Method for creating vector holographic geometrical curves relevant to laser etching

A technology of geometric curve and production method, applied in the field of vector holographic geometric curve production, can solve the problems of sawtooth, insufficient refresh frequency, insufficient exposure speed, etc., and achieve the effect of shortening the plate-making cycle, obvious macro effect, and high anti-counterfeiting level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing, and the structure and principle of this device are very clear to those skilled in the art. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

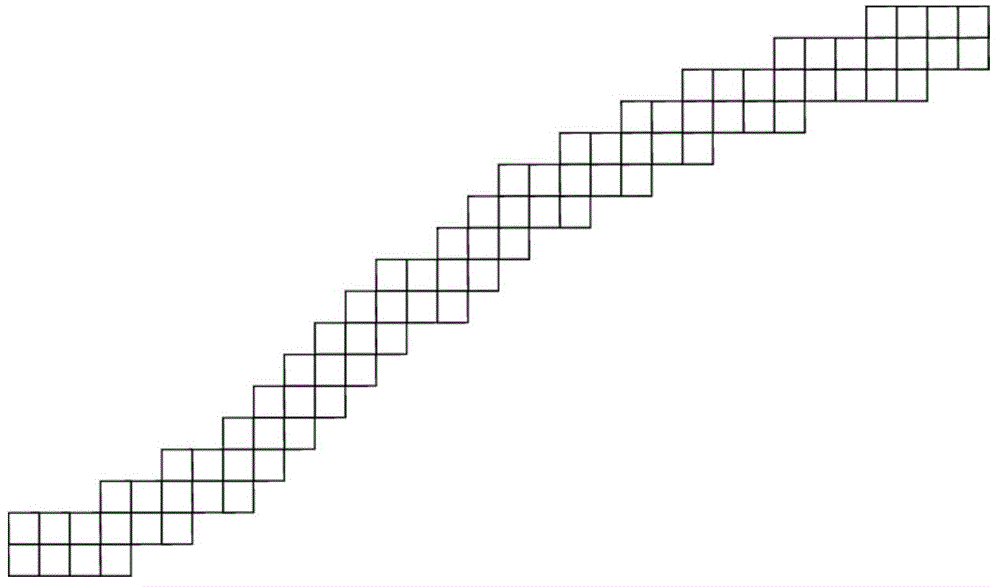

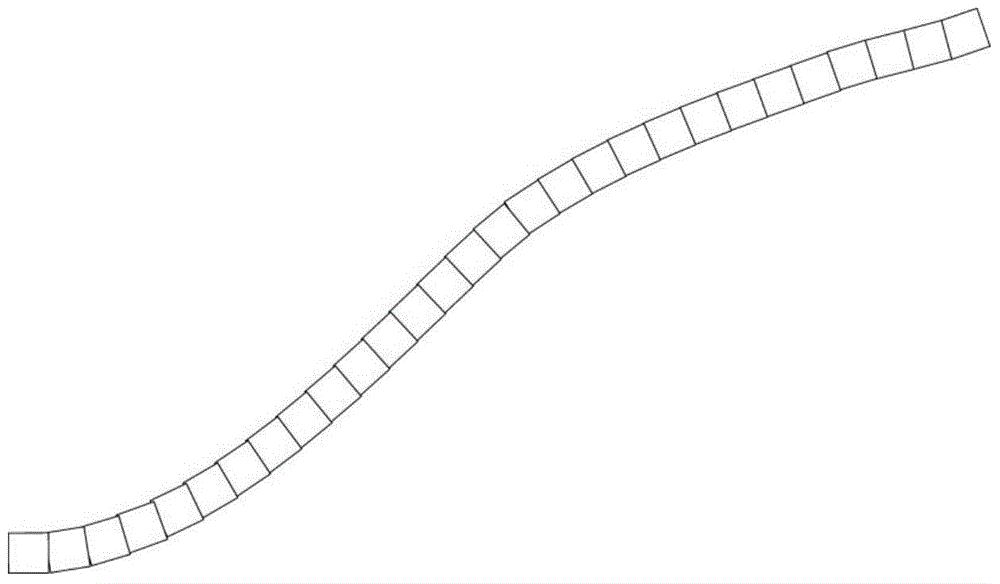

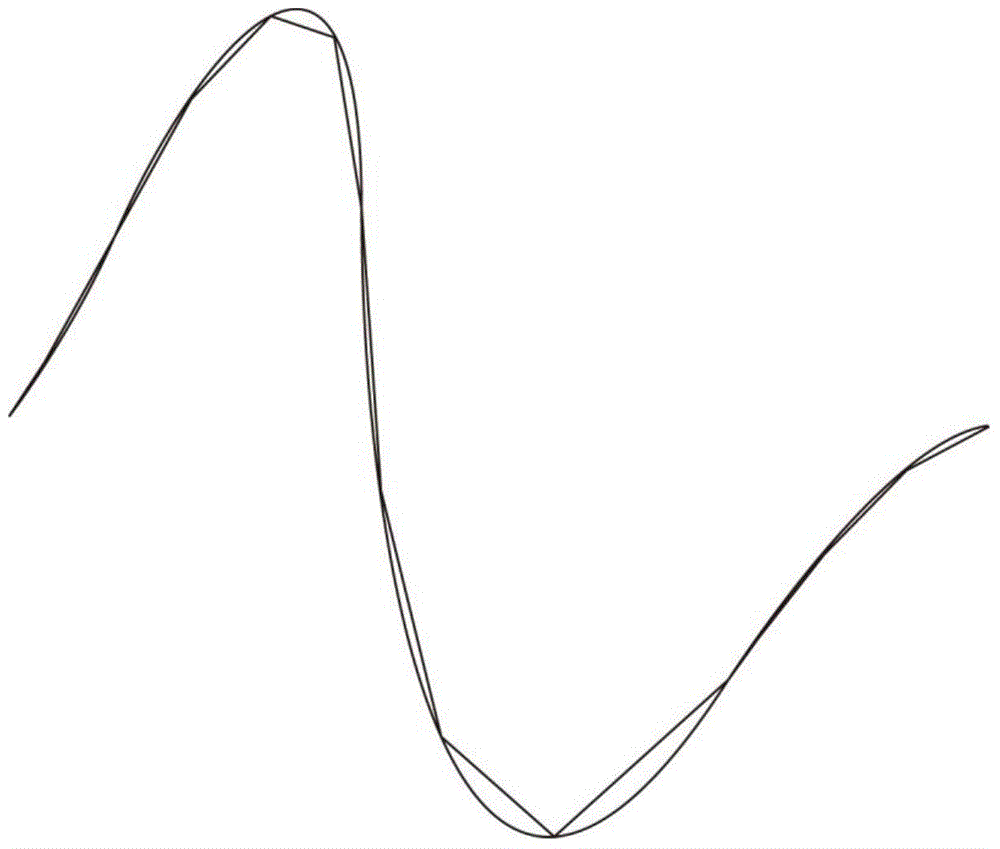

[0027] The method for making a vector holographic curve proposed by the present invention is mainly used in the fields of holographic anti-counterfeiting and product packaging. Its design principle is based on the Bezier curve function, such as image 3 As shown, through multiple iterative operations and converting it into a file in a special format, it is realized by using a holographic plate-making system and laser etching technology, such as Figure 4 shown. The holographic plate-making system is a technology that uses the principle of holography to make a hologram master, including rainbow holographic technology, optical informa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com