Gas hydrate accelerant and preparation method thereof

A technology of gas hydrates and accelerators, which is applied in the direction of gas fuels, chemical instruments and methods, and other chemical processes, can solve the problems that hinder the greening of hydrate technology, the limited promotion effect of hydrates, and the low reuse rate, and achieve Shorten the generation time, promote the effect, and have obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

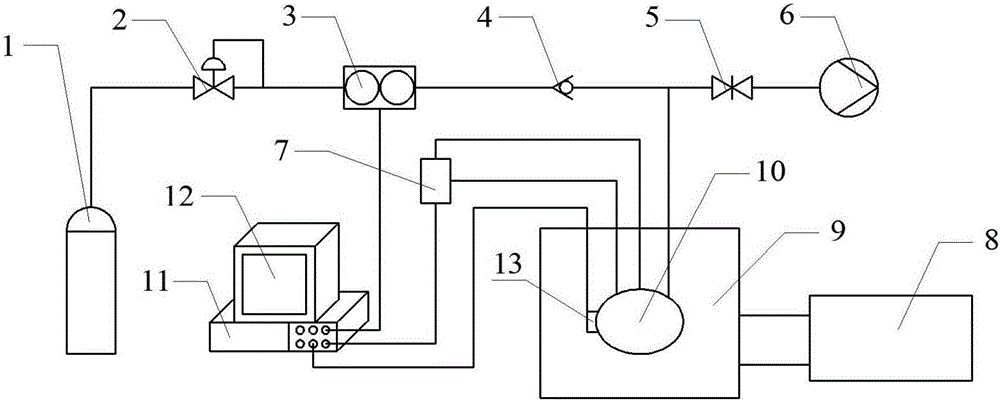

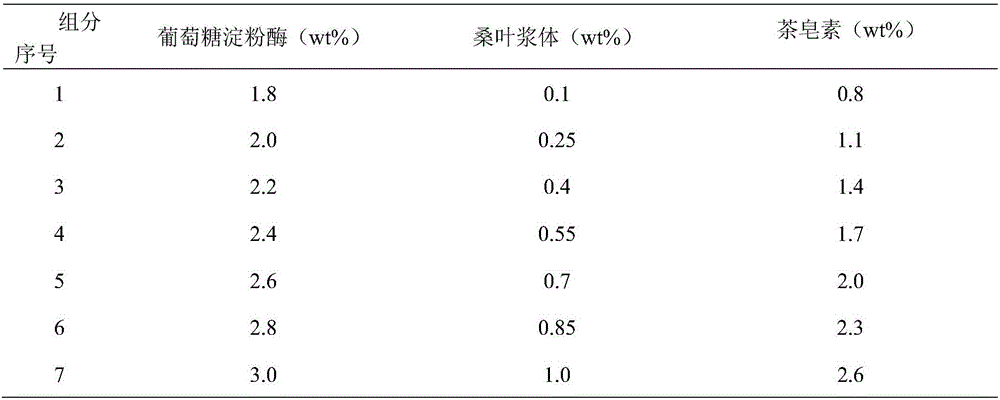

[0030] 1) According to the preparation steps of the above-mentioned hydrate accelerator, hydrate accelerators with different concentrations were prepared according to the accelerator components shown in Table 1.

[0031] 2) Vacuumize the reactor 10 and the piping system with a vacuum pump for 40-50 minutes.

[0032] 3) In order to get rid of the air in the reactor 10 and the pipeline system as much as possible, they were replaced twice with the test gas, and then vacuumized again.

[0033] 4) The prepared hydrate accelerator is injected into the reactor 10 as an aqueous solution with a concentration of 400-800 ppm, and stirred for 3-5 minutes.

[0034] 5) Open the one-way valve (4), fill the reactor with high-pressure experimental gas, and maintain the pressure of the reaction system at the required pressure of 0-30 MPa through the pressure regulating valve (2).

[0035] 6) Set the experimental temperature and start the temperature control system of the experimental device. ...

Embodiment 1

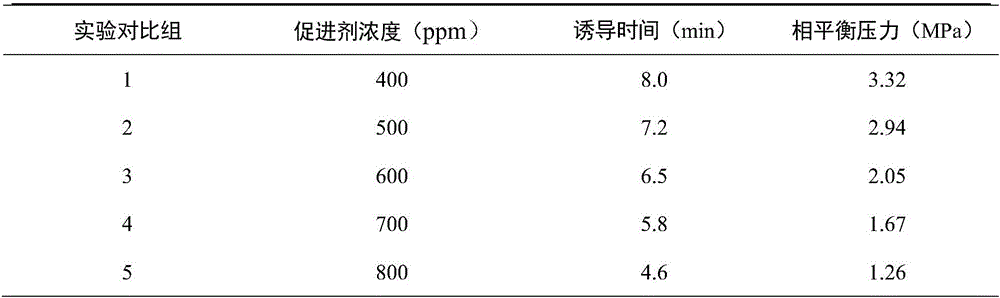

[0043]The composition of the high-efficiency degradable hydrate accelerator selected is as follows: the mass concentration of glucoamylase is 1.8%, the mass concentration of tea saponin is 0.8%, and the mass concentration of mulberry leaf powder slurry is 0.1%. Add deionized water and stir at 50°C for 60 minutes to make a hydrate accelerator. The accelerator is diluted to 400-800ppm aqueous solution and injected into the reactor, and the experiment is carried out with methane gas at a temperature of 7°C, and the experiment procedure is the same as above. The experimental results are shown in Table 2. Under the conditions of the above-mentioned Example 1, it is obtained through experiments that the induction time of hydrate formation is 4.6-8.0 min, and the higher the mass concentration of the accelerator, the shorter the induction time.

[0044] Table 2 Hydrate promoter concentration and experimental results

[0045]

Embodiment 2

[0047] The selected high-efficiency degradable hydrate accelerator components are as follows: the mass concentration of glucoamylase is 3%, the mass concentration of tea saponin is 2.6%, and the mass concentration of mulberry leaf powder slurry is 1%. Add deionized water and stir at 50°C for 60 minutes to make a hydrate accelerator. The accelerator is diluted to 400-800ppm aqueous solution and injected into the reactor, and the experiment is carried out with methane gas at a temperature of 7°C, and the experiment procedure is the same as above. The experimental results are shown in Table 3. Under the conditions of Example 2 above, the induction time of hydrate formation is 1.3-4.3 minutes, and the higher the mass concentration of the accelerator, the shorter the induction time.

[0048] Table 3 Hydrate promoter concentration and experimental results

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com