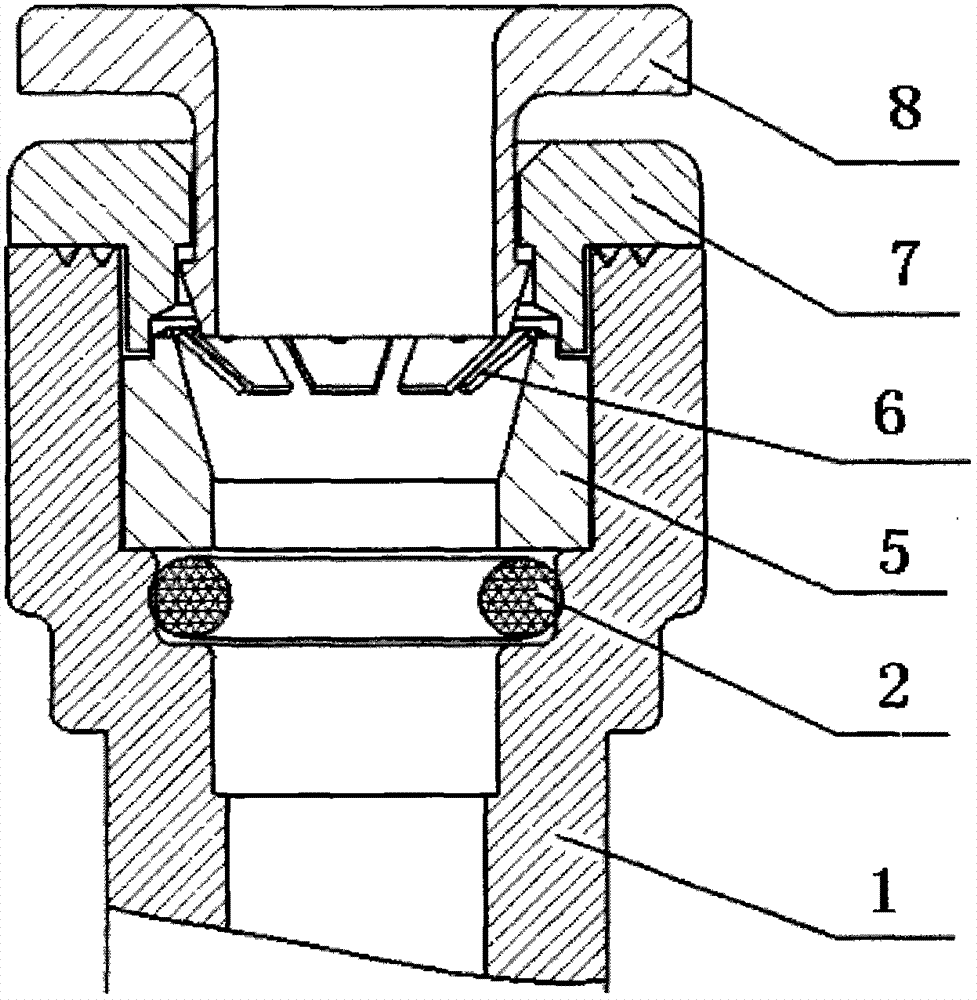

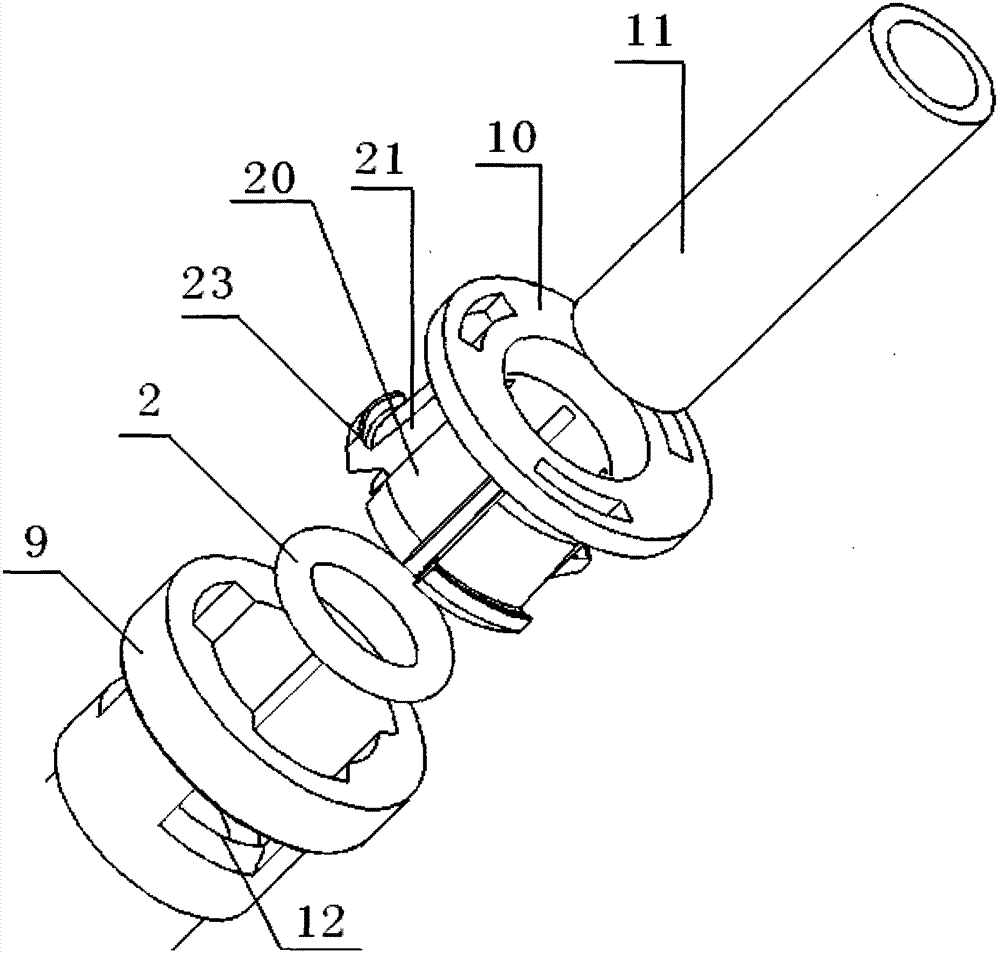

[0035]Referring to the accompanying drawings, a quick connector includes a connecting body 9, a sealing ring 2, a multifunctional movable sleeve 10, and three major components. The elastic arm barb pawl 23 that the multifunctional movable cover is provided with is buckled in the square side through hole 12 that the connecting body is provided with, the quantity of the square side through hole 12 is equal to the quantity of the elastic arm barb claw 23, and the multifunctional movable cover 10 and the connecting body 9 move toward each other when the elastic arm barb claw 23 is hooked on the hook wall 14 of the connecting body, and there is zero gap between the elastic arm sub-foot 24 and the edge of the square side through hole slope 13, and the elastic arm inner slope 22 and square side through hole slope 13 intersect.

[0036] The multifunctional movable cover 10 includes a plurality of fixed limit feet 20, a plurality of elastic arms 21, an inner slope 22 of a plurality of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com