Image comparison physical foam gasket and preparation method thereof

A technology of physical foaming and image ratio, applied in chemical instruments and methods, cards for carrying information, sustainable manufacturing/processing, etc. Simple, easy to verify, and eliminate the effect of the use of glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

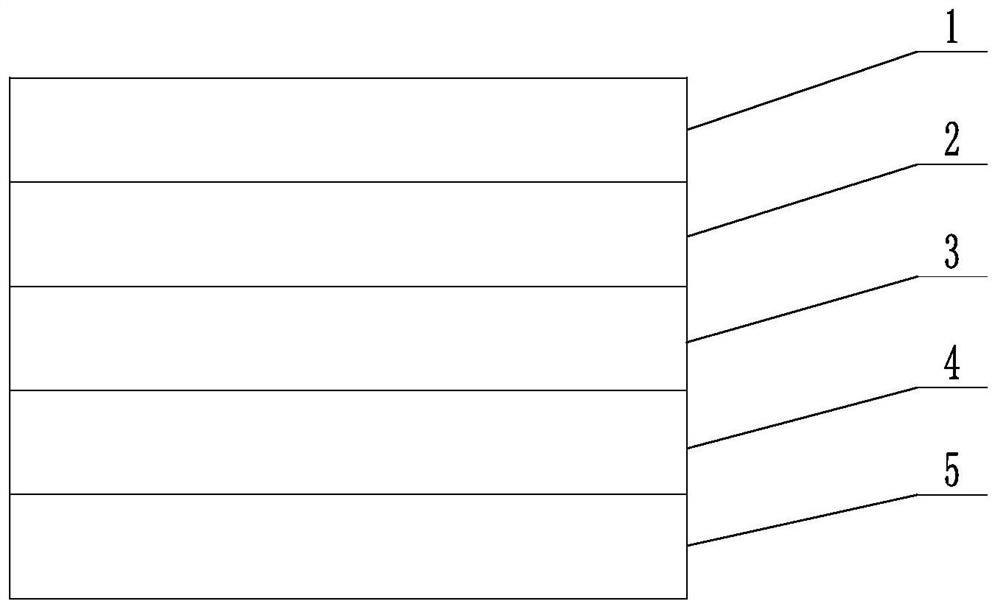

[0040] The preparation method of the described image comparison physical foam gasket, the specific steps are as follows:

[0041] 1) Select a BOPP film with a thickness of 40 μm.

[0042] 2) Use the flexo printing machine to position and print the UV varnish with metal particles on the BOPP film, dry it by UV lamp drying, and then position and print the two-dimensional code information to form the printing layer 4; the color of the metal particles can be One can also use a variety of colors, the addition ratio of metal particles in the varnish is 5.3%.

[0043] 3) The BOPP film of the printed layer 4 is prepared, and the collector is used to collect images, the collected information forms a data folder, and the collected images are uploaded to the server to establish an association relationship between the images and the two-dimensional code.

[0044] 4) Bond the BOPP film of the prepared printing layer 4 with the physical foam material by coating the PE film. When coating th...

Embodiment 2

[0049] The preparation method of the described image comparison physical foam gasket, the specific steps are as follows:

[0050] 1) Choose a single-sided corona BOPP film with a thickness of 30 μm.

[0051] 2) Using a digital machine to print random particles and two-dimensional code information on the BOPP film to form a printing layer 4 . There is a 1mm gap between the two-dimensional code and the random particle printing area to ensure that the random particle points do not affect the grade of the two-dimensional code and ensure the reading rate.

[0052] 3) The BOPP film of the printed layer 4 is prepared, and the collector is used to collect images, the collected information forms a data folder, and the collected images are uploaded to the server to establish an association relationship between the images and the two-dimensional code.

[0053]4) Bond the BOPP film of the prepared printing layer 4 with the physical foaming material by coating the PE film. When coating th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com