Centrifugal water saving washing method

A washing method and centrifugal washing technology, which are applied to washing devices, washing machines with containers, and washing machine control devices, etc., which can solve the problems of increasing clothing damage and fiber shedding, increasing the difficulty of inner tubs, and affecting the decontamination effect of detergents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

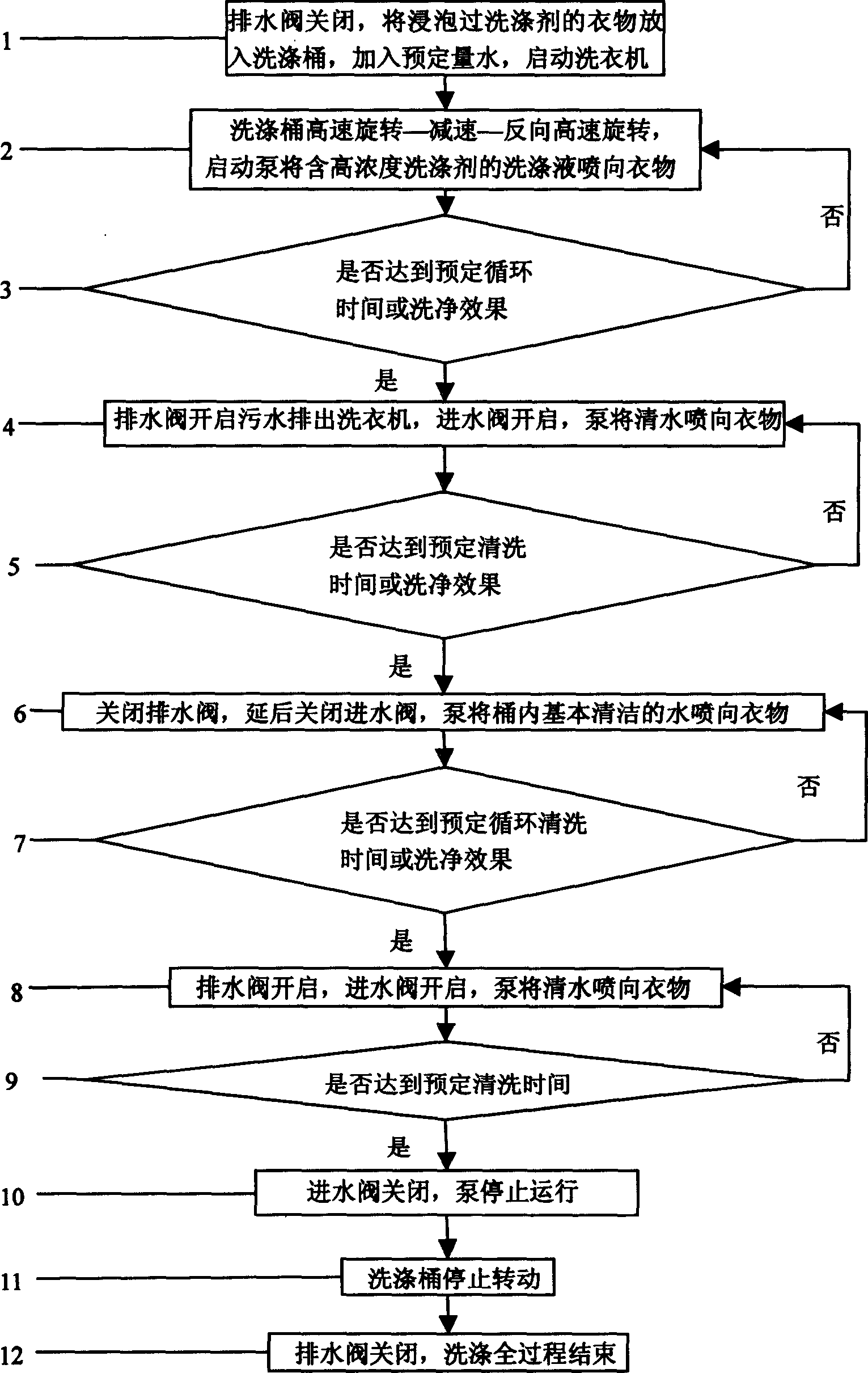

[0023] The washing of the centrifugal water-saving washing method is described below in conjunction with the figure--the whole process of cleaning. Because the techniques and devices required for this washing method are already disclosed or commercialized, they are not specifically described or marked in this specification and the drawings, and only the implementation process of this method is described:

[0024] Pre-soak the clothes in the washing liquid containing detergent for a certain period of time, and put them into the washing bucket. At this time, the drain valve is closed. Since the amount of water for soaking clothes is generally small, you can inject a predetermined amount of water into the washing machine and start the washing machine. Washing machine (1); the amount of water can be obtained by experiment or experience according to the quality and amount of the clothes, and an automatic detection device can also be adopted. The washing bucket starts to rotate at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com