Method for producing methane and preparing fertilizer simultaneously

A technology for preparing fertilizers and producing methane, which is applied to the preparation of organic fertilizers, organic fertilizers, and excretion fertilizers. It can solve the problems of large differences in nutrient content of fermentation products, slow reaction start-up speed, and low nutrient content in effective states. Concentration ammonia inhibits fermentation and organic acid accumulation problems, improves composition and structure, increases porosity and specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Mix 8.16 kg of pig manure and 1.84 kg of straw to obtain a mixed material, the solid content of the mixed material is 27.0%, the VS is 19.3%, and the C / N is 20;

[0038] (2) Mix 1kg of rice straw charcoal obtained by carbonization at 300°C with 10kg of the above mixture, place it in a 20L anaerobic fermentation tank, and feed nitrogen into the anaerobic fermentation tank for 10 minutes to exhaust the headspace of the reactor The air ensures an anaerobic environment for the reaction, and the fermentation temperature is 55°C;

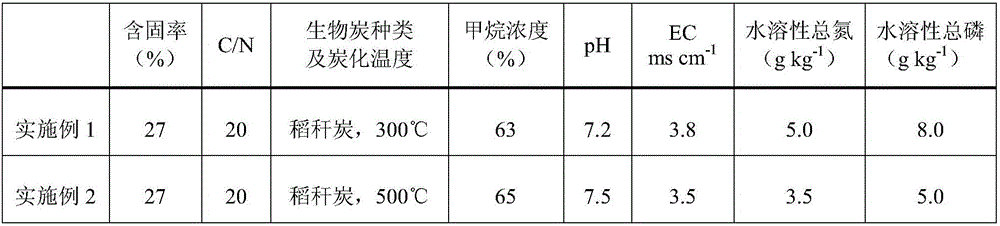

[0039] Using the above treatment method, during the continuous culture process of dry methane fermentation, the average methane volume concentration in the biogas produced within 50 days was analyzed every 1 to 5 days, and the biogas residue samples were collected to analyze the water-soluble nitrogen and phosphorus content, pH value and EC value. The results are shown in Table 2. Among them, the methane volume concentration data analyzed ever...

Embodiment 2

[0041](1) Mix 8.16 kg of pig manure and 1.84 kg of straw to obtain a mixed material, the solid content of the mixed material is 27.0%, the VS is 19.3%, and the C / N is 20;

[0042] (2) Mix 1 kg of rice straw charcoal obtained by carbonization at 500 °C with the above 10 kg mixture, place it in a 20L anaerobic fermentation tank, and feed nitrogen into the anaerobic fermentation tank for 10 minutes to exhaust the head space of the reactor The air ensures an anaerobic environment for the reaction, and the fermentation temperature is 55°C;

[0043] Using the above treatment method, during the continuous culture process of dry methane fermentation, the average methane volume concentration in the biogas produced within 50 days was analyzed every 1 to 5 days, and the biogas residue samples were collected to analyze the water-soluble nitrogen and phosphorus content, pH value and EC value. The results are shown in Table 2. The results showed that during the 50-day fermentation process,...

Embodiment 3

[0045] (1) Mix 8.16 kg of pig manure and 1.84 kg of straw to obtain a mixed material, the solid content of the mixed material is 27.0%, the VS is 19.3%, and the C / N is 20;

[0046] (2) Mix 1kg of rice straw charcoal obtained by carbonization at 700°C with the above 10kg mixture, place it in a 20L anaerobic fermentation tank, and feed nitrogen into the anaerobic fermentation tank for 10 minutes to exhaust the head space of the reactor The air ensures an anaerobic environment for the reaction, and the fermentation temperature is 55°C;

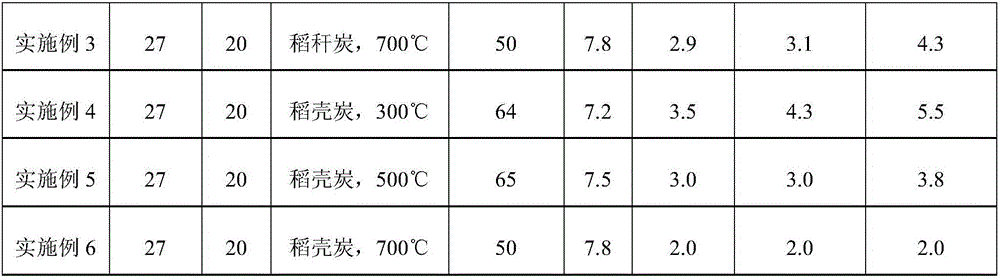

[0047] Using the above treatment method, during the continuous culture process of dry methane fermentation, the average methane volume concentration in the biogas produced within 50 days was analyzed every 1 to 5 days, and the biogas residue samples were collected to analyze the water-soluble nitrogen and phosphorus content, pH value and EC value. The results are shown in Table 2. The results show that during the 50-day fermentation process, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com