Preparation method of demulsifier

A demulsifier, stirring and mixing technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of difficult dehydration of crude oil, difficulty of demulsifier demulsification, etc., and achieve strong wetting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

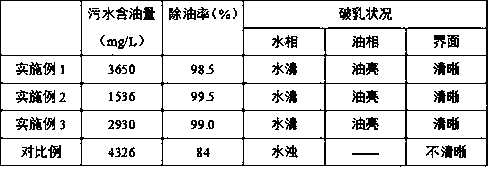

Examples

preparation example Construction

[0018] A preparation method of demulsifier, comprising the steps of:

[0019] (1) Take tert-butylphenol and add tetrapentapentaamine at a mass ratio of 2:5, heat up to 90-100°C and stir and mix for 30-40 minutes to obtain a mixed solution. Take the mixed solution and add formaldehyde at a mass ratio of 100:3. Stir and mix at 35~40°C for 2~3 hours, then add xylene with a mass of 50~60% of the mixed liquid, raise the temperature to 95~100°C, stir and mix for 3~4 hours, and rotate to evaporate to obtain the rotary evaporated product;

[0020] (2) Take the rotary evaporator and add potassium hydroxide at a mass ratio of 10:1, pass through nitrogen protection, vacuumize for 20~30min, then add propylene oxide with 20~30% of the rotary evaporator, heat up to 0.3MPa Stir and mix at 120~130°C for 3~4 hours to obtain a stirred mixture. Take the stirred mixture and add acetic acid solution with a concentration of 0.1mol / L at a mass ratio of 12:1 and stir and mix to obtain a mixture. Take...

Embodiment 1

[0025] A preparation method of demulsifier, comprising the steps of:

[0026] (1) Take tert-butylphenol and add tetrapentapentaamine at a mass ratio of 2:5, heat up to 90°C and stir and mix for 30 minutes to obtain a mixed solution, take the mixed solution and add formaldehyde at a mass ratio of 100:3, stir and mix at 35°C 2h, then add xylene with 50% mass of the mixed solution, raise the temperature to 95°C, stir and mix for 3h, and rotovap to obtain the rotoevaporator;

[0027] (2) Take the rotary evaporator and add potassium hydroxide at a mass ratio of 10:1, pass through nitrogen protection, vacuumize for 20 minutes, then add propylene oxide with 20% mass of the rotary evaporator, heat up to 120°C at 0.3MPa, stir and mix 3h, to obtain a stirred mixture, take the stirred mixture and add acetic acid solution with a concentration of 0.1mol / L at a mass ratio of 12:1 and stir and mix to obtain a mixture, take the mixture and extract it with dichloromethane, take the extract and...

Embodiment 2

[0032] A preparation method of demulsifier, comprising the steps of:

[0033] (1) Take tert-butylphenol and add tetrapentapentaamine at a mass ratio of 2:5, heat up to 100°C and stir and mix for 40 minutes to obtain a mixed solution, take the mixed solution and add formaldehyde at a mass ratio of 100:3, stir and mix at 40°C 3h, then add xylene with 60% mass of the mixed solution, raise the temperature to 100°C, stir and mix for 4h, and then rotovap to obtain a rotoevaporator;

[0034] (2) Take the rotary evaporator and add potassium hydroxide at a mass ratio of 10:1, pass through nitrogen protection, vacuumize for 30 minutes, then add propylene oxide with a mass of 30% of the rotary evaporator, heat up to 130°C at 0.3MPa, stir and mix 4h, to obtain a stirred mixture, take the stirred mixture and add acetic acid solution with a concentration of 0.1mol / L at a mass ratio of 12:1 and stir and mix to obtain a mixture, take the mixture and extract it with dichloromethane, take the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com