A kind of composite core and preparation method thereof

A technology of composite core and thermoplastic polymer, which is applied in the field of composite core, can solve the problems of irreparable damage, high maintenance cost, and non-recyclability of thermosetting composite core, and solve the problem of non-recyclability. The effect of low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

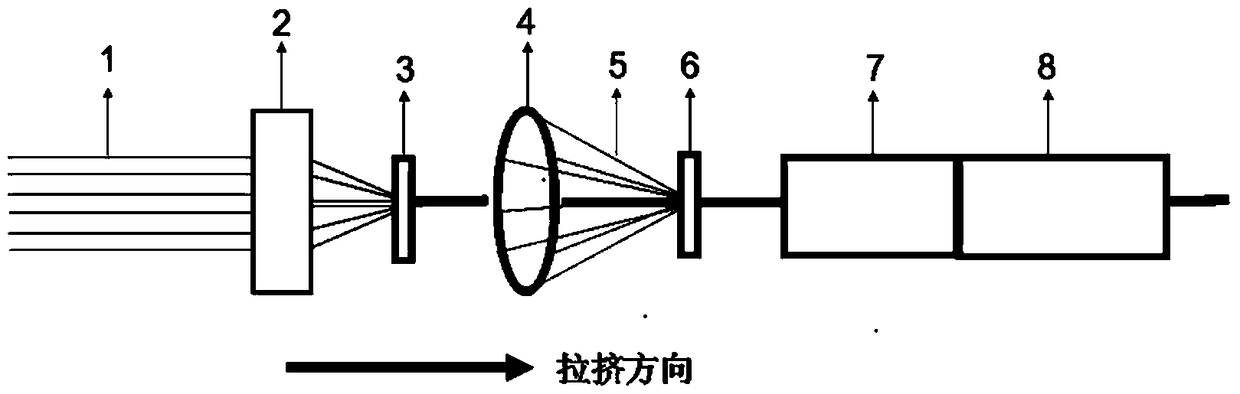

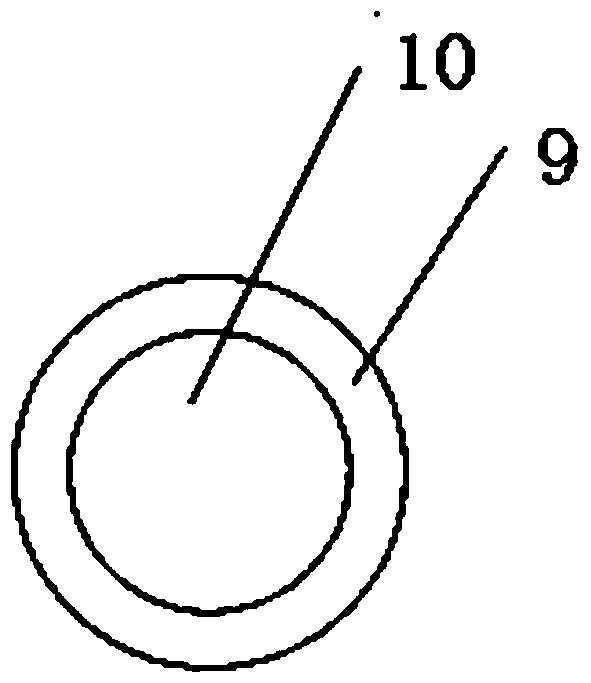

[0027] In addition, in a specific embodiment, a composite core preparation method, the method steps include: 1) carbon fiber and thermoplastic polymer nanofiber blended yarn is gathered into a carbon fiber circular rod through a cluster; 2) carbon fiber circle Wrap the glass fiber and thermoplastic polymer nanofiber blended yarn on the shaped rod and cool it to get the finished product.

[0028] Preferably, in a specific embodiment, the step 1) carbon fiber and thermoplastic polymer nanofiber blended yarn tow 1 is dried by a dryer 2, and then pultruded outward through a carbon fiber core layer collector 3 The carbon fiber round rod body.

[0029] Preferably, in a specific embodiment, the step 2) uses the tow guide 4 to introduce the glass fiber and thermoplastic polymer nanofiber blended yarn tow 5 into the glass fiber layer collector 6 to form The fiber layer is wrapped around the carbon fiber round rod body, and then enters the high-temperature molding mold zone 7 to melt a...

Embodiment 1

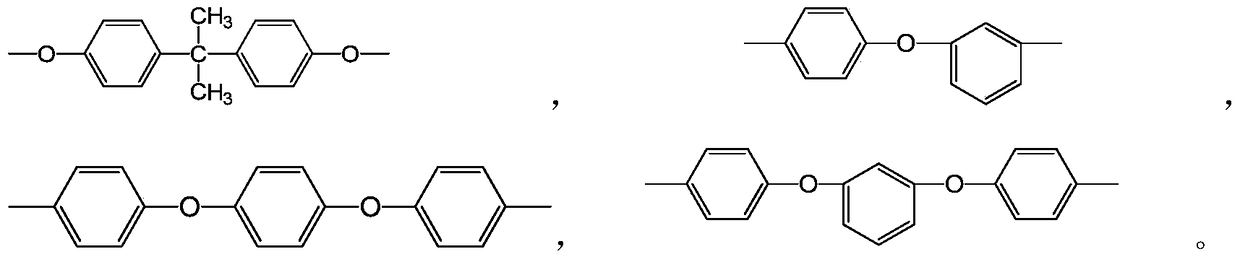

[0035] Choose composite core preparation raw material, by volume percentage, the blended fiber yarn of 65% carbon fiber and 35% thermoplastic polyetherimide (PEI) nanofiber, the blending of 65% glass fiber and 35% thermoplastic polyetherimide nanofiber yarn. Among them, the diameter of PEI nanofiber is 350nm, and the molecular chain of PEI includes the following structure:

[0036]

[0037] The glass transition temperature of PEI is 199°C, the initial decomposition temperature is 539°C, the tensile strength is 94MPa, the tensile modulus is 3.2GPa, and the elongation at break is 5.2%. Its properties meet the requirements of composite core matrix materials.

[0038] After the carbon fiber and thermoplastic polymer nanofiber mixed fiber yarn tow 1 is dried by the dryer 2, it is pultruded outward through the carbon fiber core layer collector 3 to form a carbon fiber round rod; After fiber and thermoplastic polymer nanofiber blended yarn tow 5 is introduced into the glass fiber...

Embodiment 2

[0043]Select the composite core preparation raw material, by volume percentage, the blended yarn of 60% carbon fiber and 40% thermoplastic polyetherimide (PEI) nanofiber, the blending of 60% glass fiber and 40% thermoplastic polyetherimide nanofiber yarn. Among them, the diameter of PEI nanofiber is 350nm, and the molecular chain of PEI includes the following structure:

[0044]

[0045] The glass transition temperature of PEI is 210°C, the initial decomposition temperature is 535°C, the tensile strength is 83MPa, the tensile modulus is 2.6GPa, and the elongation at break is 5.8%. Its properties meet the requirements of composite core matrix materials.

[0046] After the carbon fiber and thermoplastic polymer nanofiber mixed fiber yarn tow 1 is dried by the dryer 2, it is pultruded outward through the carbon fiber core layer collector 3 to form a carbon fiber round rod; After fiber and thermoplastic polymer nanofiber blended yarn tow 5 is introduced into the glass fiber la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com