Papermaking cooking assistant

A cooking aid and water-retaining agent technology, applied in the field of papermaking, can solve the problems of long lignin decomposition and dissolution time, affecting pulp quality and yield, poor solubility, etc., achieve good scale inhibition effect, inhibit peeling reaction, The effect of improving whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

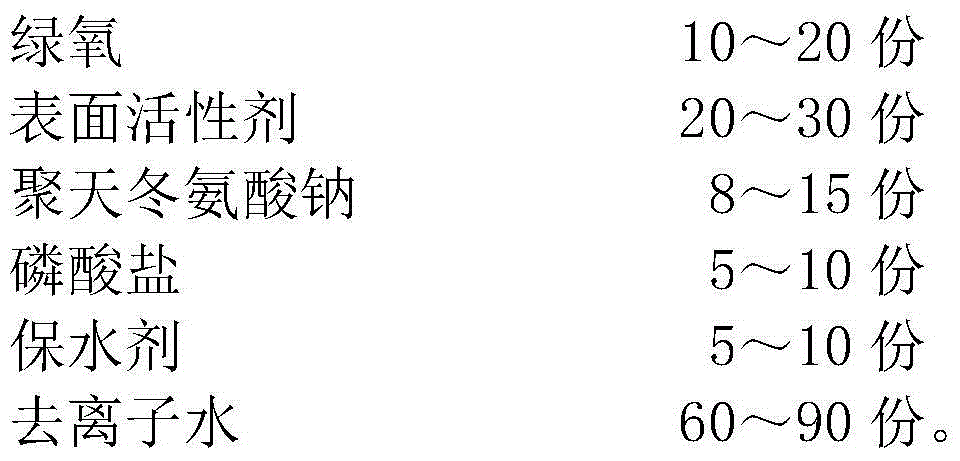

[0021] Weigh the following raw materials in parts by weight:

[0022]

[0023] The surfactant is a mixture of alkyl glucoside, sodium dodecylbenzenesulfonate and tea saponin with a mass ratio of 5:3:1.

[0024] The water retaining agent is a mixture of methylcellulose, hydroxypropylmethylcellulose and hydroxyethylmethylcellulose in a mass ratio of 6:4:1.

[0025] The preparation method of papermaking cooking aid is as follows:

[0026] Put the deionized water into the stirring tank, raise the temperature to 40°C, add the water retaining agent while stirring, stir until it is completely dissolved, then add green oxygen, surfactant, sodium polyaspartate and potassium phosphate in sequence, and dissolve completely Can.

Embodiment 2

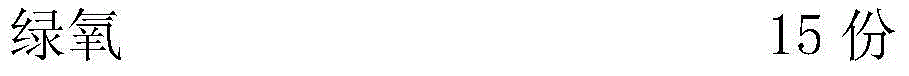

[0028] Weigh the following raw materials in parts by weight:

[0029]

[0030]

[0031] The surfactant is a mixture of alkyl glucoside, sodium dodecylbenzenesulfonate and tea saponin with a mass ratio of 7:5:3.

[0032] The water-retaining agent is a mixture of methylcellulose, hydroxypropylmethylcellulose and hydroxyethylmethylcellulose with a mass ratio of 8:6:3.

[0033] The preparation method of papermaking cooking aid is as follows:

[0034] Put deionized water into a stirring tank, heat up to 55°C, add water retaining agent while stirring, stir until completely dissolved, then add green oxygen, surfactant, sodium polyaspartate and sodium phosphate in sequence, dissolve completely Can.

Embodiment 3

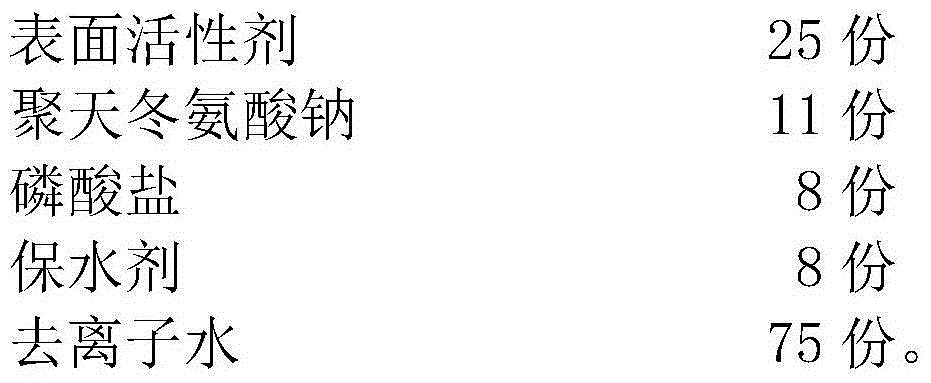

[0036] Weigh the following raw materials in parts by weight:

[0037]

[0038] The surfactant is a mixture of alkyl glucoside, sodium dodecylbenzenesulfonate and tea saponin with a mass ratio of 6:4:2.

[0039] The water retaining agent is a mixture of methylcellulose, hydroxypropylmethylcellulose and hydroxyethylmethylcellulose with a mass ratio of 7:5:2.

[0040] The preparation method of papermaking cooking aid is as follows:

[0041] Put deionized water into the stirring tank, heat up to 50°C, add water retaining agent while stirring, stir until completely dissolved, then add green oxygen, surfactant, sodium polyaspartate and potassium phosphate in sequence, dissolve completely Can.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com