Environmental-protection composite dust suppressant, and preparation method thereof

A composite dust suppressant technology, applied in chemical instruments and methods, and other chemical processes, can solve problems such as being easily washed away by rain, lack of coupling mechanism between surfactants and polymer materials, and high preparation costs, achieving Good biodegradability, high production and application value, effect of reducing heavy metal content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

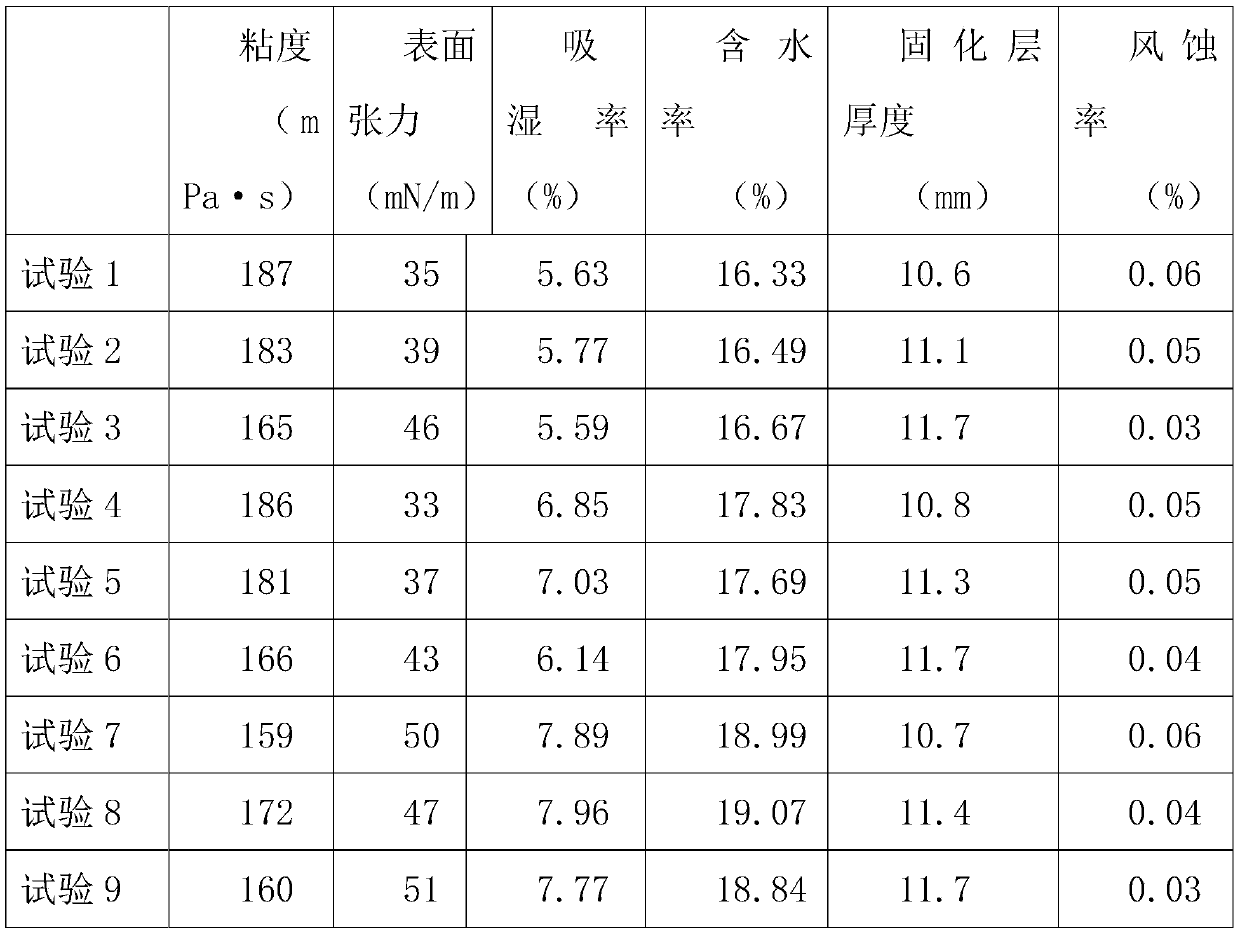

Examples

Embodiment 1

[0025] An environmentally friendly composite dust suppressant, comprising the following components by weight: 40 parts of modified starch, 5 parts of wetting agent, 0.5 part of adsorbent and 0.1 part of crosslinking agent, the wetting agent is sodium dodecylsulfonate, The adsorbent is chitin, the crosslinking agent is triallyl cyanurate, and the modified starch is modified by dual-frequency ultrasonic waves;

[0026] Its preparation method comprises the following steps:

[0027] S1: Preparation of modified starch: take deionized water, disperse starch evenly in it, prepare starch milk, the mass fraction of starch milk is 32%, and place it under the condition of double-frequency ultrasonic wave, take it out and put it in Dried in a drying oven until the water content is 7%, and then crushed to obtain modified starch, wherein the dual-frequency ultrasonic conditions include working power, single working time, intermittent time, total working time, working frequency and working t...

Embodiment 2

[0031] An environmentally friendly composite dust suppressant, comprising the following components by weight: 60 parts of modified starch, 15 parts of wetting agent, 5 parts of adsorbent and 3 parts of crosslinking agent, the wetting agent is sodium polyacrylate and fluorosurfactant , the adsorbent is chitin and chitosan, the crosslinking agent is triallyl cyanurate, and the modified starch is modified by dual-frequency ultrasonic waves;

[0032] Its preparation method comprises the following steps:

[0033] S1: Preparation of modified starch: take deionized water, disperse starch evenly in it, prepare starch milk, the mass fraction of starch milk is 38%, and place it under the condition of double-frequency ultrasonic wave, take it out and put it in a dry place after the treatment is completed Oven drying, until the water content is 10%, and then pulverized to obtain modified starch, wherein, the dual-frequency ultrasonic conditions include working power, single working time, ...

Embodiment 3

[0037] An environmentally friendly composite dust suppressant, comprising the following components by weight: 50 parts of modified starch, 10 parts of wetting agent, 2.5 parts of adsorbent and 1.5 parts of crosslinking agent, the wetting agent is sodium dodecylbenzenesulfonate , the adsorbent is chitosan, the crosslinking agent is triallyl cyanurate, and the modified starch is modified by dual-frequency ultrasonic waves;

[0038] Its preparation method comprises the following steps:

[0039] S1: Preparation of modified starch: take deionized water, disperse starch evenly in it, prepare starch milk, the mass fraction of starch milk is 35%, and place it under the condition of double-frequency ultrasonic wave, take it out and put it in the dry place after the treatment is completed Oven-dried to 8% water content, then crushed to obtain modified starch, wherein, the dual-frequency ultrasonic conditions include working power, single working time, intermittent time, total working ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com