Aluminium magnesium alloy and its composite material continuously concreting and forming integrative device

A composite material and magnesium alloy technology is applied in the field of metal material processing devices, which can solve the problems of shortening the process flow, and no device integrating solidification and forming of aluminum-magnesium alloys and their composite materials has been found, so as to improve the strengthening effect and improve the The effect of interface compatibility and material saving use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

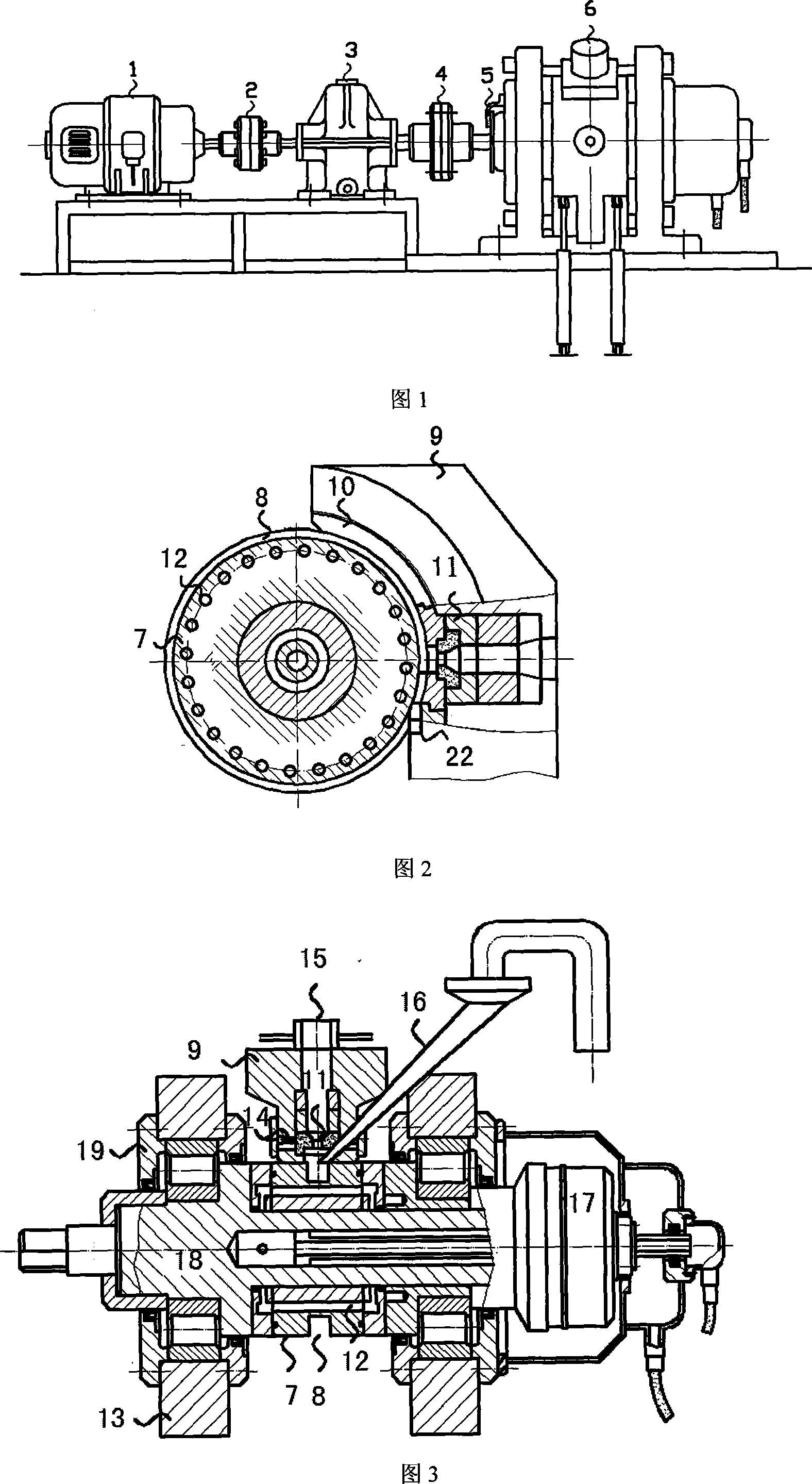

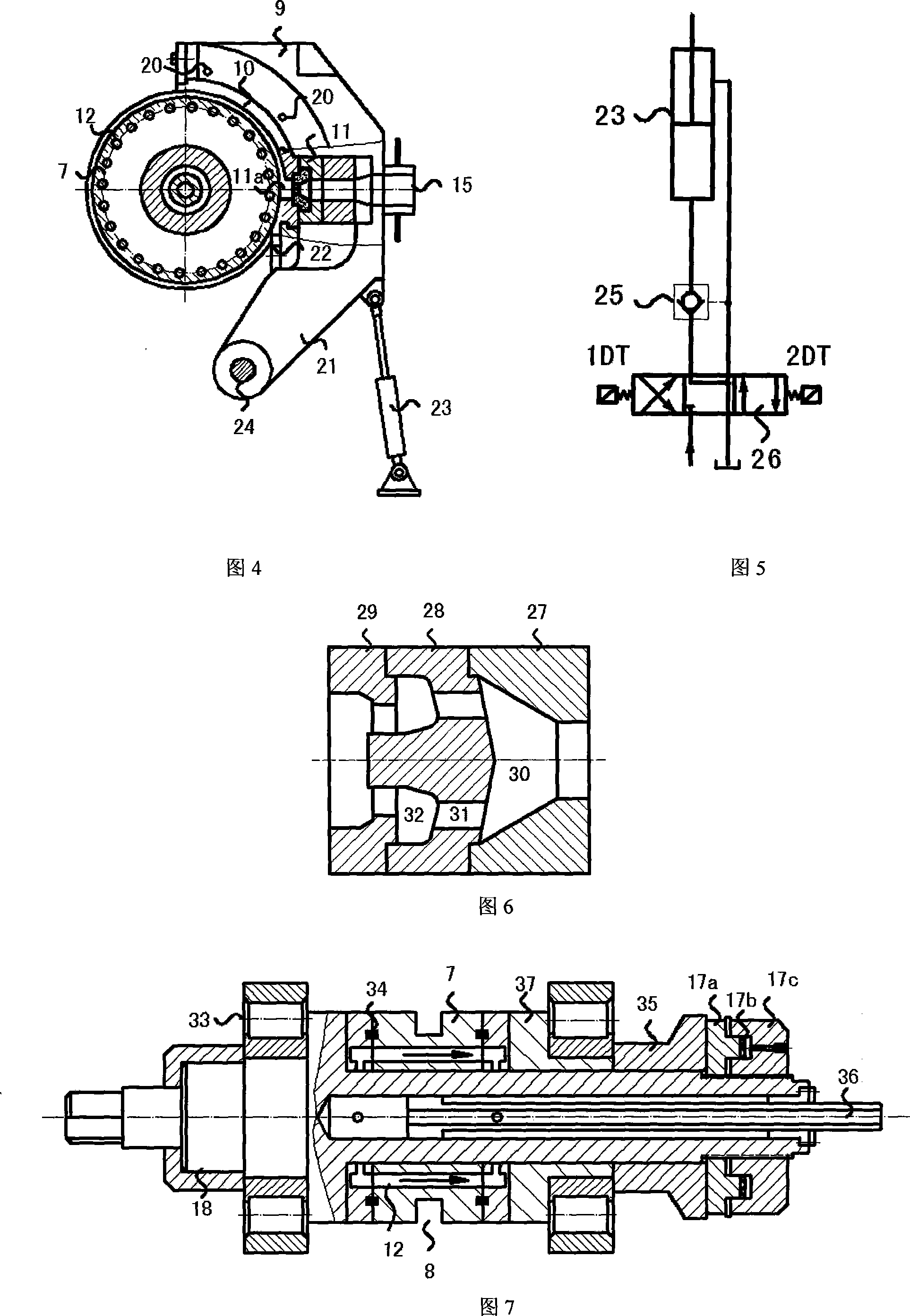

[0030] As shown in Figure 1, the device of the present invention is a DC motor selected from the motor 1, which is connected to one end of the 3 shafts of the reducer through the elastic coupling I2, and the other end shaft of the reducer 3 is connected to the elastic coupling II4, and the elastic coupling II4 It is connected with the hollow shaft 18 of the main engine, and a speed and torque sensor 5 is arranged at the head of the main engine to monitor force and speed parameters.

[0031] As shown in Fig. 2, Fig. 3, Fig. 4, Fig. 5, Fig. 6 and Fig. 7, the main engine 6 mainly has a water-cooled wheel train, which consists of a hollow shaft 18 and ball bearings 33 assembled on the left and right sides of the hollow shaft 18. The sealing baffle 19 on both sides thereof is fixed on the frame 13 through the vertical plate on the bottom plate of the frame 13, the ball bearing 33 is fixed and sealed by the sealing baffle 19, and the middle position of the hollow shaft 18 is assemble...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com