Girders assembling external member as well as girders and girders support system

A support system and truss technology, applied in the field of load-bearing trusses, can solve problems such as unsatisfactory economic benefits, difficult to turn over and use, and inability to keep them intact, and achieve the effects of convenient and fast disassembly, fast construction speed, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The detailed technical content of the patent application of the present invention will be described in detail below in conjunction with each accompanying drawing.

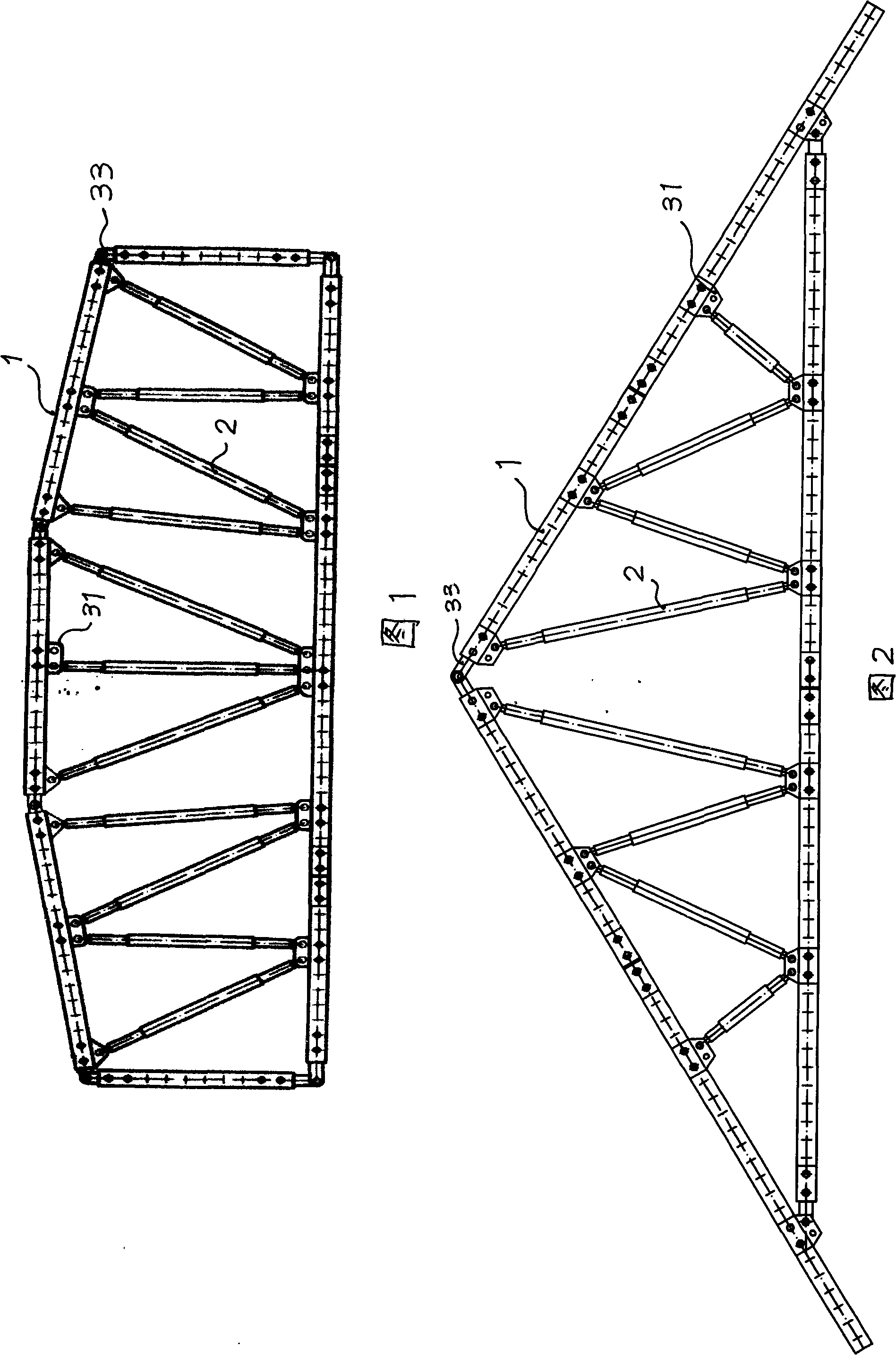

[0028] The truss is assembled by truss assembly kit, and its truss is usually constructed by upper and lower chords, side chords and webs between the upper and lower chords, as shown in Figure 1; it can also be as shown in Figure 2 The triangular truss is actually a deformed structure of the truss in Figure 1, that is, the gusset plate shaft frame 33 is set in the middle of the upper chord to form a corner hinge, and it is connected with the lower chord, and the web 2 is arranged between the upper and lower chords.

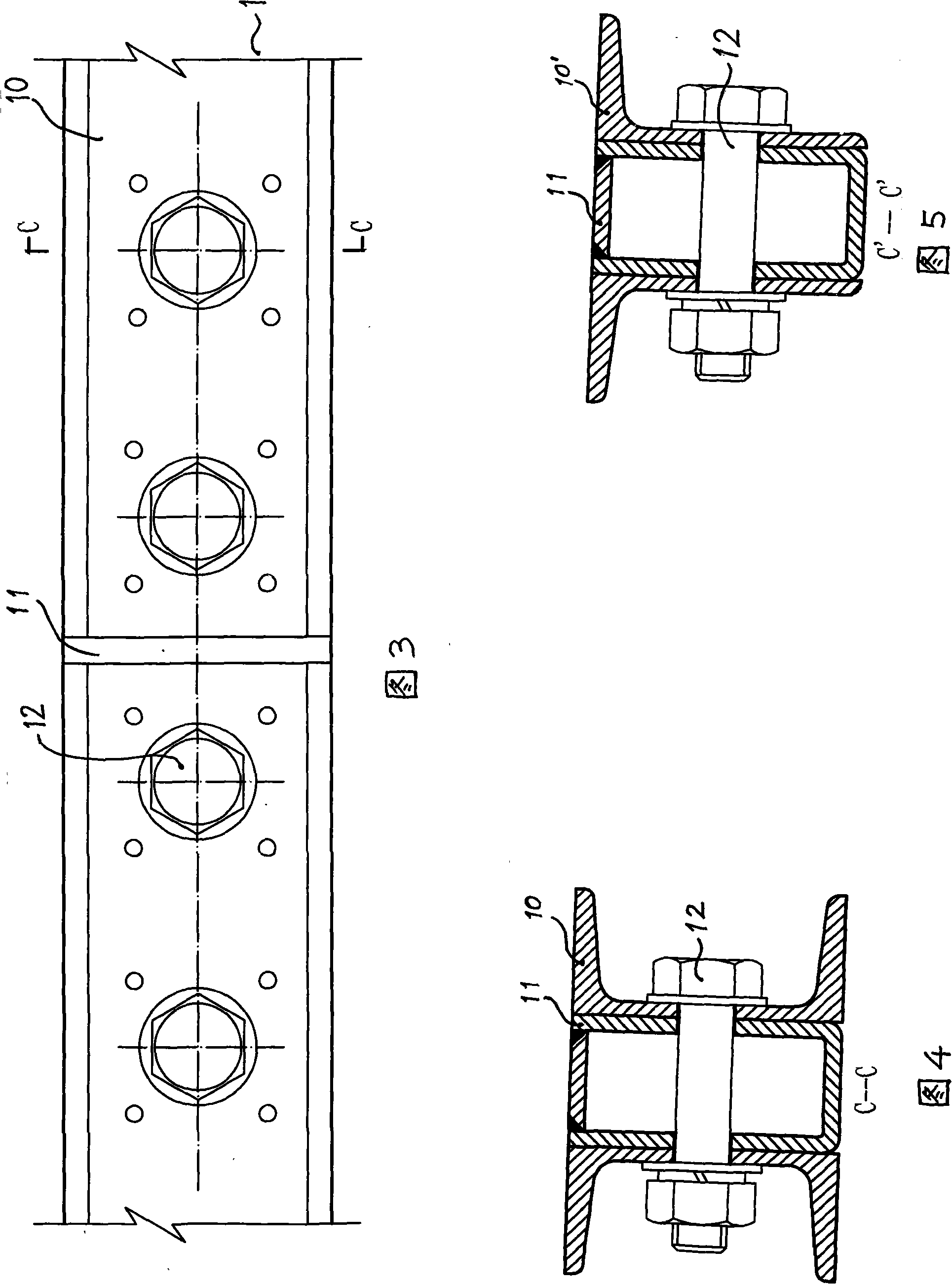

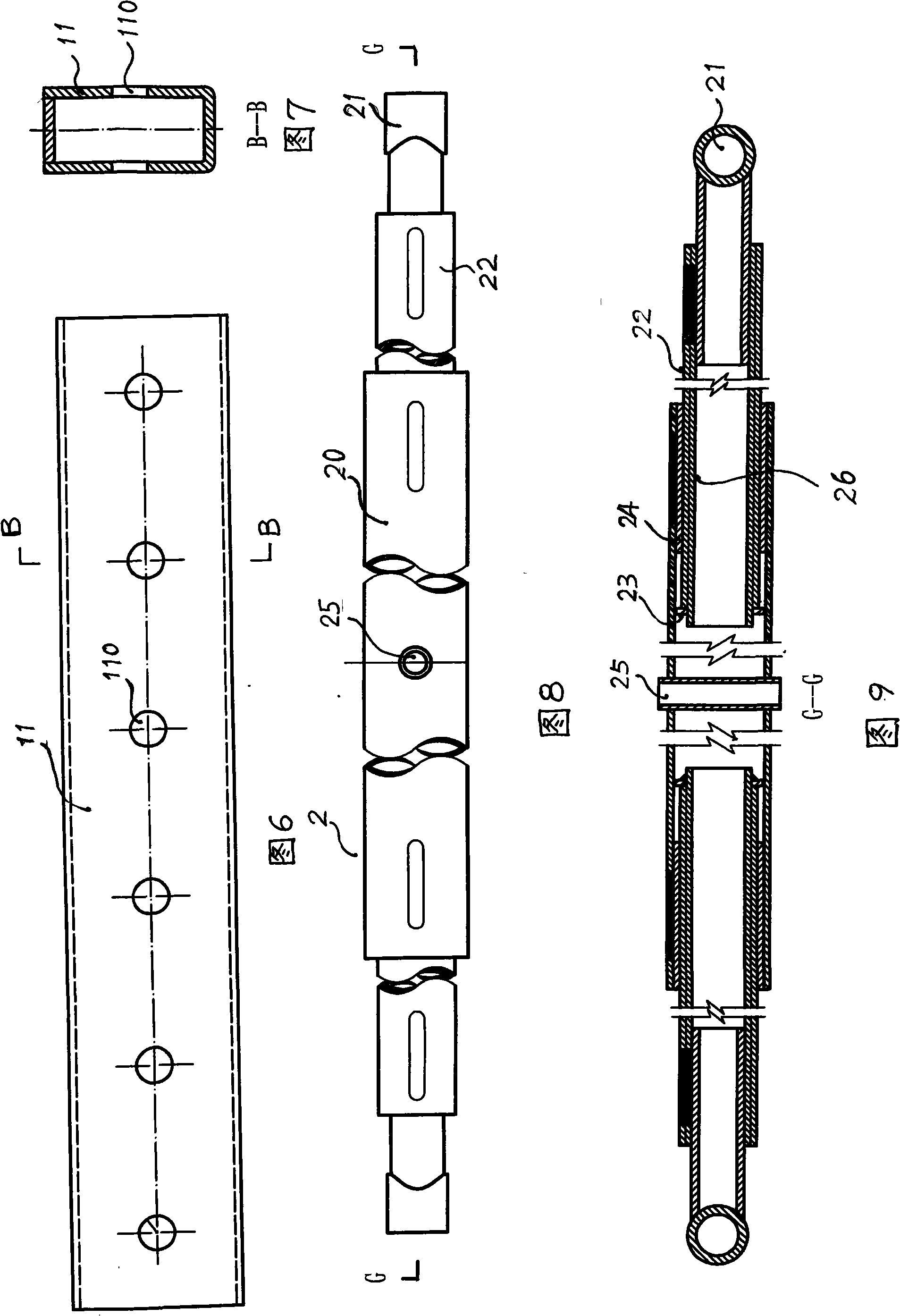

[0029] The truss assembly kit for constructing the above-mentioned different types of trusses includes chord components and their joints, web components, and node connection components. The rod body 10 of its chord part 1 is opposite to each other by two backs Shaped angle steel or "["-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com