Method for producing methane through high-temperature dry type anaerobic co-fermentation

A dry anaerobic and co-fermentation technology, applied in the field of fermentation, can solve the problems of organic acid accumulation, uneven mixing of reaction substrates, poor stability of the decomposition rate system, etc., and achieve the effect of slowing down the accumulation of organic acids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Mix 8.16 kg of pig manure and 1.84 kg of rice straw to obtain a mixed material, the solid content of the mixed material is 27.0%, the VS is 19.3%, and the C / N is 20;

[0037] (2) The inoculum of 10kg and the above-mentioned 10kg mixed material are placed in a 20L anaerobic fermenter, and nitrogen is passed into the anaerobic fermenter for 10min to exhaust the air in the reactor headspace to ensure the anaerobic reaction Environment, culture temperature is 55°C;

[0038] (3) SRT is set to 40 days.

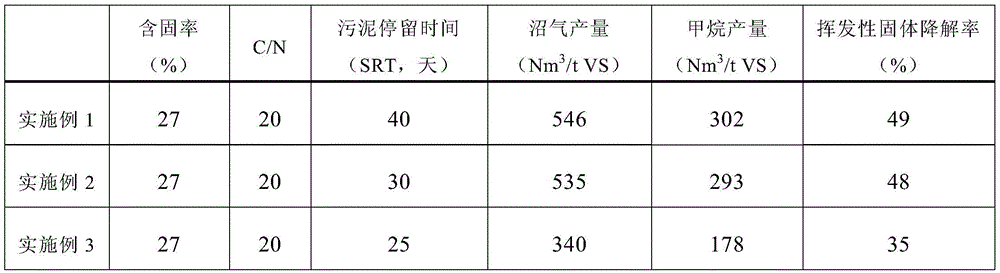

[0039] In the high-temperature dry anaerobic co-fermentation continuous culture process, the SRT was 40 days, and the average biogas production, average methane production and volatile solid degradation rate in this process were analyzed every 1 to 5 days. The results are shown in Table 2. The results showed that during the 100-day fermentation process, the average biogas production was 546Nm 3 / t-VS, the average output of methane is 302Nm 3 / t-VS, the concentration of...

Embodiment 2

[0041] (1) Mix 8.16 kg of pig manure and 1.84 kg of rice straw to obtain a mixed material, the solid content of the mixed material is 27.0%, the VS is 19.3%, and the C / N is 20;

[0042] (2) The inoculum of 10kg and the above-mentioned 10kg mixed material are placed in a 20L anaerobic fermenter, and nitrogen is passed into the anaerobic fermenter for 10min to exhaust the air in the reactor headspace to ensure the anaerobic reaction Environment, culture temperature is 55°C;

[0043] (3) SRT is set to 30 days.

[0044]In the continuous culture process of high-temperature dry anaerobic co-fermentation, the SRT was 30 days, and the average biogas production, average methane production and volatile solid degradation rate in the anaerobic fermentation process were analyzed every 1 to 5 days. The results are shown in Table 2. The results showed that during the 100-day fermentation process, the average biogas production was 535Nm 3 / t-VS, the average methane production is 293Nm 3 / t...

Embodiment 3

[0046] (1) Mix 8.16 kg of pig manure and 1.84 kg of rice straw to obtain a mixed material, the solid content of the mixed material is 27.0%, the VS is 19.3%, and the C / N is 20;

[0047] (2) The inoculum of 10kg and the above-mentioned 10kg mixed material are placed in a 20L anaerobic fermenter, and nitrogen is passed into the anaerobic fermenter for 10min to exhaust the air in the reactor headspace to ensure the anaerobic reaction Environment, culture temperature is 55°C;

[0048] (3) SRT is set to 25 days.

[0049] In the high-temperature dry anaerobic co-fermentation continuous culture process, the SRT was 25 days, and the average biogas production, average methane production and volatile solid degradation rate in this process were analyzed every 1 to 5 days. The results are shown in Table 2. The results show that during the 100-day system fermentation process, the average biogas production is 340Nm 3 / t-VS, methane average production 178Nm 3 / t-VS, the concentration of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com