Patents

Literature

39results about How to "Strong wetting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Powerful cleaning agent

InactiveCN105273861AEasy to useSafe storageInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSide effectAlcohol

The invention relates to a powerful cleaning agent and belongs to the field of fine chemical automotive chemicals. The cleaning agent is prepared from surface active agents, alcohol additives, oiliness additives, auxiliary agents and water. The surface active agents and the oiliness additives play roles of solubilization, dissolving and washing, the alcohol additives jointly act with the two mentioned components for forming stable microemulsion and have certain permeation, moistening and dissolving functions, the three components jointly act so that the cleaning agent can achieve a good cleaning effect, and the auxiliary agents are functional additives. The cleaning agent has no side effect on cast iron, cast aluminum, leather, fabric, rubber, plastic and the like and can effectively clean an engine or the surface of the interior without generating phenomena of corrosion, color fading, bubbling, falling and the like.

Owner:蚌埠市神丰贸易有限公司

Bactericidal and anti-bacterial type tableware detergent

InactiveCN104152287AExpand the antibacterial spectrumImprove sterilization and antibacterialOrganic detergent compounding agentsNon-ionic surface-active compoundsChemistryCarboxylate

The invention provides a bactericidal and anti-bacterial type tableware detergent. The bactericidal and anti-bacterial type tableware detergent is prepared from the following raw materials by weight: 11%-16% of sodium fatty acid methyl ester sulfonate, 8%-12% of alcohol ether carboxylate, 6%-11% of alkyl glycoside, 4%-8% of a bamboo vinegar liquid, 3%-6% of coconut oil fatty acid monoethanolamide, 3%-5% of jasmine extract, 1%-3% of tea saponin, 1%-3% of sodium polyaspartate, 0.8%-3.0% of sodium gluconate, 0.5%-2.5% of salt, and the balance being distilled water. The tableware detergent provided by the invention has significant bactericidal and anti-bacterial effects, can be degraded easily, is safe, environment-friendly and mild, as a maintenance effect for skins, and does not damage the skins.

Owner:周可幸

Waterproof coating of carton

ActiveCN102704330AGood chemical stabilityImprove insulation performanceCoatingsPaper forming aids additionParaffin waxEmulsion

The invention relates to a waterproof coating, in particular to a waterproof coating of a carton, which comprises the following components in weight part: 30-120 parts of paraffin micro-emulsion, 50-90 parts of simethicone, and 4-8 parts of emulsifier. The waterproof coating is prepared according to a method as follows: (1) heating the paraffin micro-emulsion to 50-180 degree C; (2) adding simethicone and stirring for 0.5-3 hours; and (3) adding the emulsifier, stirring at a high speed for 10-40 minutes, and cooling to the room temperature. The waterproof coating of the carton, disclosed by the invention, has no pollution on the human body and the environment, can be combined with the base material firmly, and has excellent waterproof property.

Owner:ANHUI JINDUN PAINT

Pollution-free production process of plant fiber pulp

InactiveCN102108644AStrong wettingImprove permeabilityPulp de-wateringFibrous raw materialsFiberSlurry

The invention provides a pollution-free production process of plant fiber pulp. The method is characterized by obtaining the bleached fine pulp with concentration being 30-40% through coarse pulp preparation, defibrination treatment, desanding treatment, screening treatment, concentration and shoving treatment. The process has the following beneficial effects: the auxiliary has strong wetting and infiltrating functions, promotes the sodium hydroxide to rapidly wet the surface of the fibers and be infiltrated into the fibers with the reactive agent generated by hydrogen peroxide in the presence of the decomposing agent and ensures the chromophore in the lignin to be decomposed into low molecular colorless substances while the lignin is degraded and dissolved out; the stabilizing agent can complex and shield chromogenic metal ions and is characterized by reducing generation of the chromophoric groups, thus improving the whiteness of the pulp; under the action of the surfactant in the auxiliary, the dissolved lignin, colloid and the like can be uniformly dispersed in the water to be prevented from being adsorbed by the plant fibers again; and the pulp washing and bleaching procedures are omitted in the method, and at the same time, the waste water in the pulping process can be fully reused through simple treatment, thus not producing pulping back liquor causing serious pollution.

Owner:深圳市美中现代科技发展有限公司

High-efficiency low-foam phosphorus-free sterilizing tableware cleanser applicable to large-scale machine washing

InactiveCN101921670APromote decompositionQuick breakdownInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsSodium metasilicatePolyethylene glycol

The invention relates to a high-efficiency low-foam phosphorus-free sterilizing tableware cleanser applicable to large-scale machine washing, which is mainly prepared from sodium metasilicate, sodium peroxycarbonate, sodium dodecyl benzene sulfonate, polyethylene glycol (400), alkylphenol ethoxylate, fatty alcohol-polyoxyethylene ether, tetrasodium ethylenediamine tetraacetate and sodium hydroxide. The tableware cleanser has the characteristics of no phosphorus, sterilization, high washing capability, simple operation, no chlorine residue and the like. The tableware cleanser is an ideal machine washing cleanser applicable to enterprises engaging in concentrated tableware washing, such as hotels, hospitals, restaurants, pubs, dining halls and the like.

Owner:SHANDONG UNIV OF SCI & TECH

Probiotic enzymatic composition capable of regulating intestinal tract and application thereof

InactiveCN108968058ASignificant effectPrevent indigestionFood ingredient functionsSide effectDietary fiber

The embodiment of the invention discloses a probiotic enzymatic composition capable of regulating intestinal tract. The composition is prepared by mixing the following raw materials in percentage by weight: 65 to 75 percent of dietary fiber, 10 to 15 percent of comprehensive vegetable and fruit enzymatic powder, 10 to 15 percent of soybean protein powder, 2.5 to 4.5 percent of probiotic bacteria,1 to 2 percent of plant protease, 0.3 to 0.8 percent of soybean phospholipid, 0.5 to 0.8 percent of an acidifier and 0.08 to 0.15 percent of a sweetener. The probiotic enzymatic composition provided by the invention has a remarkable curative effect in regulating intestinal problems, can effectively prevent dyspepsia and improve constipation, and has the functions of protecting intestinal mucosa and enhancing immunity, thereby fundamentally solving intestinal problems. The composition provided by the invention is natural, free from side effects, and safe and effective in use, and has a broad market application prospect.

Owner:广州乔媛商贸有限公司

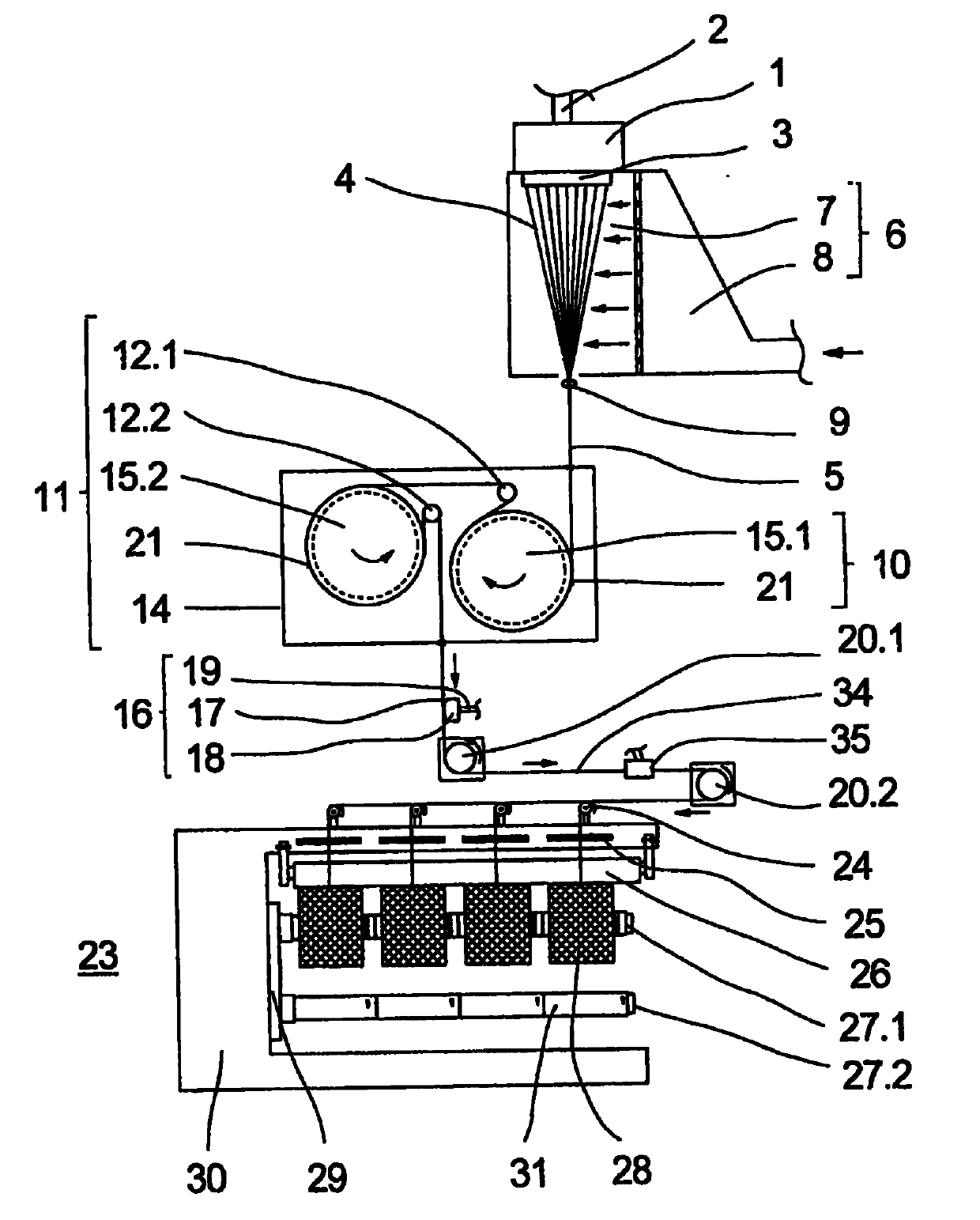

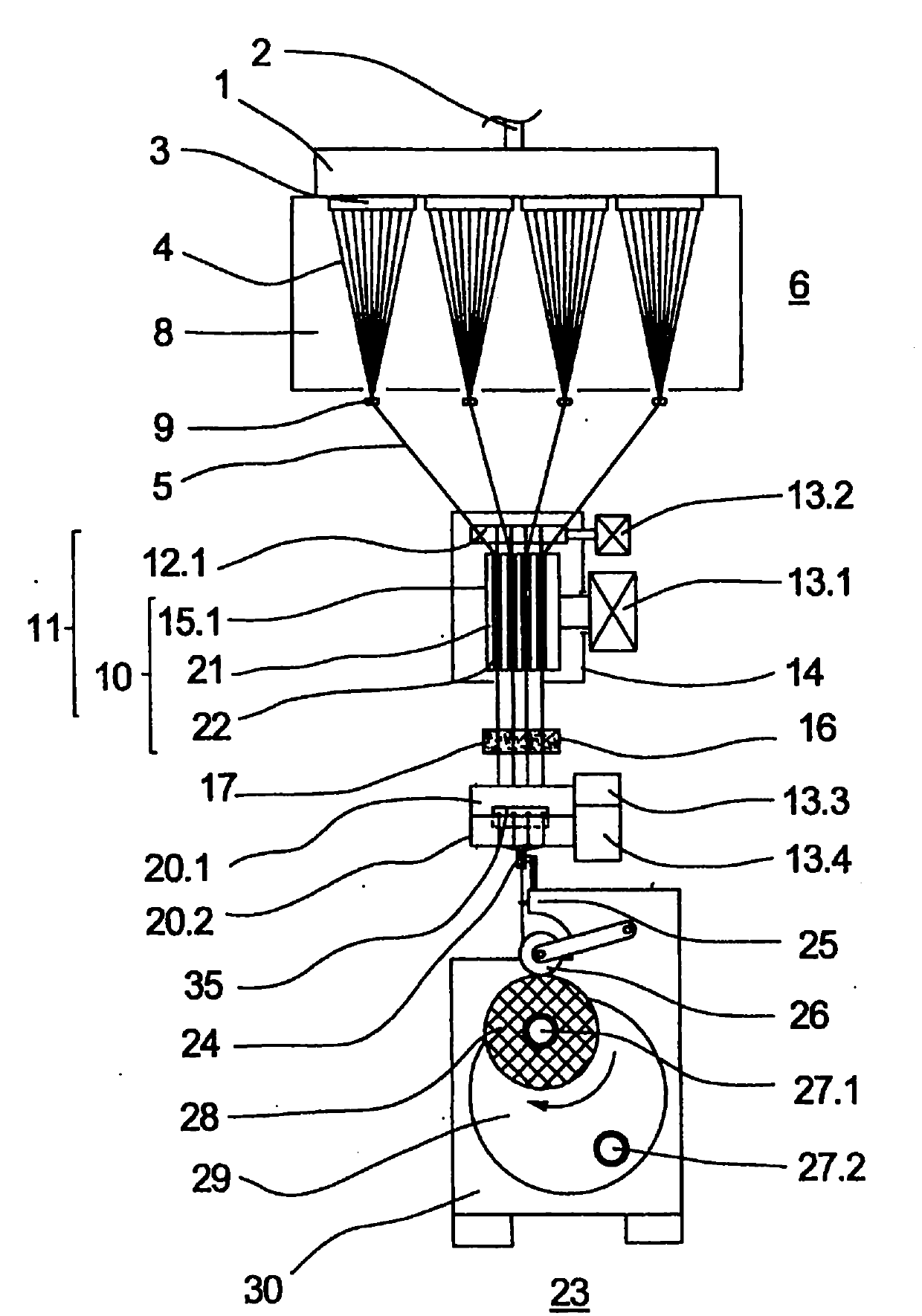

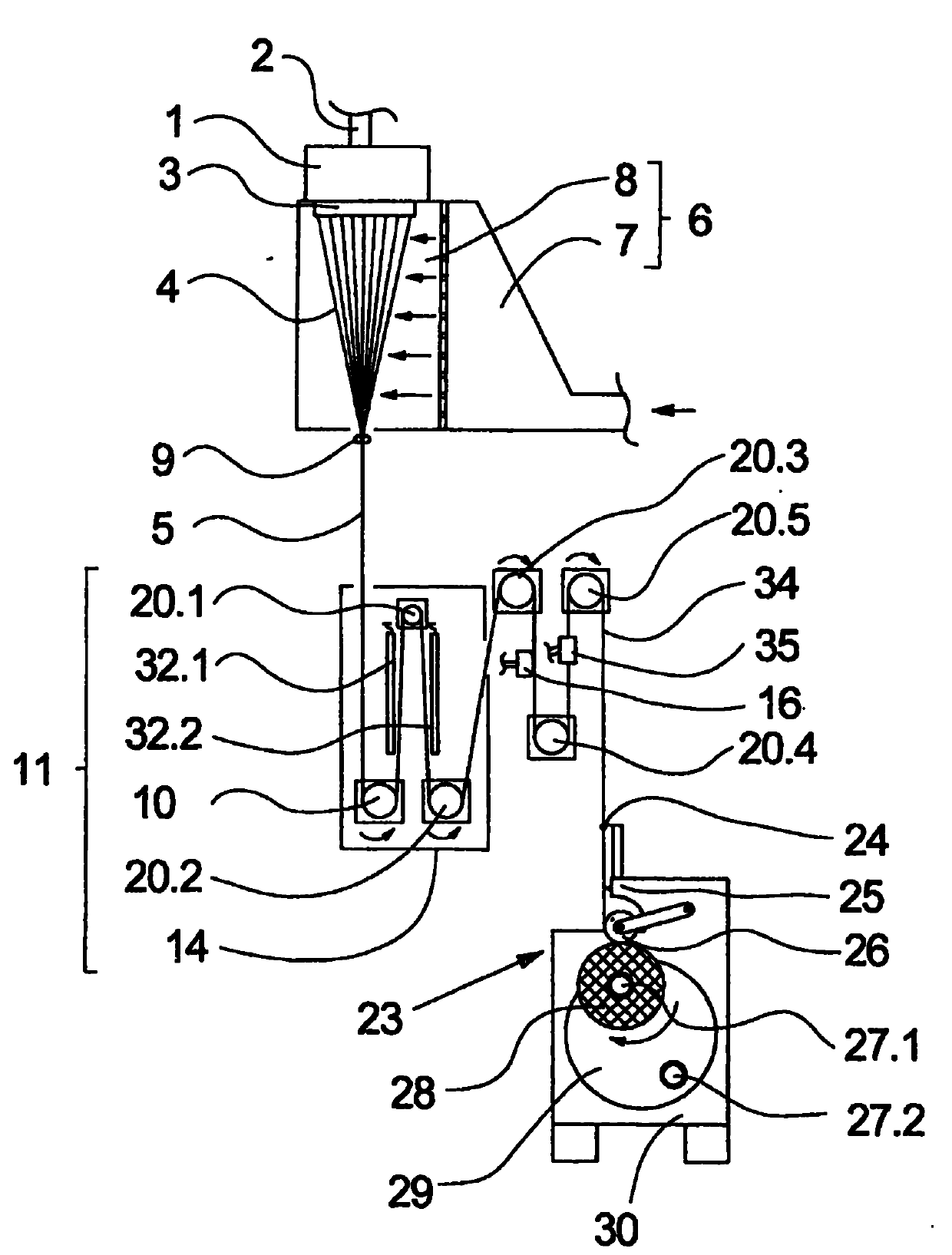

Method for melt-spinning, drawing, and winding up a multifilament, and apparatus for carrying out said method

ActiveCN102016138AIncrease yarn speedEvenly distributedArtificial thread manufacturing machinesFilament manufactureYarnGlass transition

The invention relates to a method for melt-spinning, drawing, and winding up a multifilament to form a fully drawn yarn (FDY) as well as an apparatus for carrying out said method. According to the invention, first, a plurality of filaments is extruded from a thermoplastic melt, is cooled to a temperature lying below the glass transition temperature of the thermoplastic material, and is combined into a filament bundle without feeding a finishing fluid. The filament bundle is then taken up at a speed exceeding 1,500 m / min, is heated to a temperature exceeding the glass transition temperature of the thermoplastic material, and is drawn at a drawing speed exceeding 4,000 m / min. The filament bundle is then finished using a finishing fluid, and the thread is wound up into a package. According to the invention, the finishing device is arranged in a thread running zone between the drawing device and the winding device of the apparatus, the thread having a thread running speed exceeding 4,000 m / min in said zone. The method and apparatus according to the invention thus form an energetically optimized process for producing fully drawn yarns.

Owner:OERLIKON TEXTILE GMBH & CO KG

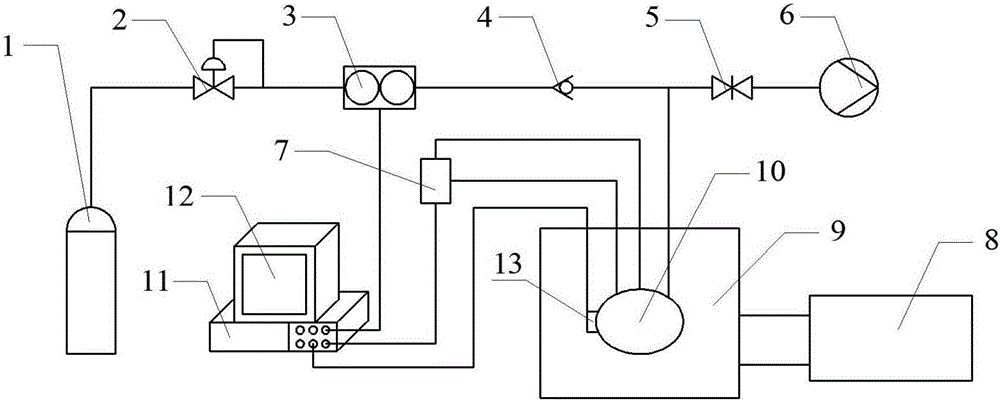

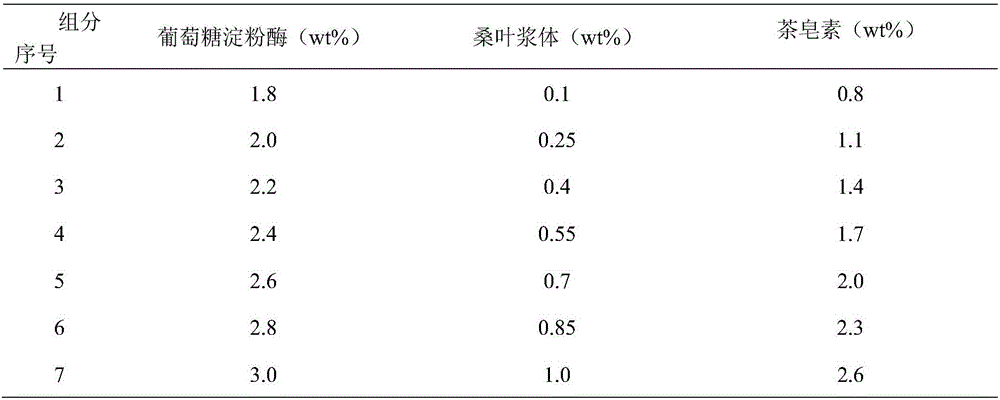

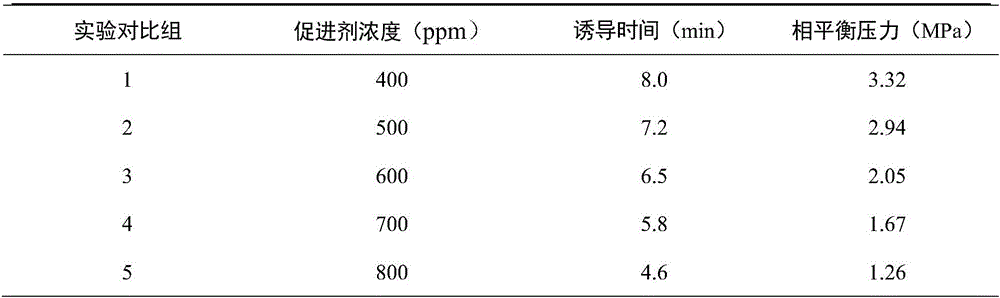

Gas hydrate accelerant and preparation method thereof

ActiveCN106543959AImprove economyNon-toxicOther chemical processesGaseous fuelsDistilled waterProduct gas

The invention relates to the technical field of natural gas hydrate production and utilization, in particular to a high-efficiency accelerant capable of strengthening natural gas hydrate formation and a preparation method thereof. The method includes: selecting dried mulberry leaves, performing grinding and sieving to obtain powder with a particle size of less than 0.3mm; mixing the mulberry leaf powder with distilled water according to a weight ratio of 1:15, conducting heating to 70DEG C, then performing stirring at a rotation speed of 800rpm for 10min to obtain a mulberry leaf slurry; weighing glucamylase, tea saponin, the mulberry leaf slurry and deionized water, conducting calculation by mass percentage content to prepare a mixed water solution with 1.8-3% of glucamylase, 0.8-2.6% of tea saponin and 0.1-1% of the mulberry leaf slurry; and heating the prepared mixed water solution to 40DEG C-50DEG C, and performing stirring in a stirring kettle for 60min so as to obtain the hydrate accelerant.

Owner:创科云涂节能新材料科技(苏州)有限公司

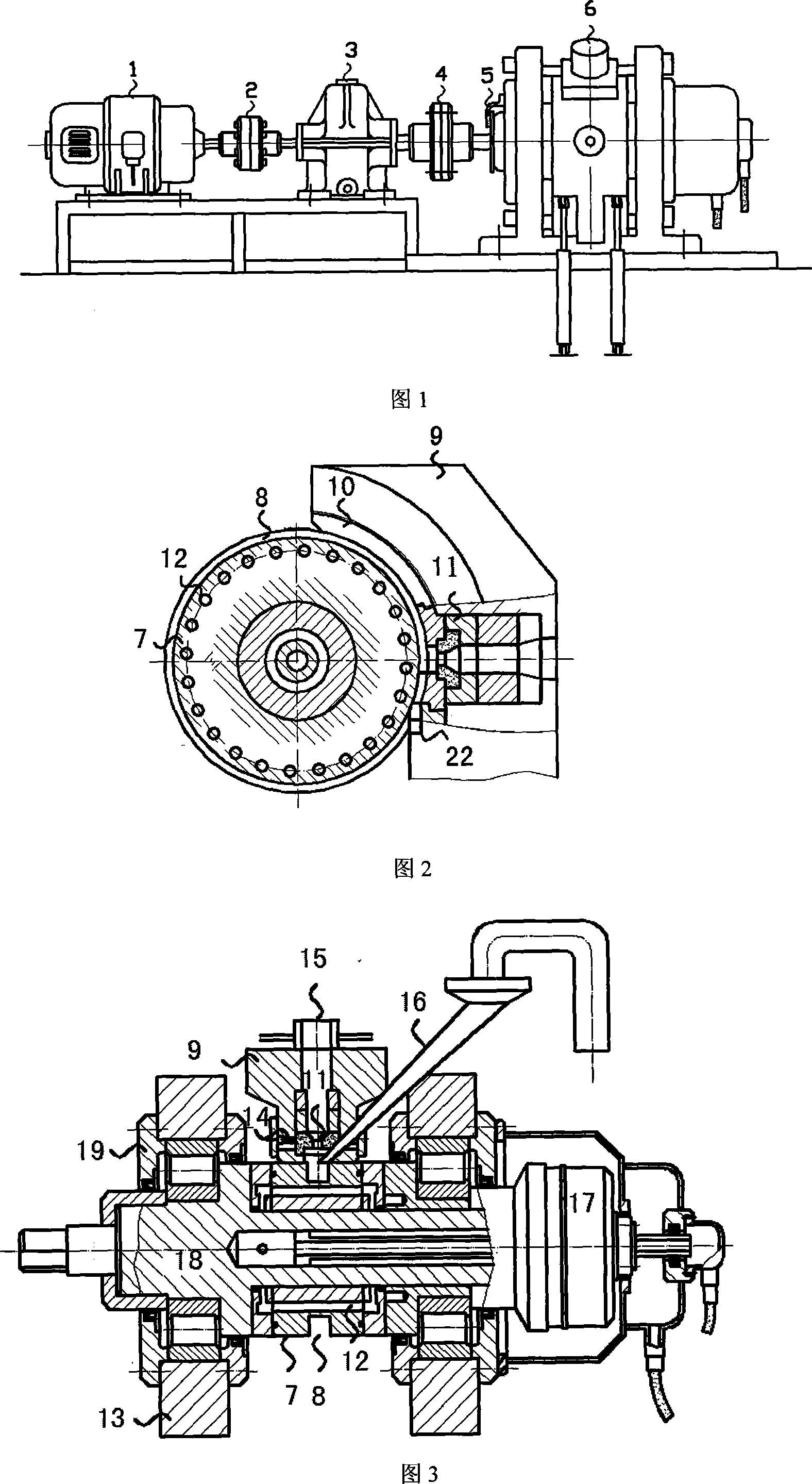

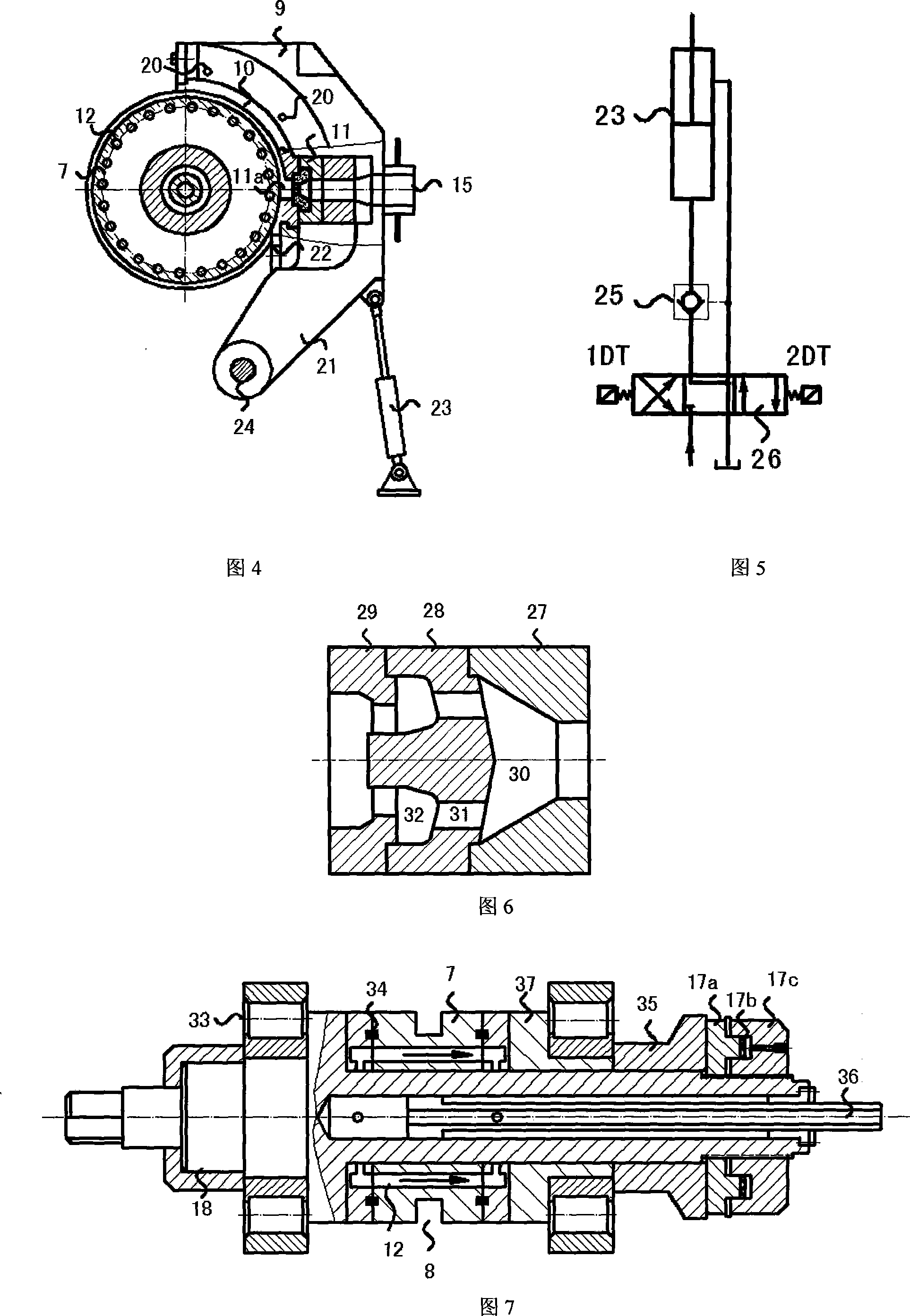

Aluminium magnesium alloy and its composite material continuously concreting and forming integrative device

The invention relates to an integral device for continuous concretion and forming for aluminum, magnesium alloy and compound materials of the aluminum and magnesium alloy consisting of a motor, a retarding machine, an elastic JB, a main machine and a frame. The invention is characterized in that the main machine consists of a water cooling wheel system, a fixing shoe seat, a die assembled in a mold cavity, a hydraulic drive pressure maintaining device and a speed and torque sensor arranged on a shaft head of the main machine. The water cooling wheel system is provided with a hollow shaft; a rotary roller is mounted on the water cooling wheel system and is pressed and sealed by a hydraulic nut. The fixing shoe seat is provided with a shoe seat body and the inner side of an arc surface of the shoe seat body is provided with a slot sealing block; the middle part is provided with the mold cavity provided with the die and a material blocking block is mounted below an opening of the mold cavity. Applying the invention can not only realize the continuous concretion and forming of the aluminum and magnesium alloy materials, but also can improve the intensities, crack tenacity and plasticity of the basic bodies of the aluminum and magnesium; simultaneously can realize the organic combination of concretion and expanding forming; can continuously produce the products of tubes, wires and proximate matters with infinite length, high performance and big dimension; and can reach energy and material saving as well as improve the use value of the products; is easy to realize industrialization.

Owner:NORTHEASTERN UNIV

Cleaning agent for aluminum alloy profile micro arc oxidation pretreatment and preparation method thereof

ActiveCN109136953AStable in natureExtended service lifeSurface reaction electrolytic coatingPlasma electrolytic oxidationMicro arc oxidation

The invention relates to a cleaning agent for aluminum alloy profile micro arc oxidation pretreatment and a preparation method thereof. The cleaning agent comprises 1.5-2.0g / L of sodium citrate, 2.6-2.8g / L of sodium metasilicate, 0.4-0.5g / L of sodium borate, 3.0-4.0g / L of diprophylene glycol, 0.8-1.0g / L of EDTA-2Na, 0.6-0.8g / L of fatty alcohol polyoxyethylene ether, 0.6-0.8g / L of alkylphenol polyoxyethylene ether, 0.3-0.4g / L of triethanolamine oleic soap and 0.6-0.8g / L of dodecyl dimethyl amine oxide. The alkaline water-based cleaning agent has stable and quick wash-deoiling ability, does notcorrode aluminum alloy profiles, is stable in property, high in oil stain assimilating capacity, good in deoiling effect, long in service life, free of strong acid, strong alkali and phosphorus element, low in cost, short in cleaning time and suitable for aluminum alloy profile micro arc oxidation pretreatment.

Owner:广东中联邦精细化工有限公司

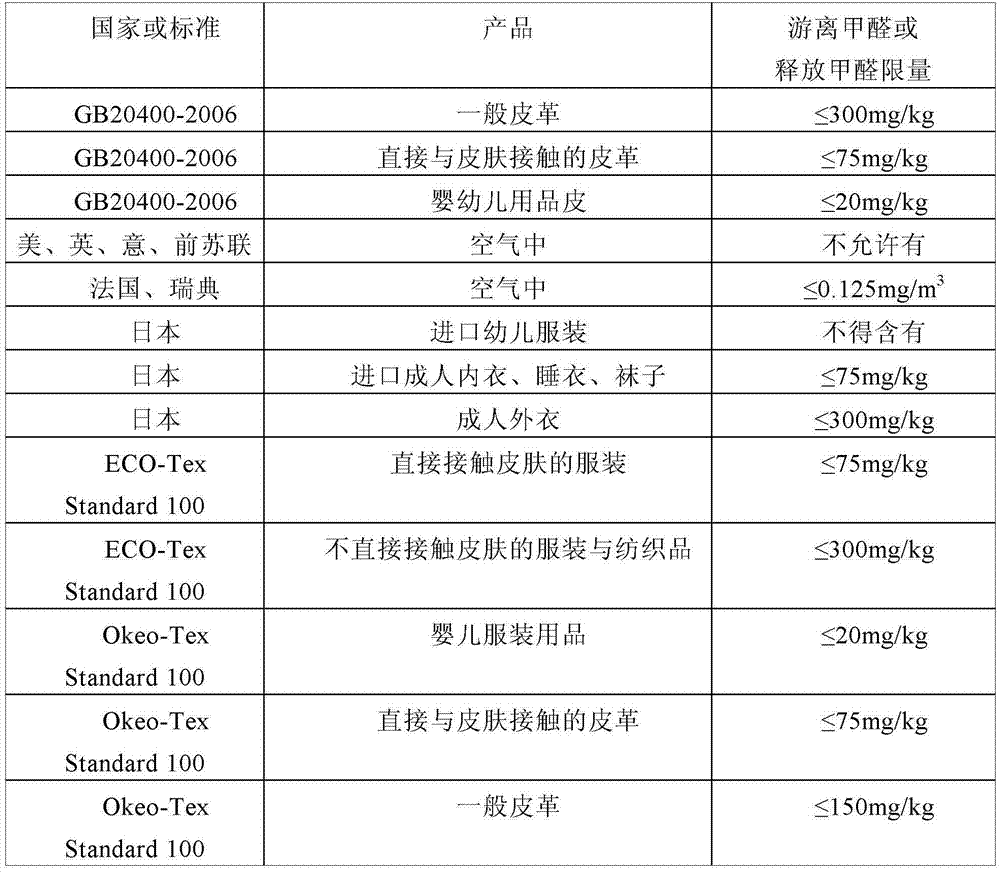

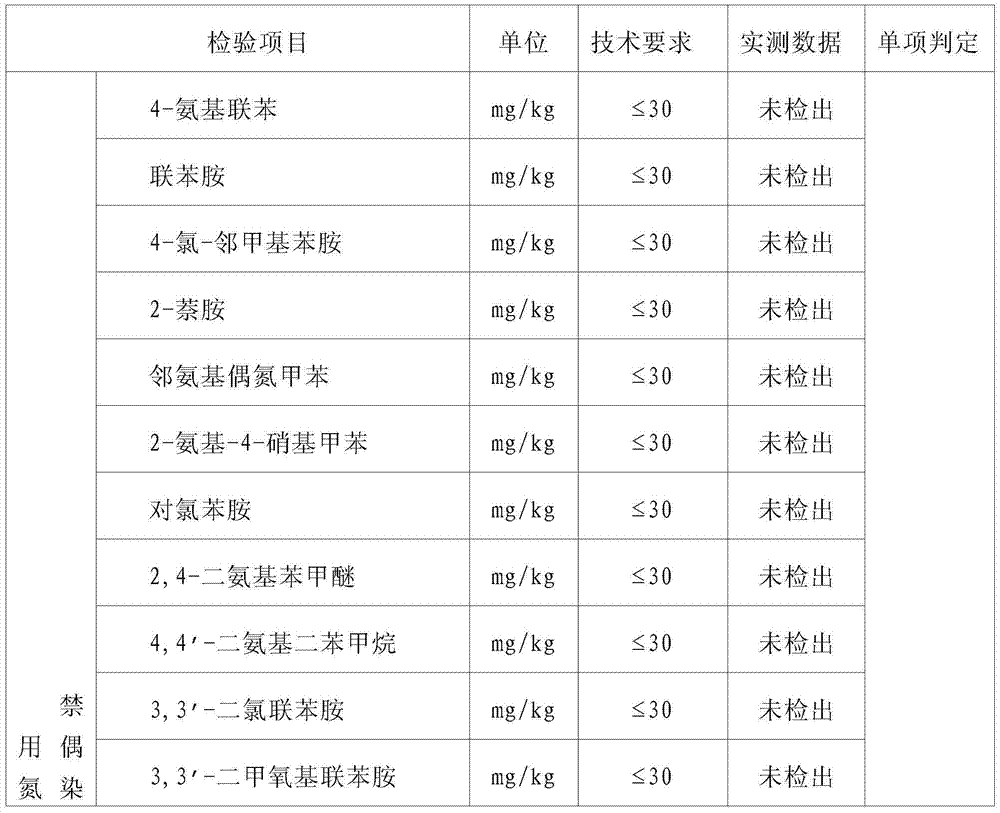

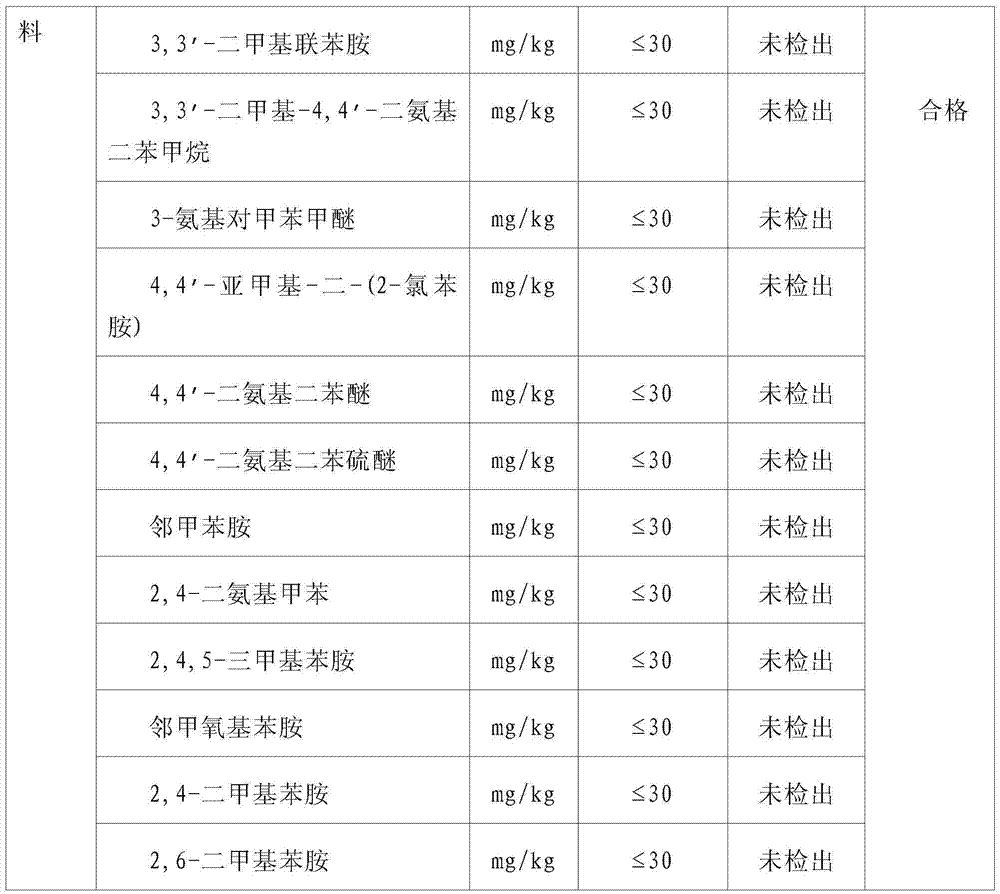

Fur free formaldehyde content reducing method

InactiveCN104726621AHelp removeImprove the effect of removing free formaldehyde in furTanning treatmentDyeing processChemistryAldehyde

The invention discloses a fur free formaldehyde content reducing method which comprises the following steps: 1) taking fur for weighing, and determining fur free formaldehyde content; 2) retanning for formaldehyde removal; 3) capturing to remove free formaldehyde; 4) washing to remove the free formaldehyde; 5) dye fixing; and 6) aldehyde fixing. The method can reduce the fur free formaldehyde content from about 450 mg / kg to 70 mg / kg or less, or even 20mg / kg or less, and the fur free formaldehyde content may not significantly rebound within three months.

Owner:ZHEJIANG ZHONGHUI FUR & LEATHER +1

Environmental-protection composite dust suppressant, and preparation method thereof

InactiveCN110396394ACause secondary pollutionStable film formationOther chemical processesSorbentAdsorption effect

The invention discloses an environmental-protection composite dust suppressant. The environmental-protection composite dust suppressant comprises following components, by weight, 40 to 60 parts of modified starch, 5 to 15 parts of a wetting agent, 0.5 to 5 parts of an adsorber, and 0.1 to 3 parts of a crosslinking agent. A preparation method comprises following steps: 1, modified starch preparation; 2, mixed raw material emulsion preparation; and 3, ultraviolet radiation reaction. The components are simple; effect is excellent; excellent biodegradability is achieved; no secondary environment pollution is caused; in the preparation method, high efficiency supersonic wave is adopted in starch modification firstly, and then grafting of an action component monomer and a surfactant onto the surface of starch is carried out, so that dust suppressant formed film is more strong, wetting and water adsorption effect is better and lasts long. The preparation method is simple, and is convenient tocontrol; production cost is low; the raw materials are easily available; the environmental-protection composite dust suppressant is friendly to the environment, and possesses a plurality of functionsincluding wetting capacity, bonding performance, and coagulation capacity, and is a multi-functional chemical dust suppressant.

Owner:江苏乐尔环境科技股份有限公司

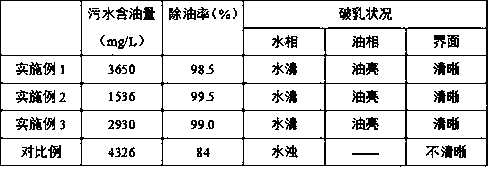

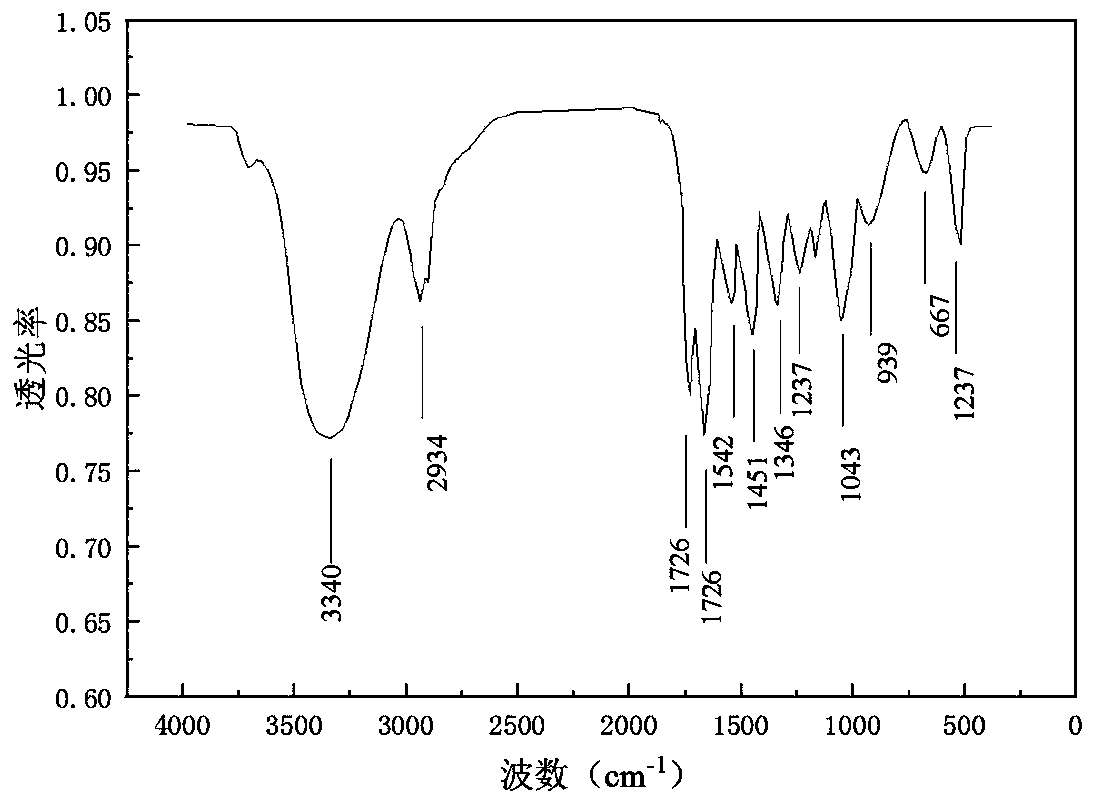

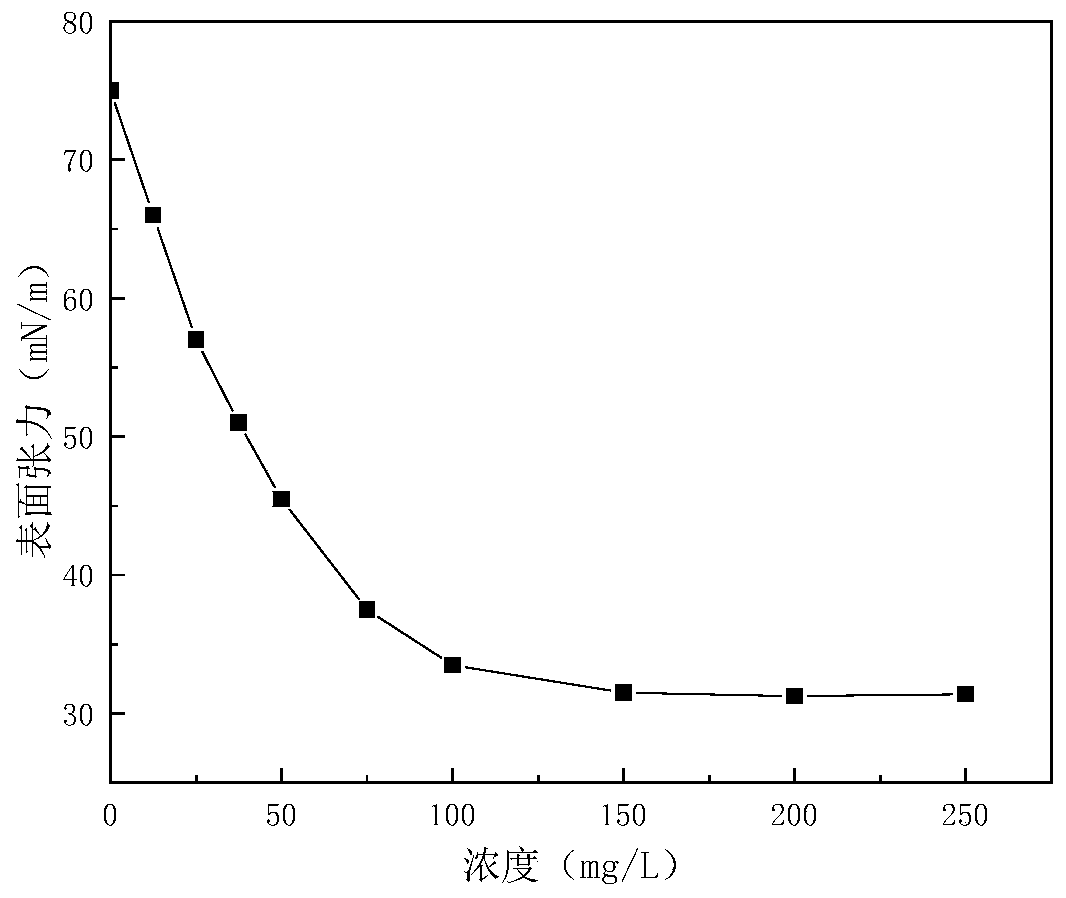

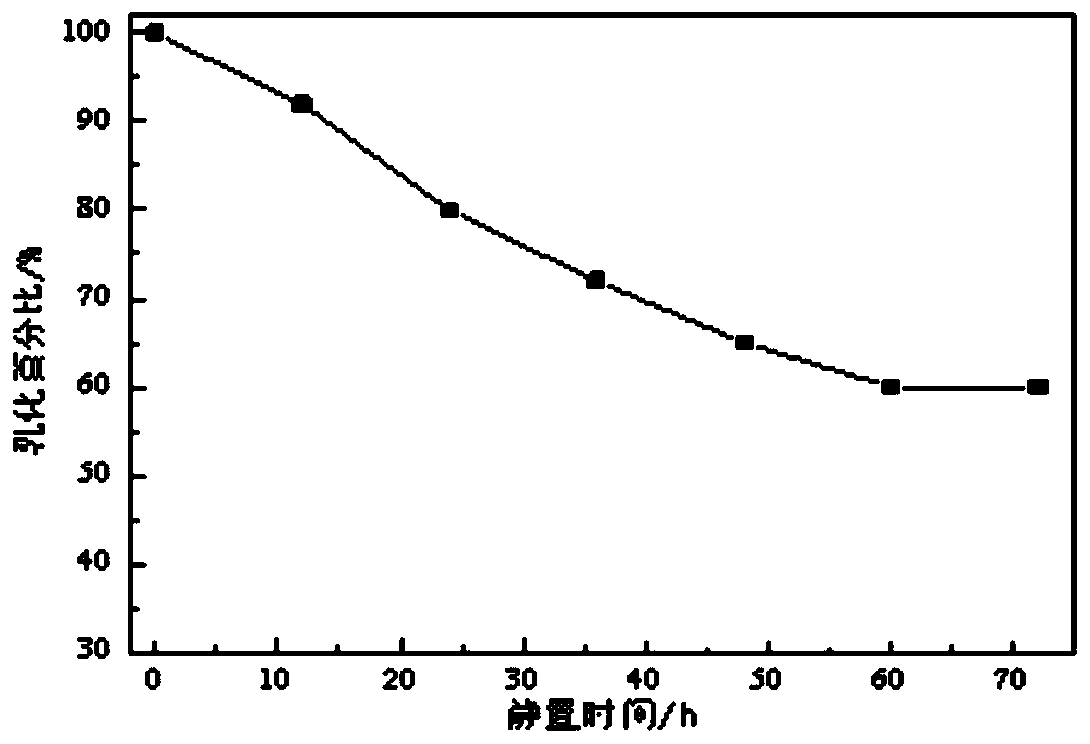

Preparation method of demulsifier

InactiveCN108641697AImprove adsorption capacityIncrease surface tensionDrilling compositionChemical industryPhenol

The invention discloses a preparation method of a demulsifier, and belongs to the technical field of chemical industry. According to the method disclosed by the invention, tert-butylphenol, formaldehyde and tetraethylenepentamine are used to prepare tert-butylphenol phenol amine resin; the tert-butylphenol phenol amine resin is used as an initiator; the tert-butylphenol phenol amine resin and propylene oxide are subjected to an anion ring-opening polymerization reaction to form a block polyether; and the block polyether has stronger wetting and replacing effects. When the block polyether withstronger surface activity replaces other emulsifiers, an interface film becomes loose, adsorption of block polyether molecules at a gas-liquid interface can be promoted, ability of the polyether to reduce surface tension of water can be improved, and micelles are easier to form in a bulk phase for the block polyether, so that more emulsifier molecules are replaced, better dehydration effects are achieved, and demulsification in the late stage is prepared. The method disclosed by the invention solves the problem that the crude oil is difficult to dehydrate because that a current chemical oil displacing agent makes a crude oil emulsion have good stability and makes a demulsifier have difficult demulsification.

Owner:黄智慧

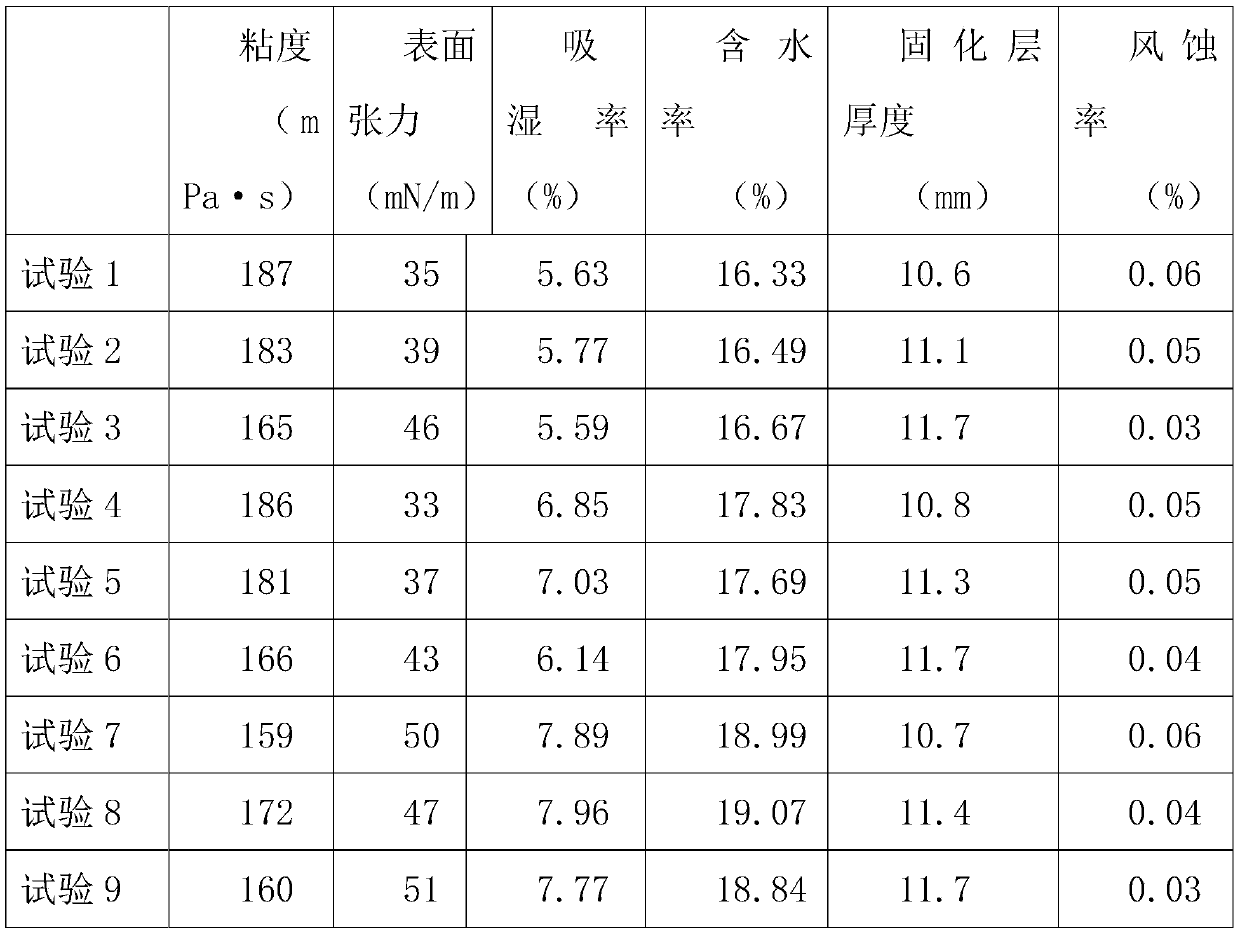

Natural waterborne paint ink and preparation method thereof

The invention relates to the technical field of preparation of school supplies, in particular to natural waterborne paint ink. The natural waterborne paint ink is made from, by weight, 15-25 parts of natural pigments, 3-5 parts of polygonum multiflorum, 2-4 parts of bletilla striata, 3-5 parts of indigo naturalis, 6-8 parts of mint, 3-4 parts of surfactants, 5-7 parts of soluble starch, 8-10 parts of color fixatives, 30-40 parts of deionized water and 5-7 parts of vegetable oil. The natural waterborne paint ink has the advantages of simple technical process, reasonable raw material ratio, avoidance of chemical component addition, nontoxicity and harmlessness due to adoption of herbaceous raw materials, functions of fragrance increase, oxidation resistance and corrosion resistance due to adoption of edible and medicinal herbaceous plants, functions of foaming, emulsification, dispersing, moistening and the like, synergy of the raw materials for preparation of the environment-friendly paint ink, safety, environment friendliness, naturality, freeness of heavy metals, high cost performance, low cost, fragrance and thick color.

Owner:蚌埠神龙笔业有限公司

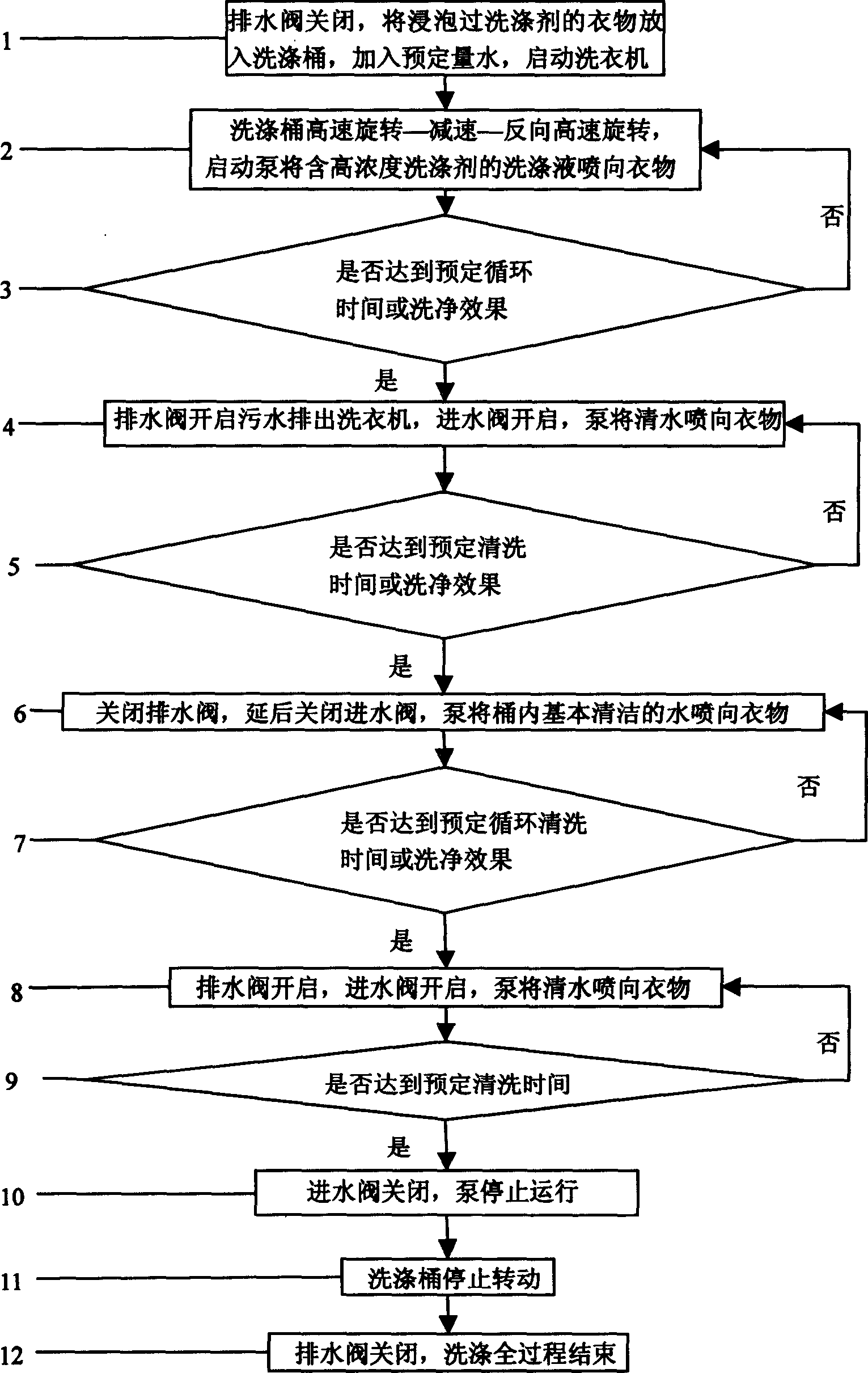

Centrifugal water saving washing method

InactiveCN1651632AImprove decontamination abilityImprove the effect of clean water cleaningControl devices for washing apparatusWashing machine with receptaclesWater savingHigh concentration

The present invention relates to a centrifugal water-saving washing method. It is a new washing method by utilizing washing machine. It is characterized by that it utilizes the centrifugal force produced by high-speed rotation of washing tub to make the washing liquor containing high-concentration detergent or basic clean detergent or clean water pass through the clothes to implement washing or cleaning, and in the washing stage and cleaning stage said washing liquor can be used circularly by using pump, said pump can make the washing liquor passing through the clothes have a certain pressure and speed so as to raise washing efficiency and save water.

Owner:丁伟璜

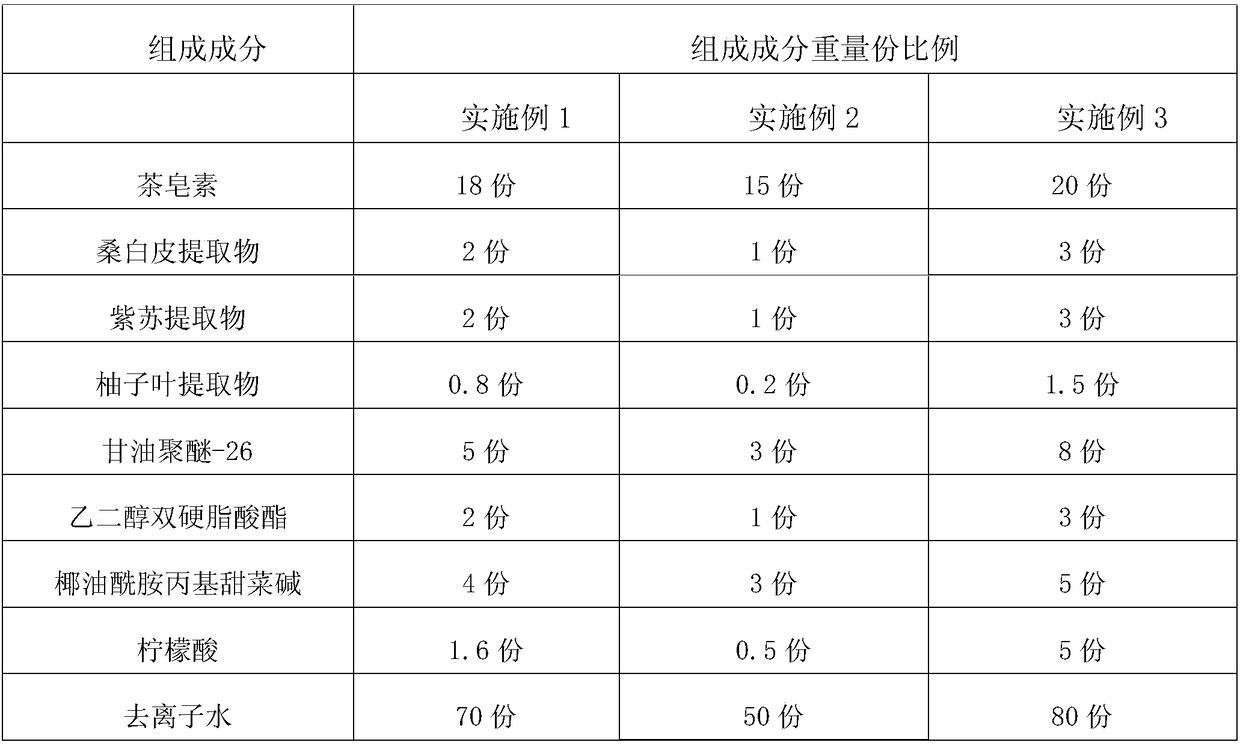

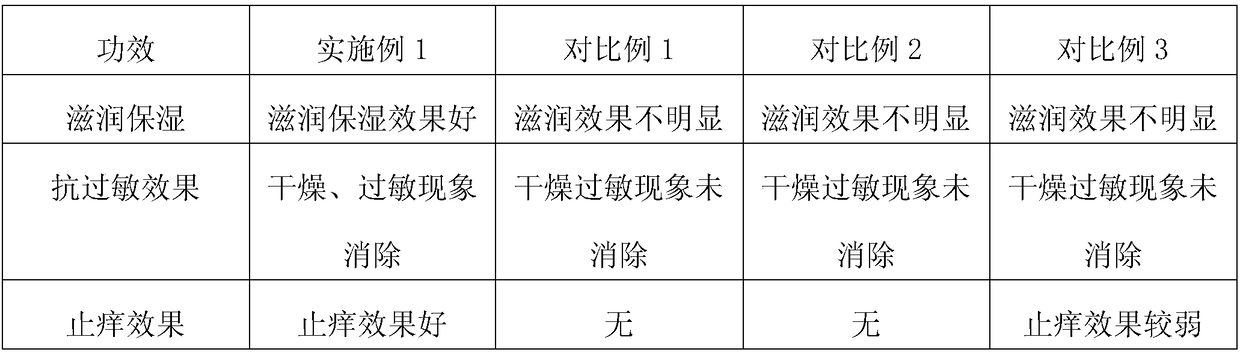

Tea saponin shower gel and preparation method thereof

InactiveCN109125172AAntipruriticWill not polluteCosmetic preparationsToilet preparationsCarcinogenShower gel

The invention belongs to the field of bath products and particularly relates to tea saponin shower gel and a preparation method thereof. The tea saponin shower gel is made from, by weight, 15-20 partsof tea saponin, 1-3 parts of white mulberry root-bark, 1-3 parts of perilla herb extract, 0.2-1.5 parts of pomelo leaf extract, 3-8 parts of glycereth-26, 1-3 parts of ethylene glycol distearate, 3-5parts of cocamidopropyl betaine, 0.5-5 parts of citric acid, and 50-80 parts of deionized water. The tea saponin shower gel is mainly made with the tea saponin that is a natural plant active ingredient, has the effects, such as foaming to remove dirt, resisting bacteria, relieving itching and wetting, has mild performance, is easy to biodegrade and less irritating to skin, is good for human health, is free of carcinogens, such as dioxane, and organics harmful to human, such as benzene and phenol, and is good in safety and environmental friendliness and free of environmental pollution.

Owner:AGRI PROD PROCESSING INST GUANGXI ACADEMY OF AGRI SCI

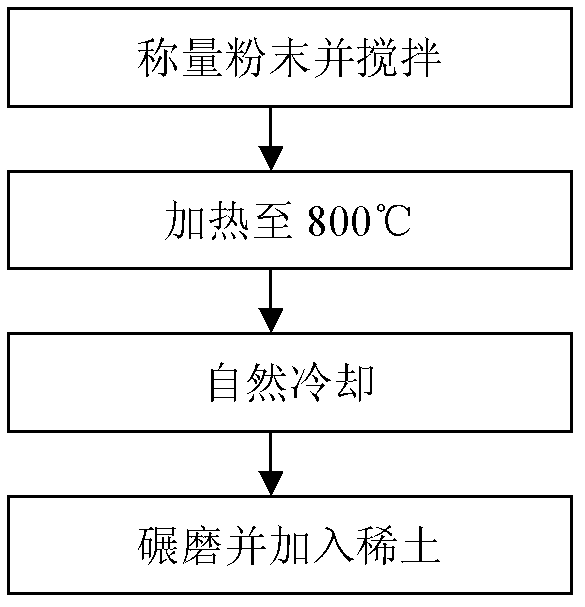

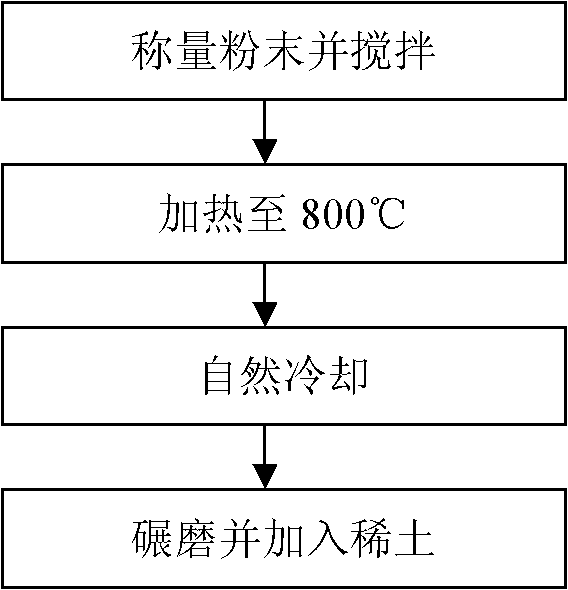

Supercooled IN718 high-temperature alloy purifying agent and preparation method for same

The invention discloses a supercooled IN718 high-temperature alloy purifying agent and a preparation method for the same. The preparation method includes: sufficiently mixing 45-55 parts of CaF2 (calcium fluoride), 8-12 parts of NaCl (sodium chloride), 8-12 parts of KCl (potassium chloride), 18-22 parts of CaO (calcium oxide), 4-6 parts of TiO2 (titanium dioxide), 4-6 parts of MgO (magnesium oxide) and 0.5-1.0 part of AlF3 (aluminum fluoride) to obtain mixed powder; heating the mixed powder to 800 DEG C and then preserving heat for 8 hours; naturally cooling the mixed powder to room temperature after heat preservation; and milling the mixture into powder after crushing the mixture, and adding 0.5-1.0 part of rare earth compound LaCl3 (lanthanum chloride) to obtain the purifying agent. The purifying agent can integrate the functions of overwrite protection, oxidation and volatilization prevention and impurity removal, components of the purifying agent are easy to obtain, the purifying agent is convenient to add, the operating process is simple, and the cost is low.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Multifunctional velvet fabric finishing agent

The invention relates to a multifunctional velvet fabric finishing agent which is prepared from the following raw materials in parts by weight: 3-100 parts of amino acid surfactant, 1-50 parts of emulsifier, 2-80 parts of active lipid amino acid compound, 5-200 parts of protein amino mother solution, 1-50 parts of cocamide diethanolamine and 1-40 parts of amodimethicone. After the amino acid surfactant is compounded with ammonium lauryl sulfate, the multifunctional velvet fabric finishing agent provided by the invention has relatively strong wetting, emulsifying, dispersing, dirt removing and dirt carrying abilities as well as good detergent washing durability, and realizes moderate oil removal without influencing the brightness; moreover, the multifunctional velvet fabric finishing agent improves the smooth and fluffy handfeel of fabric, and has high stability for hard water to realize good gloss and elasticity of the fabric; with good biodegradability, the multifunctional velvet fabric finishing agent is easy to process biologically; and the fulling and softening can be integrated, thus the fulling and softening processes are simplified, the labor intensity and the processing cost are reduced, and the production efficiency is improved.

Owner:INNER MONGOLIA ORDOS RESOURCE

Formula for paper making assistant

The paper making assistant consists of sodium hydrogen sulfate 6-7.5 wt%, alkyl sodium sulfonate 6.5-8 wt%, polyoxyethylene alkyl ether 12-15 wt%, penetrant mp 0.1-0.5 wt%, and water 70-75 wt%. The sodium hydrogen sulfate is prepared with anhydrous sodium sulfate, concentrated sulfuric acid and water in 20 deg.c in the weight ratio of 12 % to 24 % to 60 % and through mixing. The assistant can result in high production efficiency and low environmental pollution.

Owner:赵炳晨

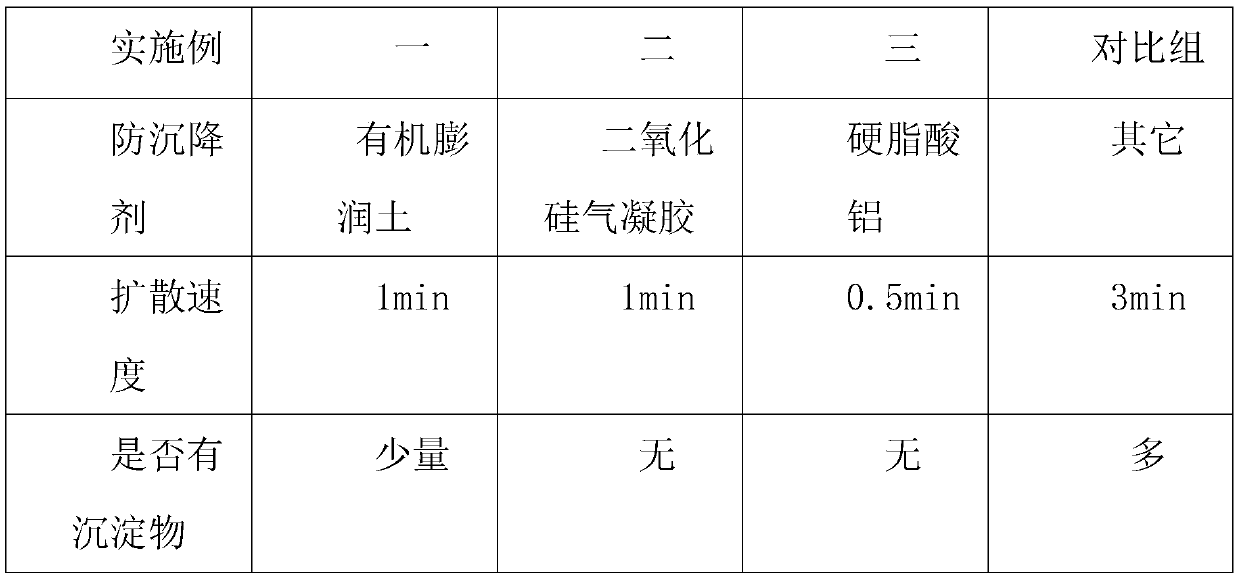

Anti-precipitation ink based on printer inkjet stability

The invention relates to the field of printer ink, in particular to anti-precipitation ink based on printer inkjet stability. The anti-precipitation ink is prepared from the components with parts as ameasuring unit: 30-50 parts of carbon black powder, 20-50 parts of deionized water, 1-2 parts of an anti-precipitation agent, 5-10 parts of a moisturizing agent, 1-3 parts of a PH conditioner, 1-4 parts of a surface active agent, 1-6 parts of a dispersant, 0.5-1 part of a lubricant, 1-5 parts of a thickener, 0.02-0.4 part of a preservative, 0.1-0.3 part of an active dye agent, 0.2-0.5 part of ananti-rust agent, 0.2-0.8 part of a defoamer and 1-3 parts of balsam. A method comprises the following step: S1, screening is conducted, specifically, the carbon black powder in the raw materials is placed into a screen net to be screened. The anti-precipitation ink has the beneficial effects that through the arranged anti-precipitation agent, the anti-precipitation agent has ultra-high pigment diffusivity, wetting performance and lubricity on the ink, thus a pigment in the ink can be durably and evenly distributed under a static or dynamic environment without being precipitated, the multiple common phenomena such as ink gathering, ink dissolving or not-bright color can be easily avoided, the printer inkjet quality is improved, and the service life of a spray head is prolonged.

Owner:珠海市彩诺电子科技有限公司

Electroplating degreasing agent for secondary cold rolled material

The invention relates to a metal degreasing agent, in particular to an electroplating degreasing agent for a secondary cold rolled material. The electroplating degreasing agent for the secondary cold rolled material comprises the following chemical components in percentage by weight: 20 to 25 percent of potassium hydroxide, 1 to 4 percent of potassium gluconate, 5 to 13 percent of organic polymer complexing agent, 3 to 5 percent of surfactant, and the balance of water. The organic polymer complexing agent is 9EO+10PO and the chemical name thereof is polyoxypropylene polyoxyethylene block copolymer. The surfactant is HAS and the chemical name thereof is hydroxylamine sulfate. The electroplating degreasing agent for the secondary cold rolled material has very strong moistening and stripping functions on dirt, and the stripped greasy dirt floats on the liquid surface, is easy to discharge and rinse; besides, the electroplating degreasing agent avoids the white spot problems and the tinning defects on a tin plate and reduces the roll marks defects.

Owner:BAOSHAN IRON & STEEL CO LTD

Carton Waterproof Coating

ActiveCN102704330BSimple recipeSimple processCoatingsPaper forming aids additionParaffin waxEmulsion

Owner:ANHUI JINDUN PAINT

Phenol-degrading bacterium strain capable of producing biological surfactant and application thereof

ActiveCN109837227AImprove degradation efficiencyStrong emulsifying abilityBacteriaWater contaminantsAlkanePhenol

The present invention relates to a phenol-degrading bacterium strain capable of producing a biological surfactant and an application thereof. A technical solution is as follows: the provided bacteriumstrain is pseudomonas plecoglossicida BPH-3 which is preserved by the China Center for Type Culture Collection, a preservation number is: CCTCC NO:M 2019144, and a preservation date is March 14, 2019. A GenBank accession number of 16S rDNA of the pseudomonas plecoglossicida BPH-3 is MK575471, the pseudomonas plecoglossicida BPH-3 is a Gram-negative bacterium strain, and colony is milky white andround, smooth in surface and neat in edges; and after Gram staining, the pseudomonas plecoglossicida BPH-3 is negative under a microscope and presents a short-rod shape. During fermentation degradation, the phenol-degrading bacterium strain forms a glycolipid biological surfactant which can promote solubilization, emulsification, wetting and osmosis of long-chain alkanes and can effectively degrade phenol in coking wastewater and petrochemical wastewater.

Owner:WUHAN UNIV OF SCI & TECH

Concrete pumping agent

The invention belongs to the technical field of concrete admixture and particularly relates to a concrete pumping agent. The concrete pumping agent is prepared from raw materials in parts by weight as follows: 30-60 parts of a polycarboxylate superplasticizer, 15-31 parts of alkyl glycoside, 10-22 parts of tea saponin, 5-18 parts of a water liquid from a sugar factory, 6-16 parts of sodium lignin sulfonate, 4-16 parts of borax, 1-6 parts of polytetrafluoroethylene and 40-60 parts of water. The concrete pumping agent has good flowability, the durability of concrete is remarkably improved, and the problem of faster loss of concrete slump is well solved.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

Environment-friendly and efficient decontamination automobile windshield washer fluid

InactiveCN109762674AKeep it bright and transparentReduced brightness and transparencyOrganic detergent compounding agentsNon-ionic surface-active compoundsShellacWindshield washer fluid

The invention discloses environment-friendly and efficient decontamination automobile windshield washer fluid. The environment-friendly and efficient decontamination automobile windshield washer fluidis prepared from the following raw materials: an antifreezing agent, modified sodium lignin sulfonate, a tea saponin surfactant, an antistatic agent and water, wherein the tea saponin surfactant is at least one of a tea saponin octanoate surfactant and a tea saponin succinate surfactant. Compared with the prior art, the environment-friendly efficient decontamination automobile windshield washer fluid has the advantages of being extremely strong in wetting and cleaning performance, good in cleaning effect and convenient and rapid to use, water stains, shellac and dirt on an automobile windshield can be thoroughly cleared, the windshield is kept bright and transparent, meanwhile, the water scraping resistance of wiper blades can be reduced, the functions of preventing mildew and recoveringelasticity are achieved on the wiper blades, and the windshield washer fluid can prevent corrosion and is suitable for being used in summer in the north and all year round in the south.

Owner:徐茶香

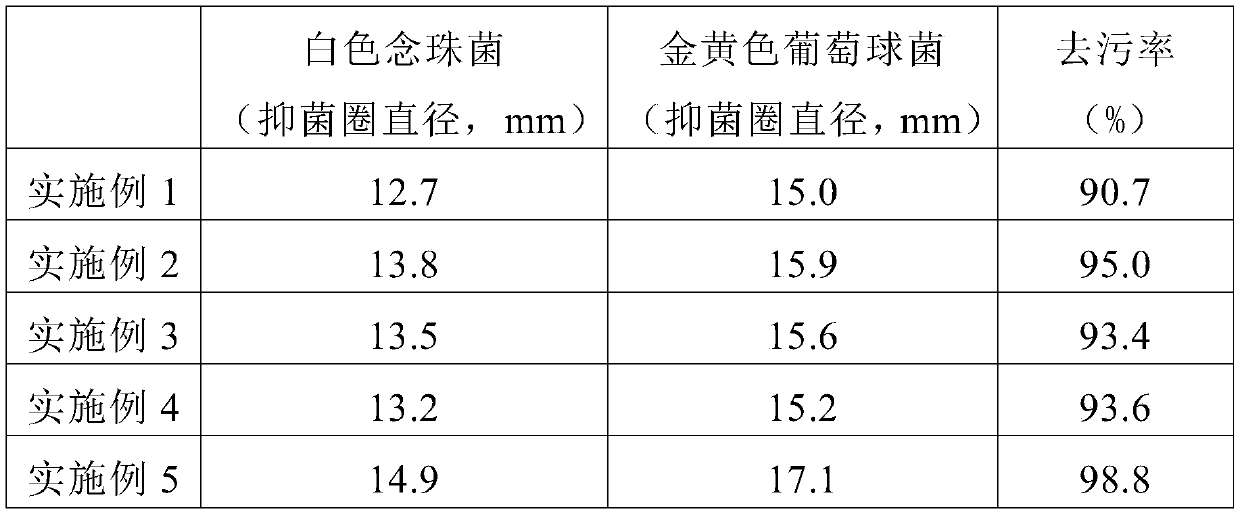

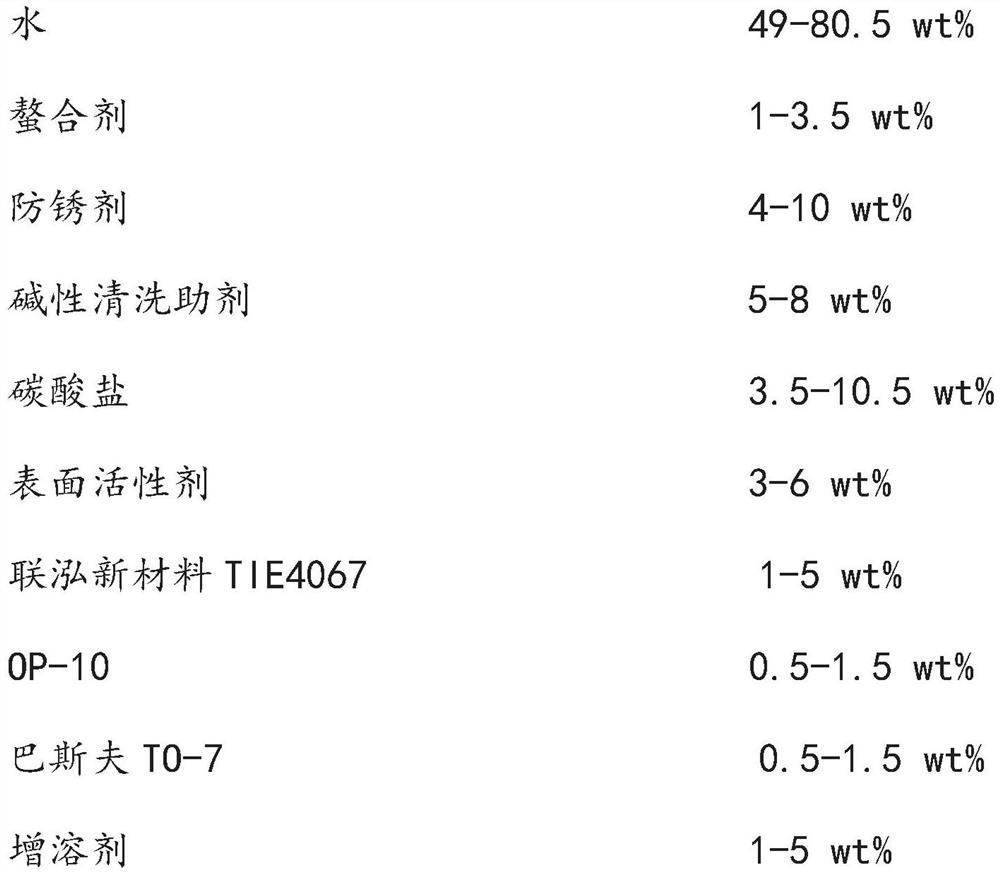

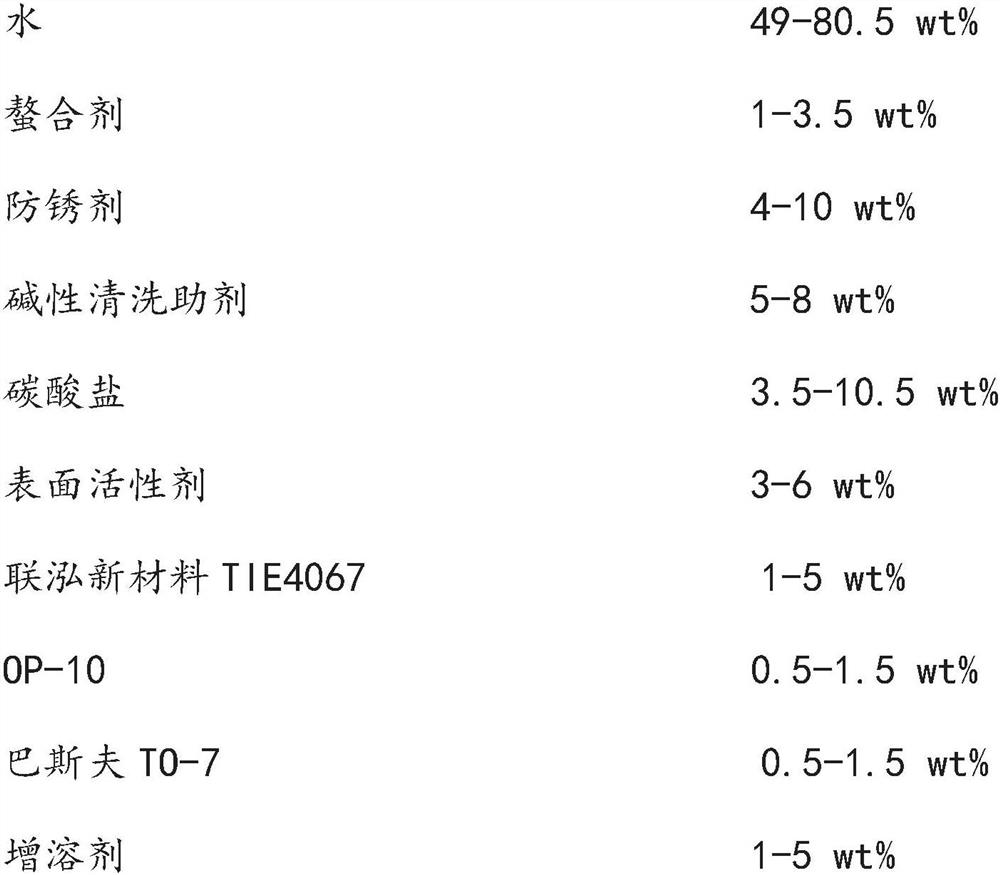

Low-temperature ultrasonic washing agent for black metal and preparation method of low-temperature ultrasonic washing agent

The invention discloses a low-temperature ultrasonic washing agent for black metal and a preparation method of the low-temperature ultrasonic washing agent, and belongs to the technical field of ultrasonic washing agents. The preparation method comprises the following steps: S1, adding part of water, a chelating agent and an antirust agent into a clean container, and carrying out stirring at a low speed until the liquid is dissolved; S2, adding an alkaline washing aid into the container, and continuously stirring the liquid in the container; and S3, adding the balance of water, carbonate, a surfactant, Lianhong novel material TIE406, OP-10, BASF-TO-7 and a solubilizer into the container, and stirring the solution in the container at a low speed until the solution is transparent light yellow uniform liquid, so that the finished product is formed. According to the washing agent disclosed by the invention, the nonionic surfactant, the antirust agent, the chelating agent and the alkaline washing aid are taken as main bodies, a mixture consisting of inorganic salt, the solubilizer and the surfactant is added, and thus the washing agent is safe to use, friendly to the environment and human bodies, good in stability, free of rust and color change after washing, and capable of being used in a medium-low temperature range.

Owner:富兰克润滑科技(太仓)有限公司

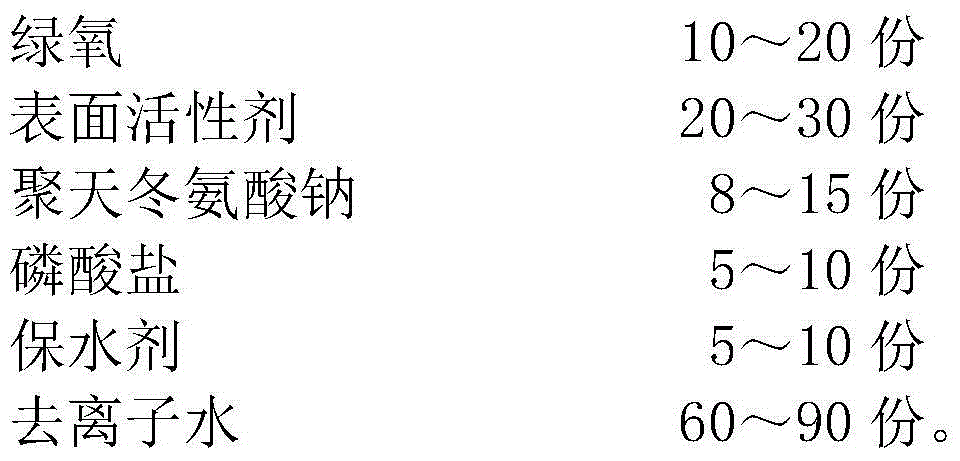

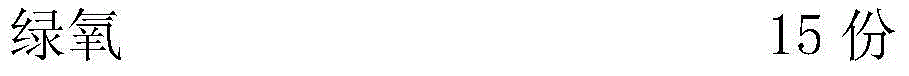

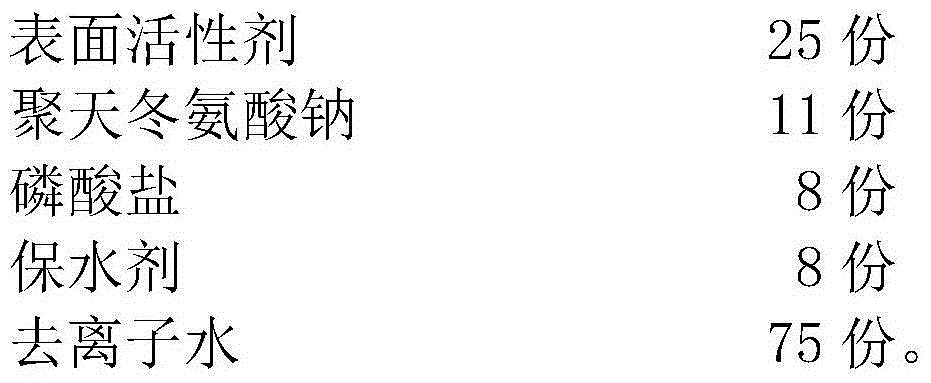

Papermaking cooking assistant

InactiveCN104790243AImprove solubilityEnhanced complexationCellulose material pulpingPhosphatePapermaking

The invention relates to the technical field of papermaking, and particularly relates to a papermaking cooking assistant which is prepared from the following raw materials in parts by weight: 10-20 parts of green oxygen, 12-24 parts of sulfated castor oil, 20-30 parts of surfactant, 5-10 parts of phosphate, 5-10 parts of water retention agent and 60-90 parts of deionized water. The papermaking cooking assistant greatly enhances the cooking effect, enhances the raw material permeability, improves the cooking uniformity, quickly adsorbs alkali liquor, increases the transmission speed of the reaction product in the raw materials, accelerates cooking, obviously shortens the cooking time, and greatly improves the pulp quality and paper strength.

Owner:陈朝民

A kind of coconut pancake and preparation method thereof

The invention discloses a coconut pancake and a preparation method thereof. The coconut pancake comprises the following components in parts by weight: 25-35 parts of fresh coconut juice, 5-8 parts of white granulated sugar, 0.5-2 parts of salt, 50-60 parts of low gluten wheat flour, 30-40 parts of rice flour, 25-30 parts of glutinous rice flour, 20-25 parts of eggs, 3-6 parts of granulesten, 15-20 parts of whole milk powder, 10-12 parts of xylitol, 1-3 parts of vegetable oil and the balance of water. The coconut pancake provided by the invention is thin, crisp, abundant in nutrition, simple and convenient in preparation method, and easy to large-scale production.

Owner:HAINAN NANGUO FOODSTUFF IND

A kind of environment-friendly washable watercolor ink and preparation method thereof

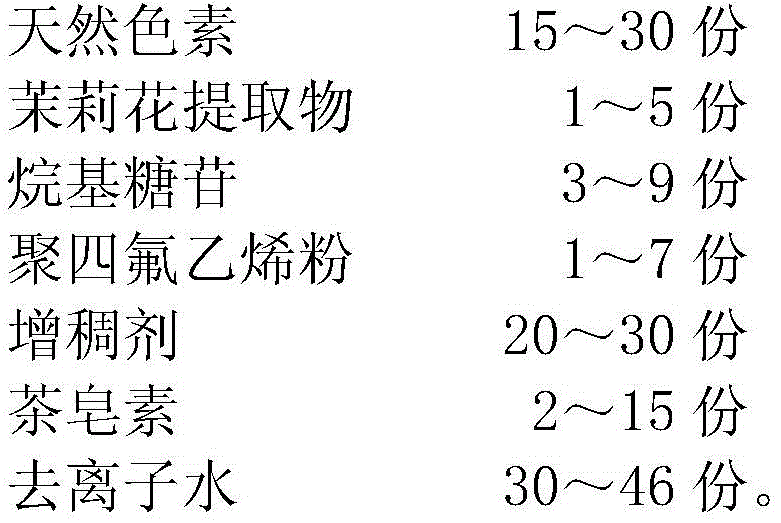

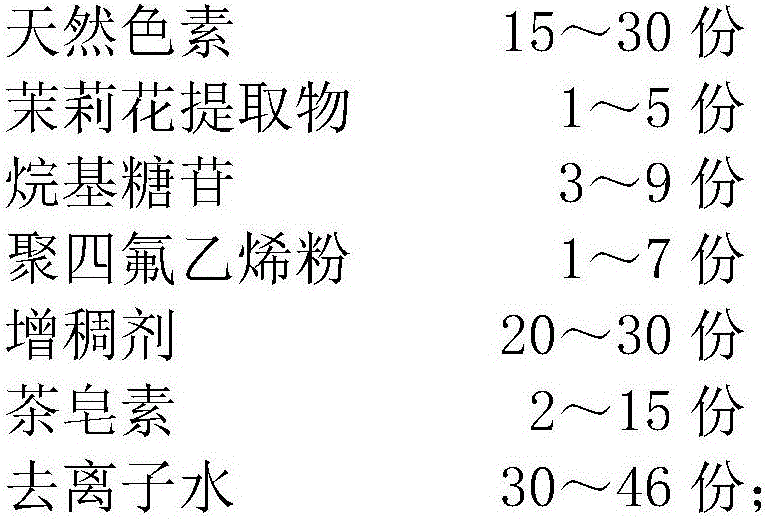

ActiveCN104559476BAnti-oxidant and anti-corrosion effectStrong emulsificationInksEnvironmental resistancePrice ratio

The invention relates to the technical field of ink, and particularly relates to environmental-friendly easily-cleaning watercolor ink. The environmental-friendly easily-cleaning watercolor ink is prepared from the following raw materials in parts by weight: 10-20 parts of natural pigments, 1-5 parts of jasmine extracts, 3-9 parts of alkyl glycoside, 1-7 parts of polytetrafluoroethylene powder, 20-30 parts of thickening agents, 7-15 parts of tea saponin and 30-46 parts of deionized water. The invention also provides a preparation method of the environmental-friendly easily-cleaning watercolor ink. A main process comprises the following steps of: increasing temperature, mixing, and uniformly stirring. The environmental-friendly easily-cleaning watercolor ink prepared through the mutual synergism of the raw materials is safe, green, natural, free of heavy metal components, high in performance price ratio, simple in preparation process, low in cost, fragrant in smell and strong in color.

Owner:肇庆斯塔文化用品有限公司

Machine wash tableware cleaning agent

InactiveCN108034520AImprove washabilityReduce foam volumeInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPolyethylene glycolCleansing Agents

The invention discloses a machine wash tableware cleaning agent which comprises octyl-phenol polyoxyethylene, sodium alcohol ether sulphate, sorbitan fatty acid ester, iodopropynyl butylcarbamate, diethanol amine, sodium carboxymethylcellulose, bis(hydroxymethyl)imidazolidinyl urea, a fluorosilicone antifoaming agent, polyethylene glycol, sodium carbonate and water. The cleaning agent disclosed bythe invention is outstanding in washing effect, still has excellent effects of wetting, emulsifying and saponifying oil while ensuring small foam output, has high detergency, and has obvious decontamination effects on residual oil, protein dirt and tea residues on the tableware. Moreover, the product does not hurt the hands, is convenient to flush, has the characteristics of being water-saving, electricity-saving, high in washing effect and the like, and has high economic benefits when being applied to the large-scale machine wash industry.

Owner:广州馨香日用化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com