Image comparison physical foaming gasket and preparation method thereof

A technology of physical foaming and image ratio, applied in chemical instruments and methods, cards for carrying information, sustainable manufacturing/processing, etc. Simple, easy to verify, and eliminate the effect of the use of glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

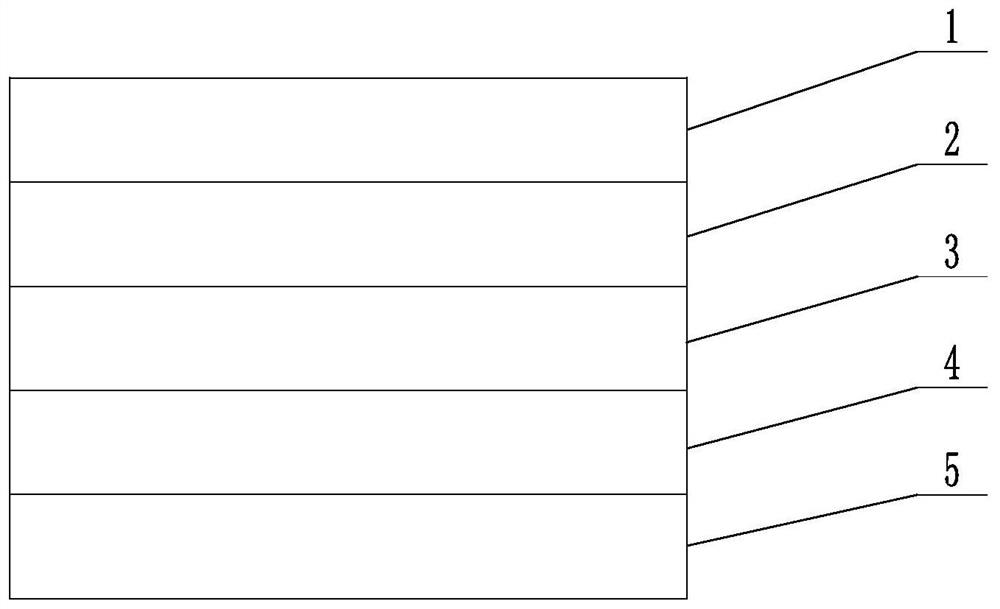

[0040] The preparation method of the described image comparison physical foam gasket, the specific steps are as follows:

[0041] 1) Choose a BOPP film with a thickness of 40 μm.

[0042] 2) On the BOPP film, use a flexo printing machine to position and print UV varnish with metal particles, dry it by UV lamp drying, and then position and print two-dimensional code information to form a printing layer 4; the color of metal particles can be selected A variety of colors can also be used, and the addition ratio of metal particles in the varnish is 5.3%.

[0043] 3) The BOPP film of the printed layer 4 is prepared, and the collector is used to collect pictures and associate them. The collected information forms a data folder, and the collected pictures are uploaded to the server to establish a relationship between the pictures and the QR code.

[0044] 4) The BOPP film of the printed layer 4 is bonded together with the physical foaming material by coating the PE film. When coatin...

Embodiment 2

[0049] The preparation method of the described image comparison physical foam gasket, the specific steps are as follows:

[0050] 1) Choose a single-sided corona BOPP film with a thickness of 30 μm.

[0051] 2) Use a digital machine to print random particles and two-dimensional code information on the BOPP film to form a printing layer 4 . There is a 1mm gap between the two-dimensional code and the random particle printing area to ensure that the random particle points do not affect the grade of the two-dimensional code and ensure the reading rate.

[0052] 3) The BOPP film of the printed layer 4 is prepared, and the collector is used to collect pictures and associate them. The collected information forms a data folder, and the collected pictures are uploaded to the server to establish a relationship between the pictures and the QR code.

[0053]4) The BOPP film of the printed layer 4 is bonded together with the physical foaming material by coating the PE film. When coating, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com