Apparatus and method for mounting belt of belt conveyor

A technology for belt conveyors and installation devices, which is applied in the direction of conveyors, belt fasteners, transportation and packaging, etc., can solve the problems that the replacement and installation of old belts cannot be realized, and achieve convenient transportation and repeated use, flexible operation, The effect of reducing replacement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

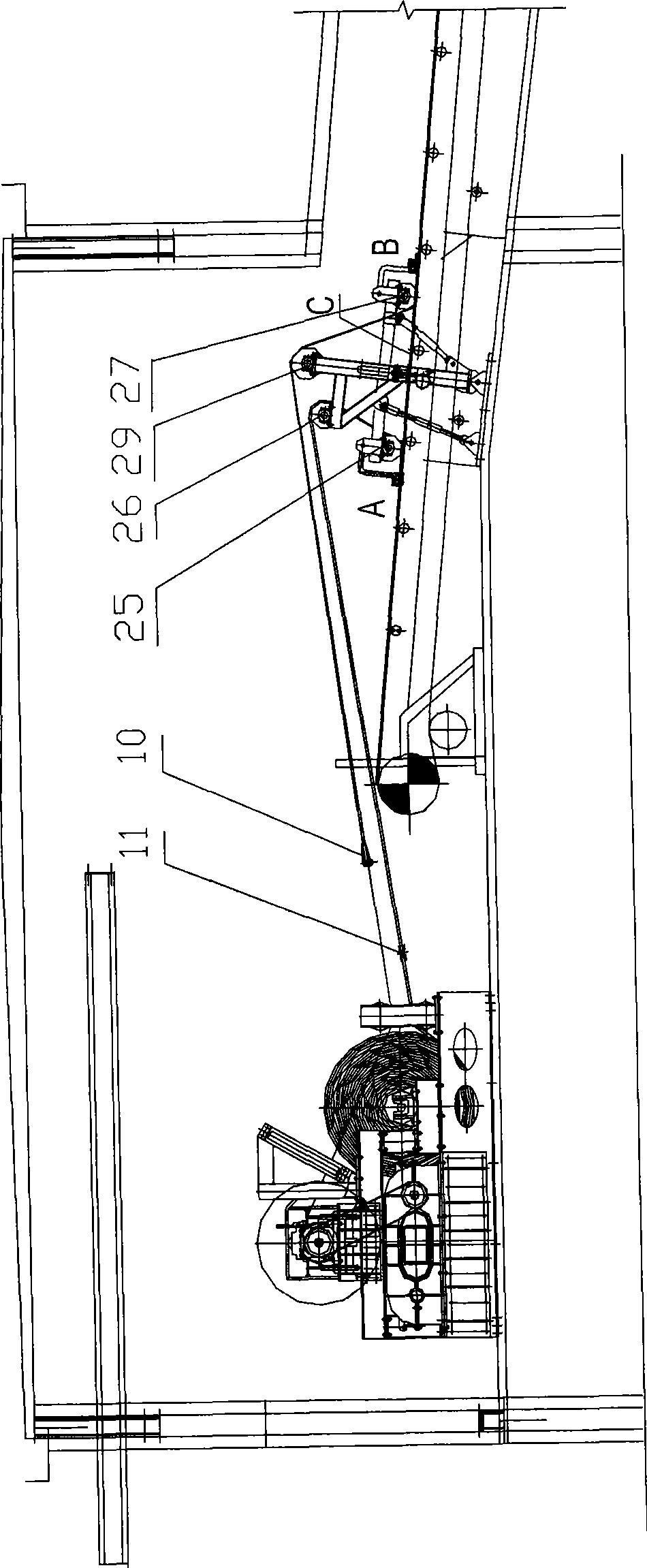

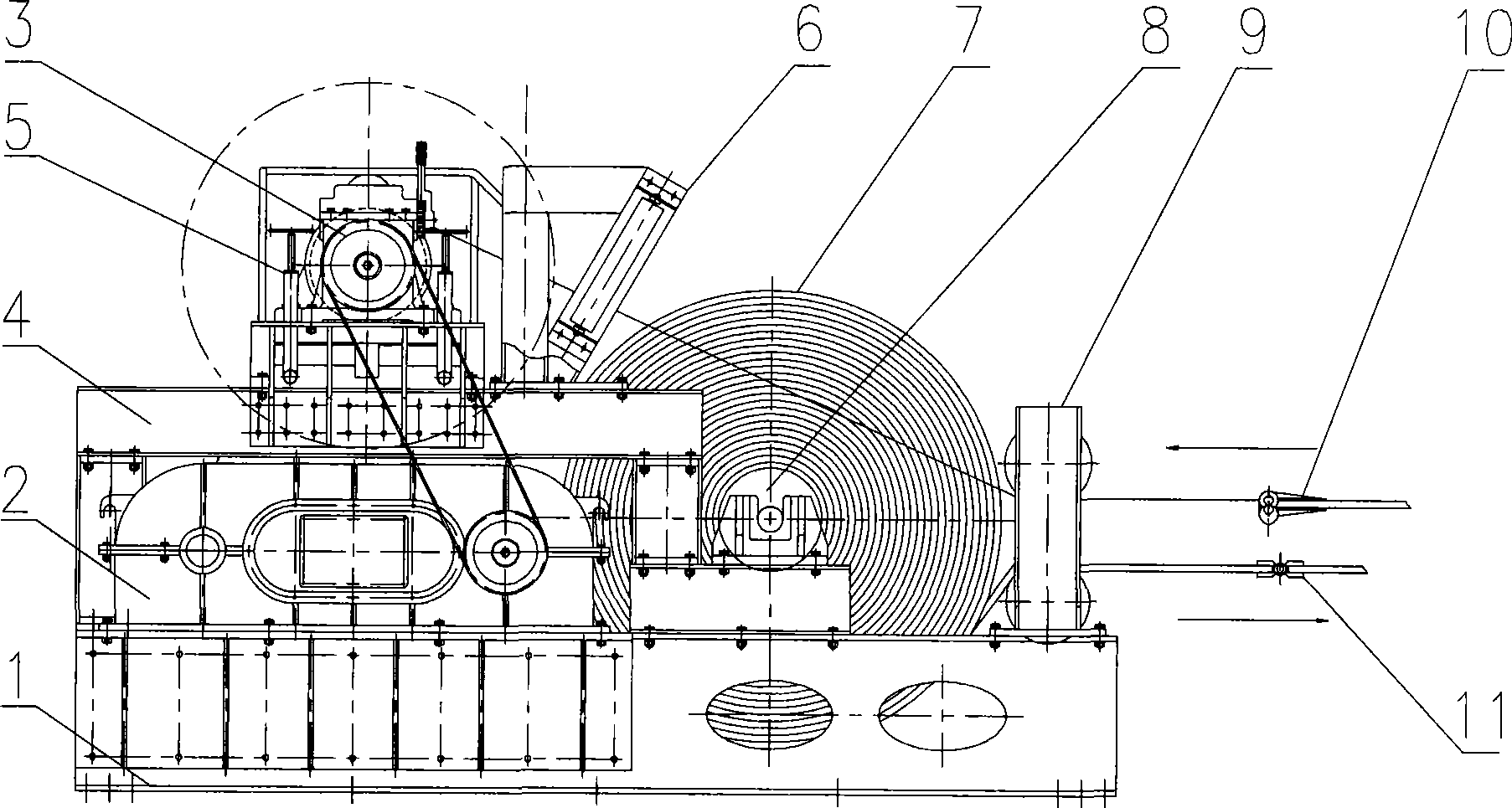

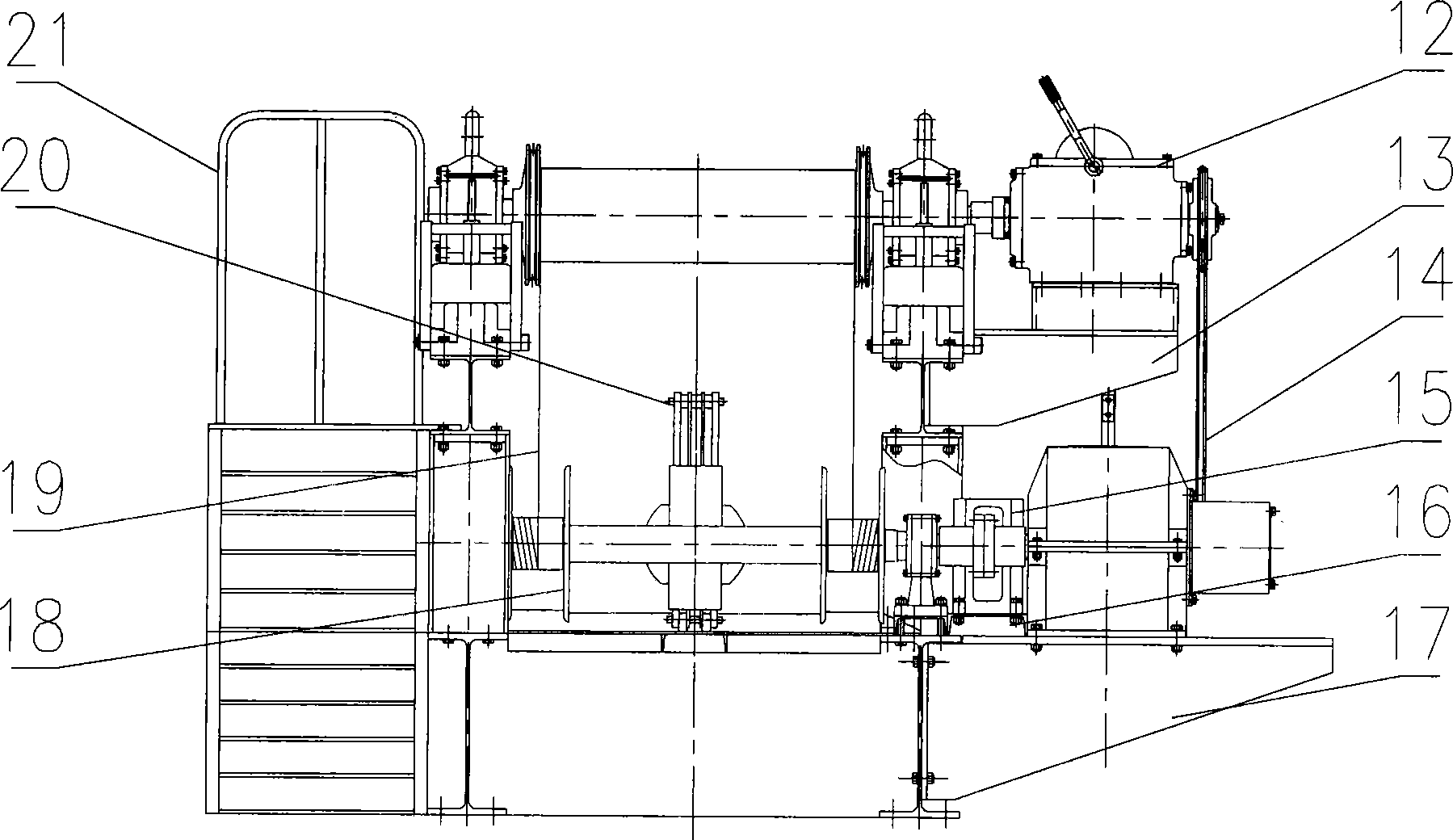

[0031] The structure and installation method of the belt conveyor belt installation device of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0032] See figure 1 , figure 2 , image 3 , Figure 4 , a belt conveyor belt installation device, the device includes two parts of the main machine and the middle switch guide device, the main machine consists of a main machine frame 1, a double output hand-electric switching device 2, an old tape reel 3, and an old tape roll Barrel bracket 4, support locking device 5, anti-deviation bracket 6, new tape reel 7, new tape reel support seat 8, guide roller group 9, wire rope pull tape clip 10, new and old tape connection clip 11, transmission mechanism 12, transmission Mechanism support seat 13, transmission chain 14, planetary cycloid reducer 15, planetary cycloid reducer support 16, switching device support 17, wire rope reel group 18, steel wire rope 19, brake 20, operating pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com