Energy-saving environment-friendly treatment system for recycling of waste metal paint buckets

An energy-saving, environmentally friendly, metal-wasting technology, applied in the direction of incinerators, combustion types, combustion methods, etc., can solve the problems of occupying sites and warehouses, restricting the development space of enterprises, and affecting the business expansion of industries, so as to achieve full reuse of energy, saving and reducing Effect of Exhaust Gas Treatment Costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

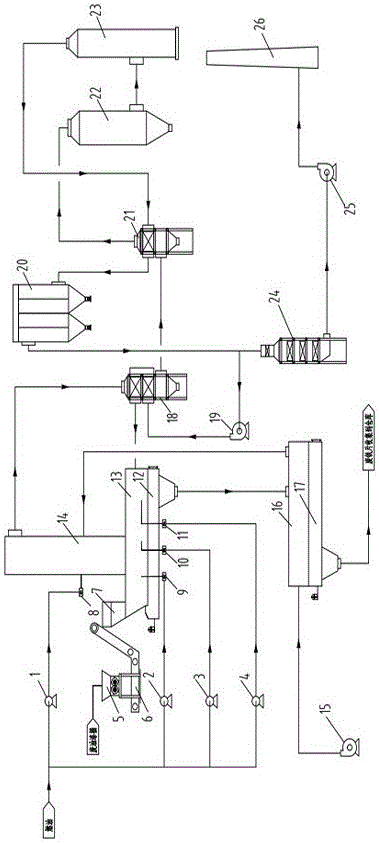

[0019] An energy-saving and environment-friendly treatment system for recycling waste metal paint buckets. The automatic feeding system is connected to the pyrolysis system. The pyrolysis system is respectively connected to the scrap iron recovery system and the incineration system. The scrap iron recovery system is also connected to the incineration system. The incineration system is also connected with the waste heat utilization system, the waste heat utilization system is also connected with the quenching system, the quenching system is also connected with the deacidification system, the deacidification system is also connected with the dust removal system, and the dust removal system is respectively connected with the waste heat utilization system and the denitrification system. Also connected to the fume extraction system. The pyrolysis system includes oil pump 2# (2), oil pump 3# (3), oil pump 4# (4), burner 2# (9), burner 3# (10), burner 4# (11) , pyrolysis grate (12), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com