Method for melt-spinning, drawing, and winding up a multifilament, and apparatus for carrying out said method

A technology of melt spinning and multifilament yarn, applied in the field of drawn yarn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

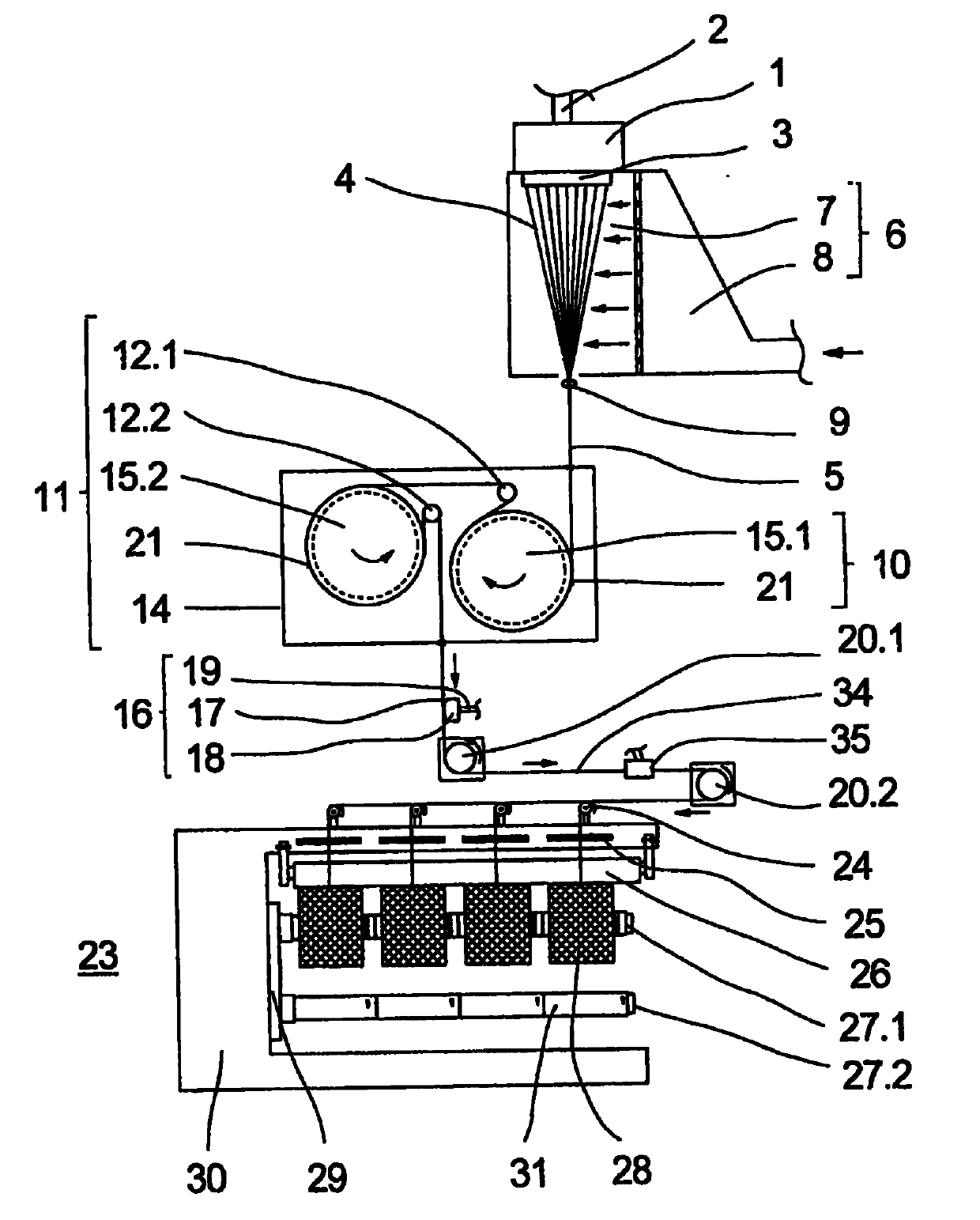

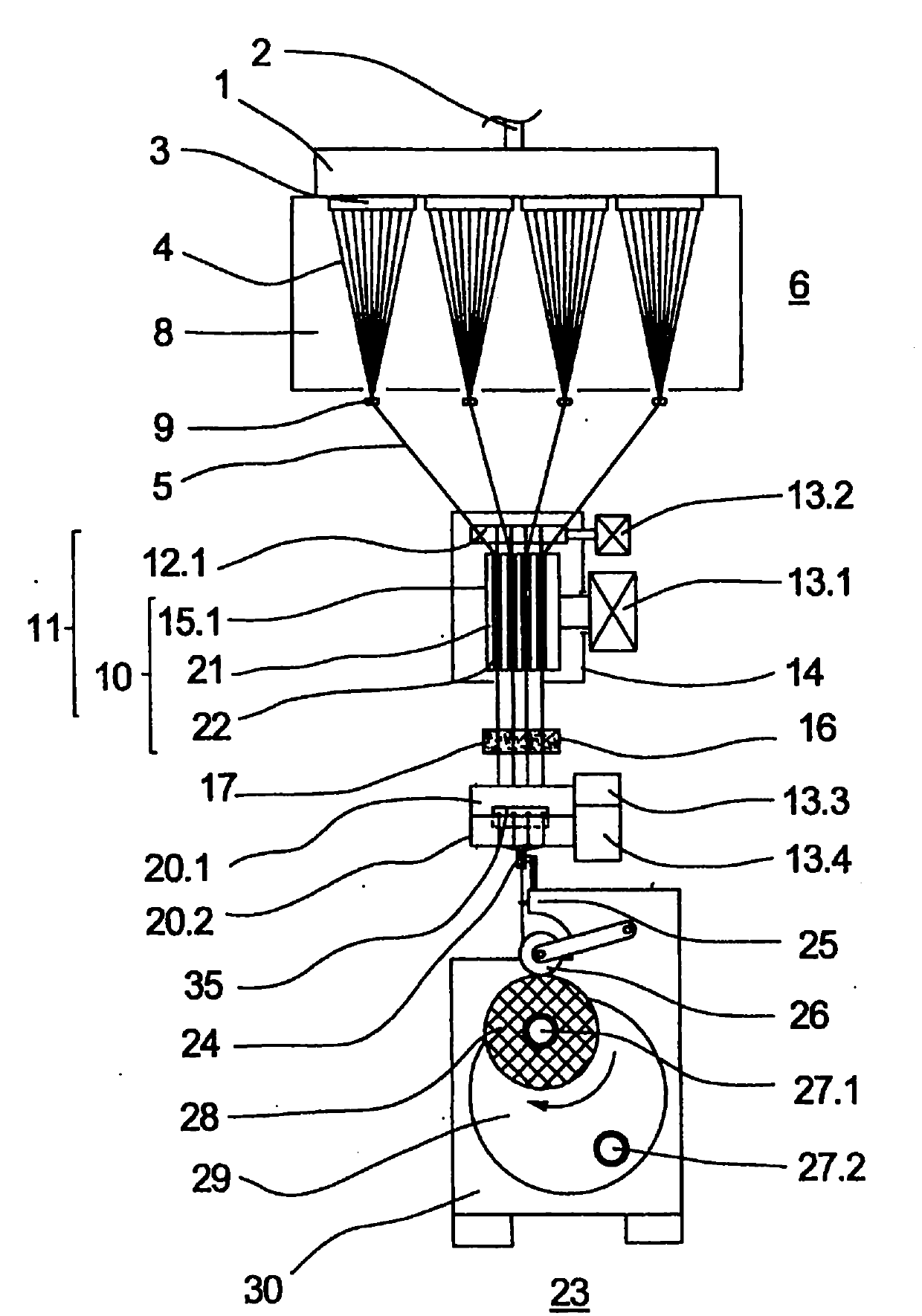

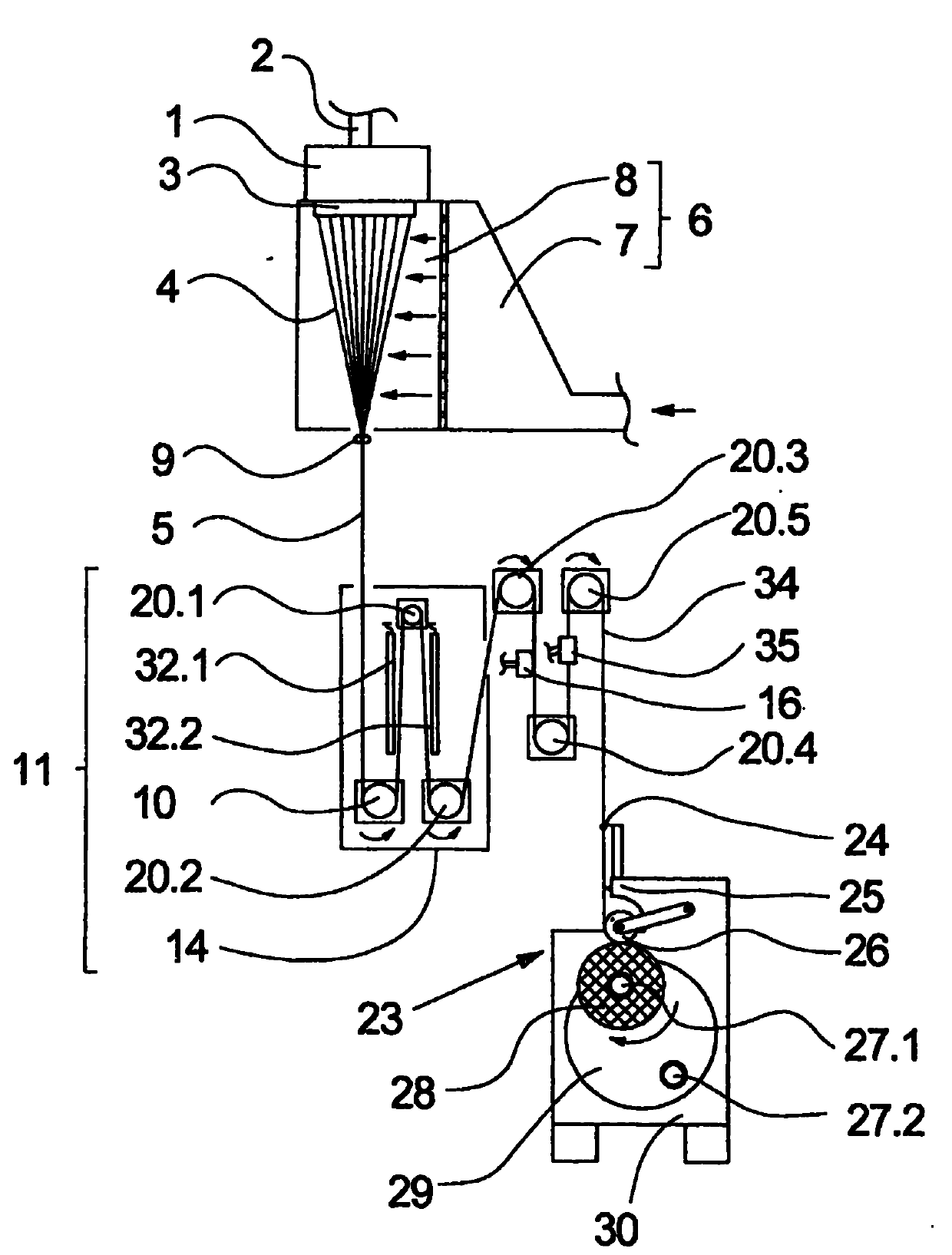

[0034] in the attached figure 1 and 2 A first embodiment of an apparatus according to the invention for carrying out the method for producing fully drawn yarns according to the invention is shown in several views. in the attached figure 1 The embodiment is shown in side view and in the appended figure 2 Shown in front view. The following description applies to both figures as long as no explicit reference is made to one of the figures.

[0035] For melt spinning a multifilament yarn, a heatable spinneret 1 is provided, which has spinning nozzles 3 on its bottom side, which have a number of spinneret holes, and the spinneret in It has a melt inlet 2 on its upper side. The melt inlet 2 is coupled to a melt source (not shown here), for example an extruder. Further melt-guiding and melt-conveying components can be arranged inside the spinneret 1 , which will not be described in detail here.

[0036] The spinneret has a plurality of spinning nozzles 3 on its underside in or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com